Geo-polymer recycled concrete and preparation method thereof

A technology of geopolymer and recycled concrete, applied in the field of construction, to achieve the effect of reducing production energy consumption and resource consumption, reducing mining and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

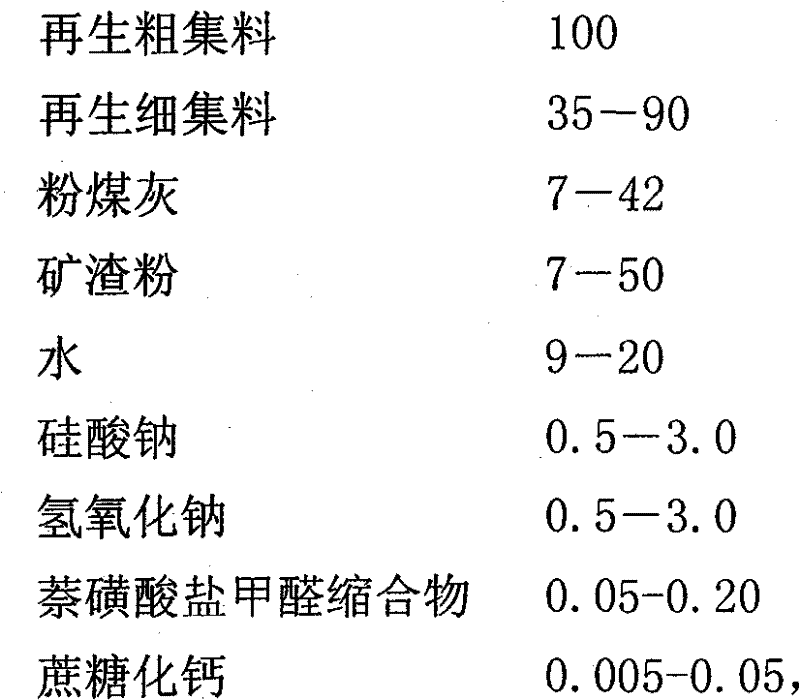

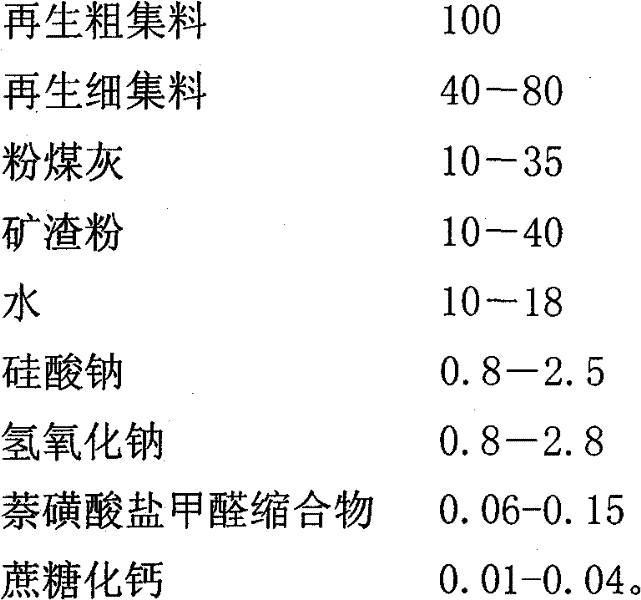

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: Geopolymer recycled concrete is prepared by the following weight ratio: recycled coarse aggregate 100, recycled fine aggregate 40, fly ash 10, slag powder 10, water 10, sodium silicate 0.8, sodium hydroxide 2.8 , naphthalenesulfonate formaldehyde condensate 0.06, calcium sucrose 0.01. The prepared geopolymer recycled concrete has a slump of 13cm, an initial setting time of 6h25min, a final setting time of 7h40min, a 3d compressive strength of 22.5MPa after hardening, a 28d compressive strength of 31.2MPa, and an impermeability grade of P12. After soaking in 5% HCl for 3 months, the strength loss rate is 12%, and the thermal conductivity is 2.3W / m·K.

Embodiment 2

[0049]Embodiment 2: Geopolymer recycled concrete is prepared according to the following weight ratio: recycled coarse aggregate 100, recycled fine aggregate 80, fly ash 35, slag powder 40, water 18, sodium silicate 2.5, sodium hydroxide 2.8 , naphthalenesulfonate formaldehyde condensate 0.15, calcium sucrose 0.04. The prepared geopolymer recycled concrete has a slump of 24cm, an initial setting time of 8h05min, a final setting time of 11h10min, a 3d compressive strength of 53.5MPa after hardening, a 28d compressive strength of 68.6MPa, and an impermeability grade of P18. After soaking in 5% HCl for 3 months, the strength loss rate is 0.2%, and the thermal conductivity is 2.4W / m·K.

Embodiment 3

[0050] Embodiment 3: Geopolymer recycled concrete is prepared according to the following weight ratio: recycled coarse aggregate 100, recycled fine aggregate 70, fly ash 25, slag powder 20, water 16, sodium silicate 1.7, sodium hydroxide 0.8 , naphthalenesulfonate formaldehyde condensate 0.09, calcium sucrose 0.02. The prepared geopolymer recycled concrete has a slump of 19cm, an initial setting time of 7h25min, a final setting time of 9h35min, a 3d compressive strength of 47.2MPa after hardening, a 28d compressive strength of 56.0MPa, and an impermeability grade of P17. After soaking in 5% HCl for 3 months, the strength loss rate is 2.3%, and the thermal conductivity is 2.3W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com