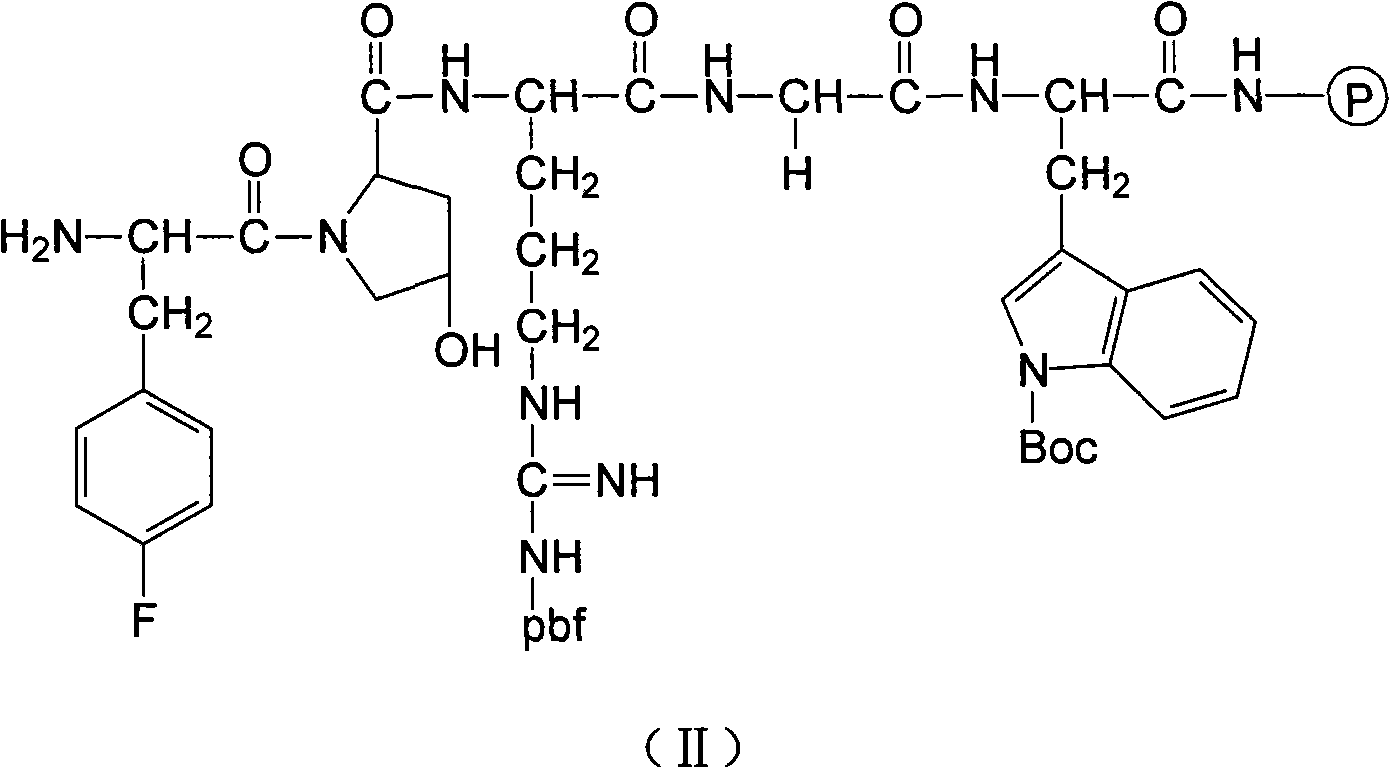

Polyethylene glycol modified nemifitide and preparation method

A technology of nanopeptide and polyethylene glycol, which is applied in the field of peptide or protein modification and its preparation, can solve the problems of unstable physical and chemical properties and reduced bioavailability, achieve single product, long half-life, and improve biological The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

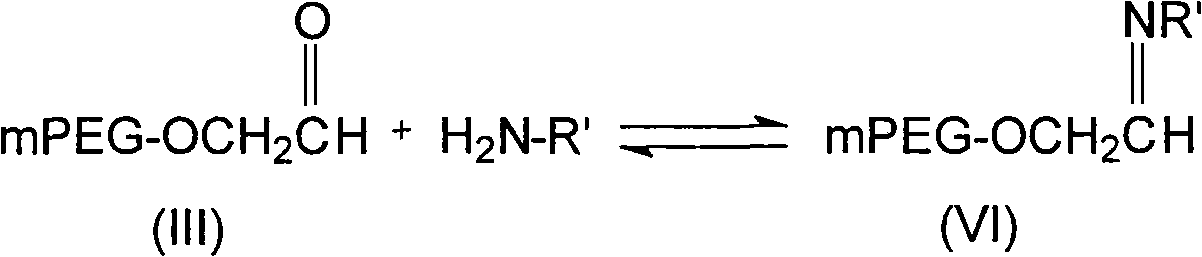

[0042] Preparation method of PEG-modified nano-non-peptide complexes. In this example, the PEG is mPEG-CH 2 CHO, with a molecular weight of 2KD.

[0043] In the first step, the nano-non-peptide precursor was prepared with 0.1 mmol of Rink Amide MBHA resin;

[0044] In the second step, 0.1 mmol of mPEG-CH with a molecular weight of 2KD 2 CHO was dissolved in 150 mmol pH 6 DMF solution, the nano-non-peptide precursor prepared in the first step was added, mixed to form a reaction mixture, and the reaction was carried out at 20 °C for 6 h;

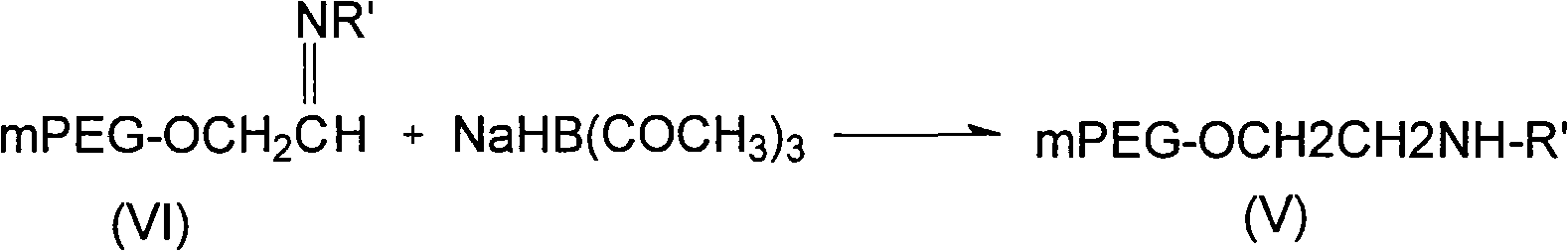

[0045] In the third step, 0.1 mmol of sodium triacetoxyborohydride was slowly added to the reaction system of the second step, and the reaction was continued for 6 h;

[0046]After the fourth step, the PEG-coupled resin was repeatedly washed with methanol to remove unreacted sodium triacetoxyborohydride and mPEG-CH3CHO, etc., and the resin and amino acid side chain protecting groups were cleaved, precipitated with glacial ether, and frozen....

Embodiment 2

[0049] Preparation method of PEG-modified nano-non-peptide complexes. In this example, the PEG is mPEG-CH 2 CHO, with a molecular weight of 2KD.

[0050] The first step is to prepare the nano-non-peptide precursor with 0.1 mmol of RinkAmide MBHA resin;

[0051] In the second step, 0.1 mmol of mPEG-CH with a molecular weight of 2KD 2 CHO was dissolved in 150 mmol pH 6 DMF solution, the nano-non-peptide precursor prepared in the first step was added, mixed to form a reaction mixture, and the reaction was carried out at 60 °C for 6 h;

[0052] In the third step, 0.1 mmol of sodium triacetoxyborohydride was slowly added to the reaction system of the second step, and the reaction was continued for 18 h;

[0053] After the fourth step, the PEG-coupled resin was repeatedly washed with methanol to remove unreacted sodium triacetoxyborohydride and mPEG-CH3CHO, etc., and the resin and amino acid side chain protecting groups were cleaved, precipitated with glacial ether, and frozen. ...

Embodiment 3

[0056] Preparation method of PEG-modified nano-non-peptide complexes. In this example, the PEG is mPEG-CH 2 CHO, with a molecular weight of 2KD.

[0057] The first step is to prepare the nano-non-peptide precursor with 0.1 mmol of RinkAmide MBHA resin;

[0058] In the second step, 0.1 mmol of mPEG-CH with a molecular weight of 2KD 2 CHO was dissolved in 150 mmol pH 6 DMF solution, the nano-non-peptide precursor prepared in the first step was added, mixed to form a reaction mixture, and the reaction was carried out at 90 °C for 6 h;

[0059] In the third step, 0.1 mmol of sodium triacetoxyborohydride was slowly added to the second step reaction system, and the reaction was continued for 30h;

[0060] After the fourth step, the PEG-coupled resin was repeatedly washed with methanol to remove unreacted sodium triacetoxyborohydride and mPEG-CH3CHO, etc., and the resin and amino acid side chain protecting groups were cleaved, precipitated with glacial ether, and frozen. After dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com