Superparamagnetic core-shell composite nanoparticle and preparation method thereof

A composite nanoparticle and superparamagnetic technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of magnetic property change, structural change, instability, etc., and achieve the effect of simple process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1), weigh 1.0g of MnFe with an average particle size of 30nm 2 o 4 The particles were dispersed in 50 g of deionized water, 5 ml of 25 wt % tetramethylammonium hydroxide solution was added dropwise under stirring, and then ultrasonically dispersed for 30 min to form a stable suspension.

[0032] (2) Take 0.5ml of the above suspension and disperse it in a mixed solution of 5ml of water and 50ml of absolute ethanol, transfer it to a three-necked flask, and stir for 10min.

[0033] (3) Add 5ml of 25wt% ammonia water into the three-necked bottle, and stir to make it evenly mixed.

[0034] (4) Mix 0.25ml tetraethyl orthosilicate and 50ml absolute ethanol evenly, place it in a dropping funnel, and add it dropwise into a three-necked flask, and the reaction process is accompanied by stirring.

[0035] (5) Aging at room temperature for 20 h after completion of the dropwise addition to complete the reaction.

[0036] (6), isolate the product, wash and filter, and dry to obta...

Embodiment 2

[0038] (1), weigh 1.5g of MnFe with an average particle size of 30nm 2 o 4 The particles were dispersed in 50 g of deionized water, 5 ml of 25 wt % tetramethylammonium hydroxide solution was added dropwise under stirring, and then ultrasonically dispersed for 30 min to form a stable suspension.

[0039] (2) Take 1.0ml of the above suspension and disperse it in a mixed solution of 4ml of water and 50ml of absolute ethanol, transfer it to a three-neck flask, and stir for 10min.

[0040] (3) Add 6ml of 25wt% ammonia water into the three-necked bottle, and stir to make it evenly mixed.

[0041] (4) Mix 0.5ml tetraethyl orthosilicate and 50ml absolute ethanol evenly, place it in a dropping funnel, and add it dropwise into a three-necked flask, and the reaction process is accompanied by stirring.

[0042] (5) Aging at room temperature for 24 hours after completion of the dropwise addition to complete the reaction.

[0043] (6), with embodiment 1.

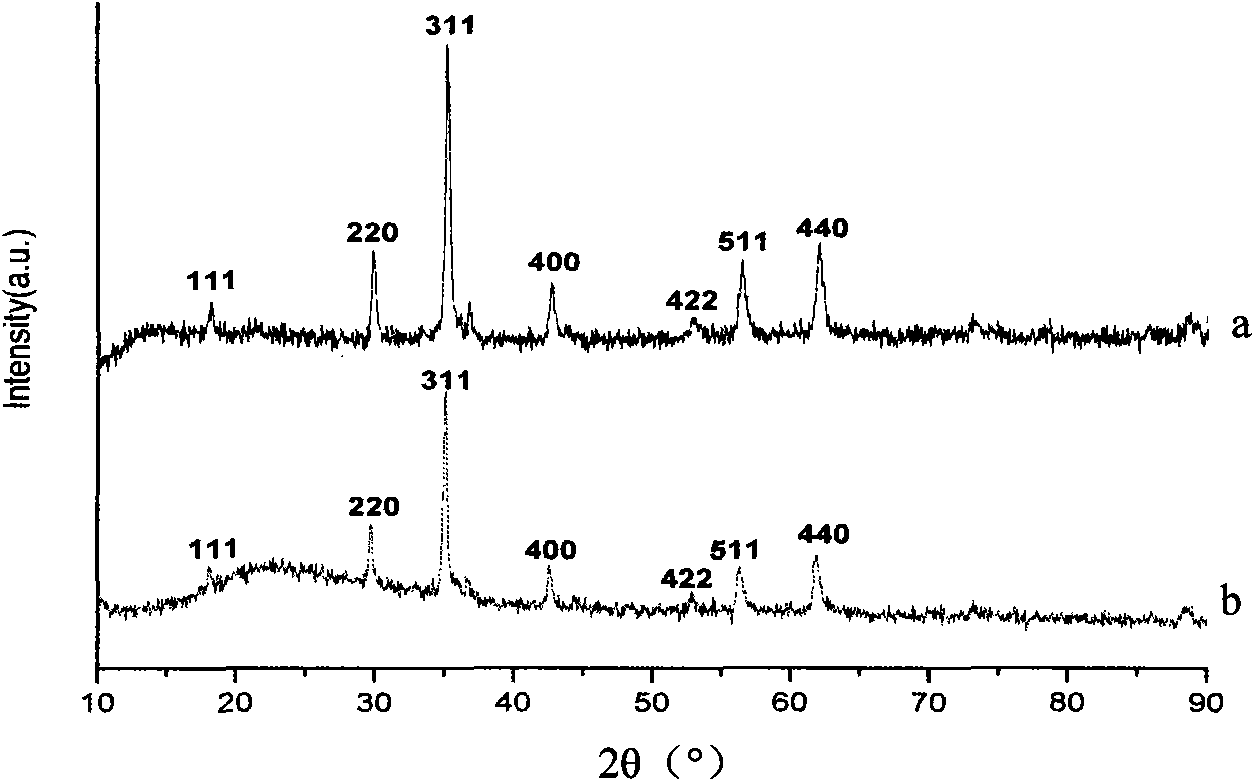

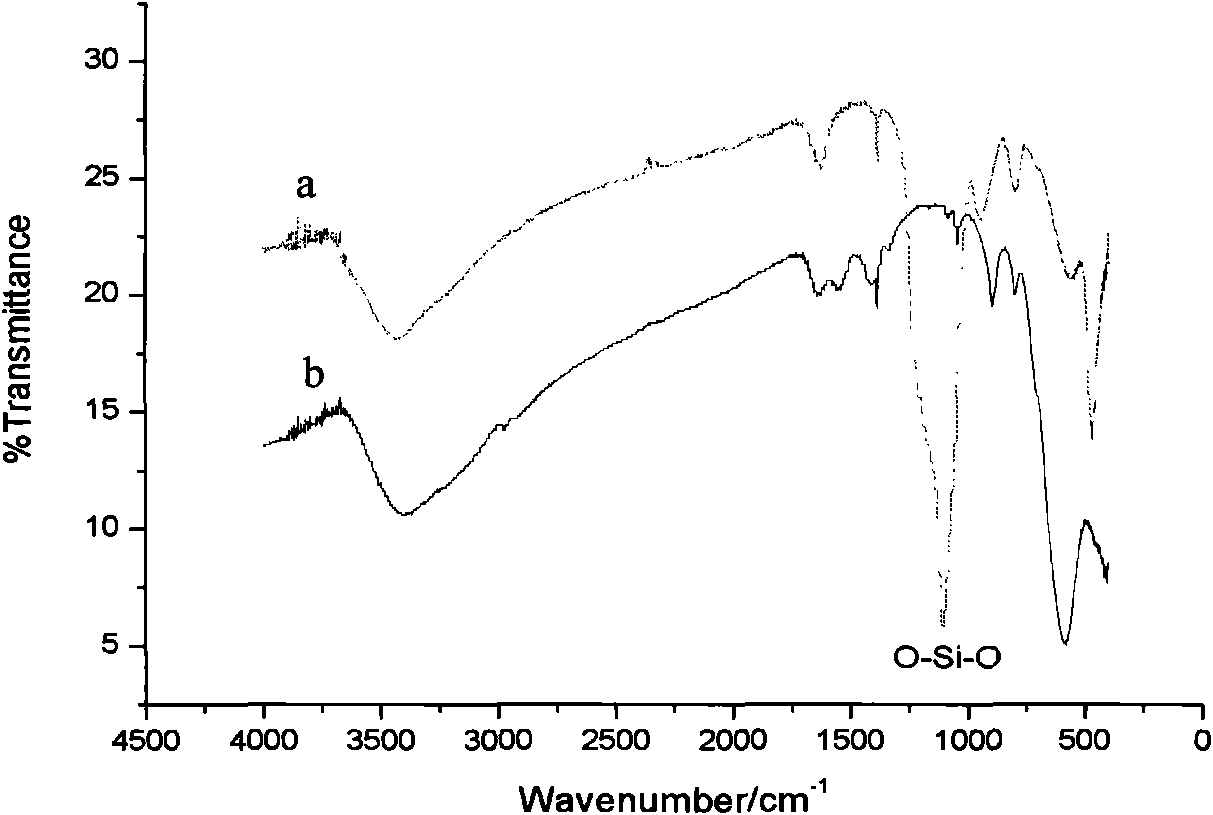

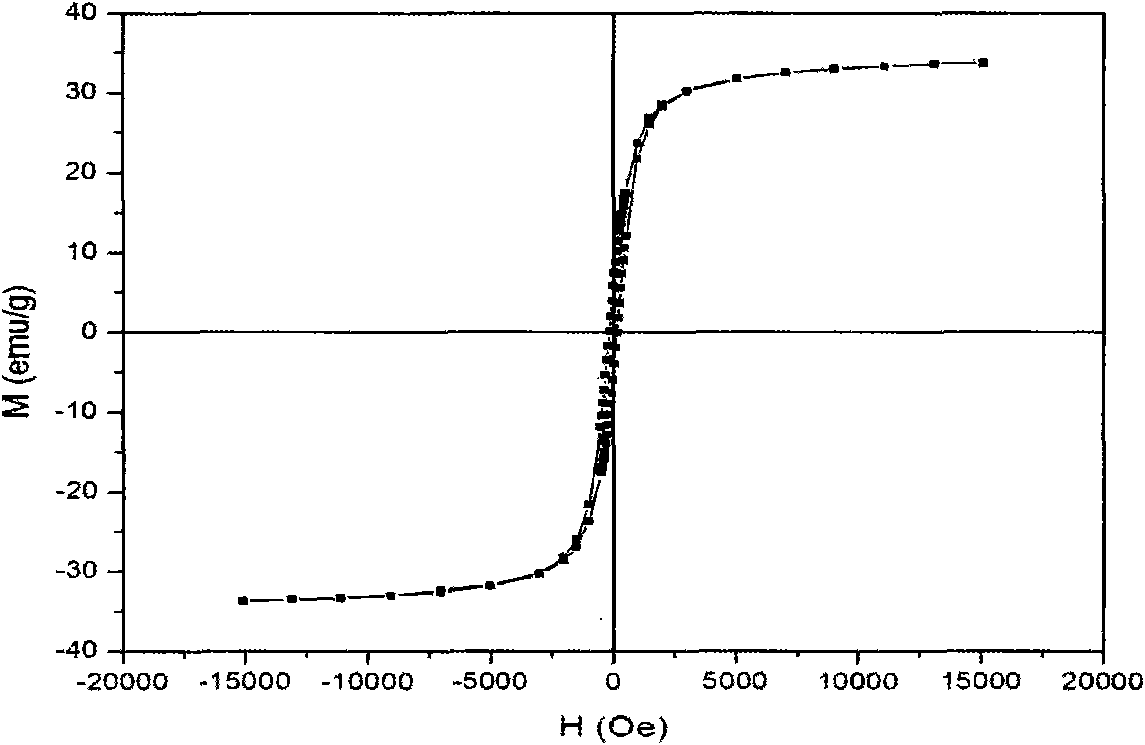

[0044] figure 1 It is the X-r...

Embodiment 3

[0048] (1), weigh 1.5g of MnFe with an average particle size of 30nm 2 o 4 The particles were dispersed in 50 g of deionized water, 5 ml of 25 wt % tetramethylammonium hydroxide solution was added dropwise under stirring, and then ultrasonically dispersed for 30 min to form a stable suspension.

[0049] (2) Take 1.0ml of the above suspension and disperse it in a mixed solution of 4ml of water and 50ml of absolute ethanol, transfer it to a three-neck flask, and stir for 10min.

[0050] (3) Add 6ml of 25wt% ammonia water into the three-necked bottle, and stir to make it evenly mixed.

[0051] (4) Mix 2ml of tetraethyl orthosilicate and 50ml of absolute ethanol evenly, place it in a dropping funnel, and add it dropwise into a three-necked flask, and the reaction process is accompanied by stirring.

[0052] (5), (6), with embodiment 1.

[0053] Figure 6 It is the TEM topography of the composite particles prepared under the process conditions of this example. It can be seen f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com