Method for preparing substrate with gallium-doped zinc oxide texture and substrate prepared by the same

A gallium-doped zinc oxide and substrate technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the adverse effects of photoelectric conversion efficiency of silicon thin film solar cells, and the inability of suede tin oxide film to withstand Affected by continuous bombardment, light-induced attenuation cannot be effectively reduced or suppressed, etc., to achieve the effect of strong resistance to hydrogen plasma bombardment, adjustable light trapping ability, and reduced attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

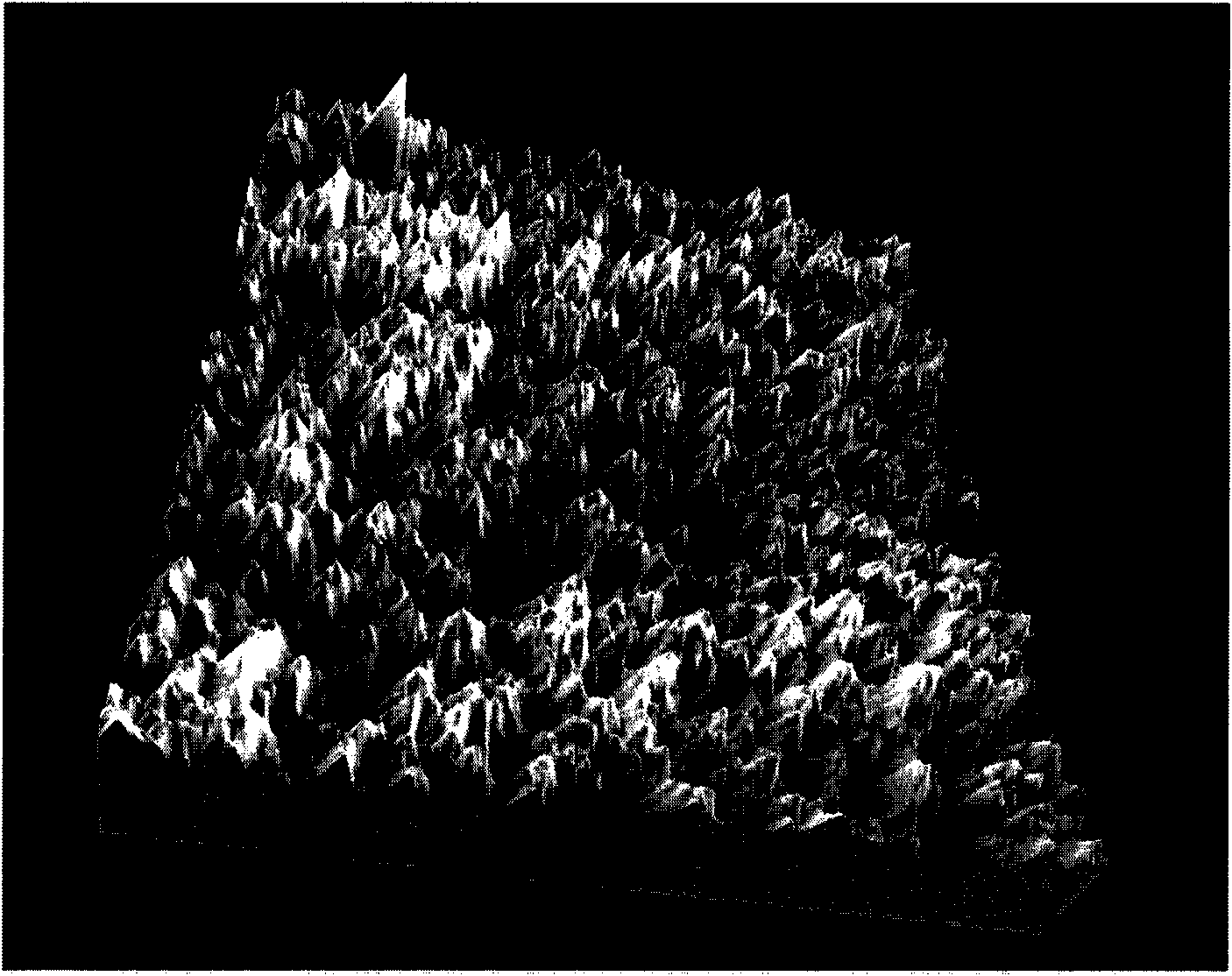

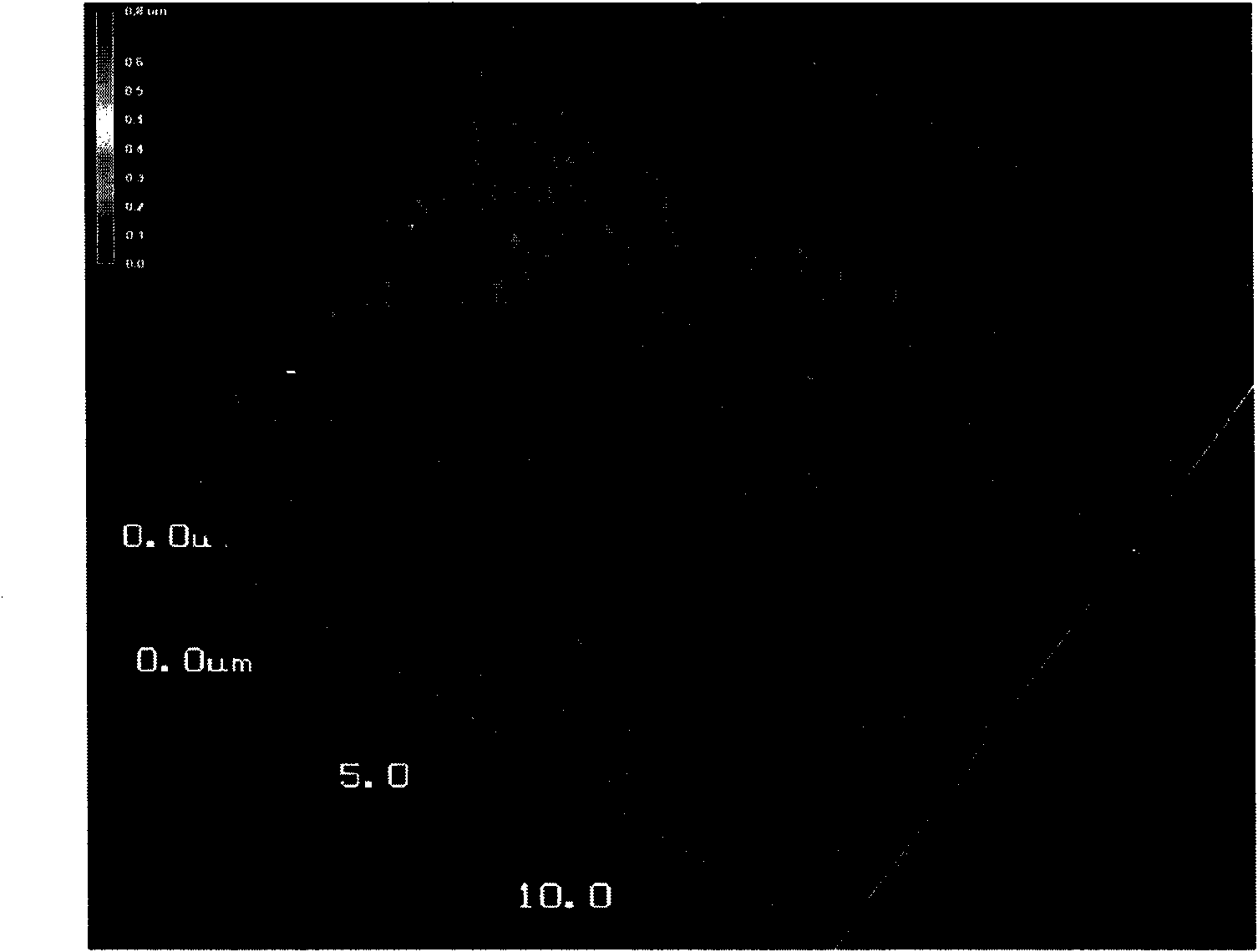

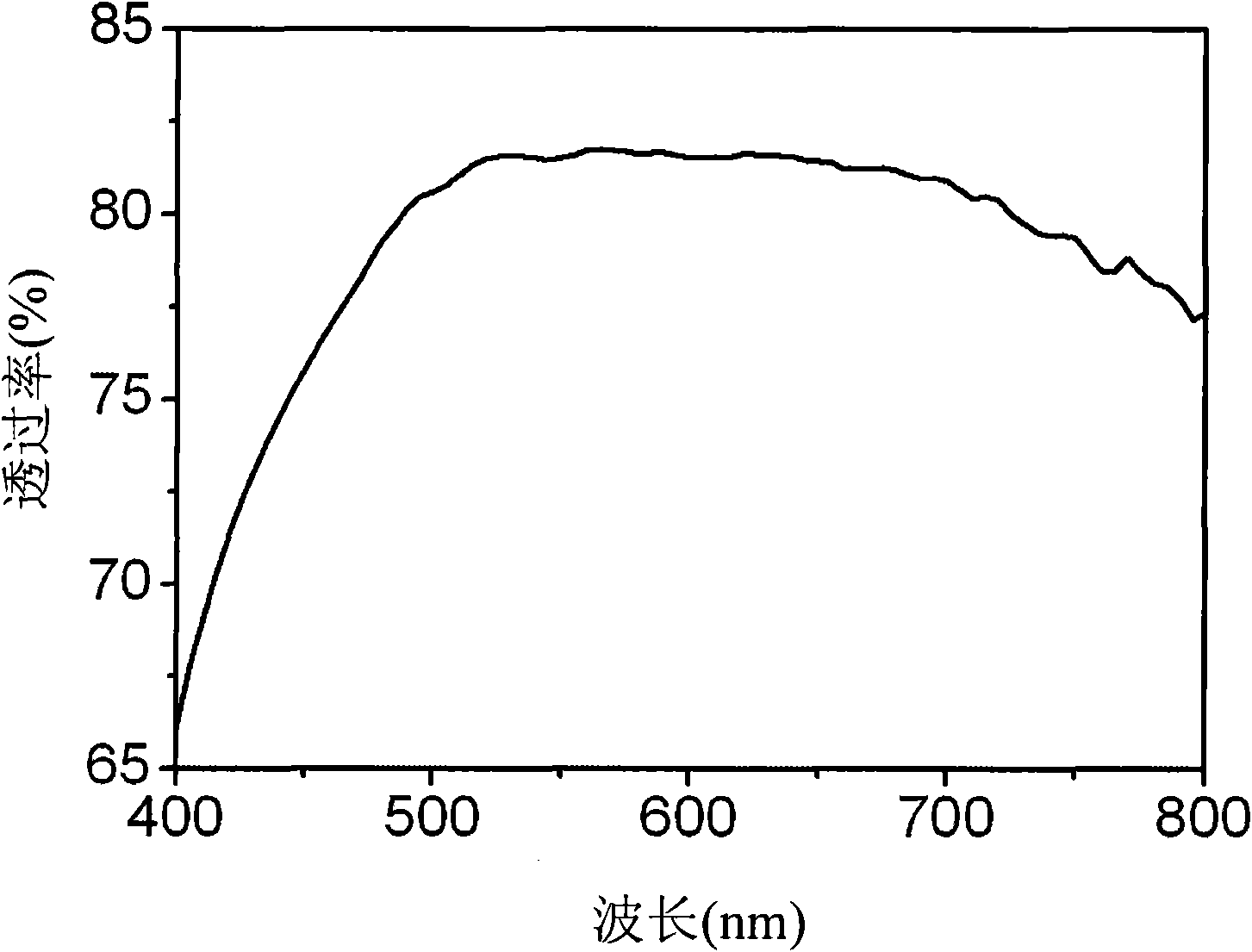

Embodiment 1

[0035] Adopt the method provided by the present invention to prepare the glass substrate with the gallium-doped zinc oxide textured surface, the specific operation steps are as follows:

[0036] 1) Clean the ordinary float glass substrate (purchased from Changshu Yaopi Special Glass Co., Ltd.) by high-pressure spray cleaning agent;

[0037] 2) The cleaned glass is placed in a radio frequency (13.56MHz) magnetron sputtering coating machine (purchased from Applied Materials Co., Ltd.), and the sputtering target used is a doped gallium oxide with a concentration of 2.5wt%. Gallium zinc oxide, the argon pressure is 4mtorr, the sputtering power is 250W, and the substrate temperature is 100°C, so as to prepare a gallium-doped zinc oxide film with an initial thickness of 900nm;

[0038]3) Soak the gallium-doped zinc oxide film prepared above in an acidic etching solution for 40s, the concentration of hydrochloric acid in the etching solution is 0.4wt%, the concentration of oxalic aci...

Embodiment 2~4

[0042] Except for the conditions in Table 1 below, other conditions were the same as in Example 1 to prepare a glass substrate with gallium-doped zinc oxide texture.

[0043] Table 1

[0044]

serial number

Substrate

Sputtering target

Medium trioxide

digallium concentration

(wt%)

pressure

(mtorr)

sputtering

the power

(W)

Substrate

temperature

(℃)

film

initial

thickness

(nm)

Etchant

composition

(wt%)

degree(℃)

to soak

time

(s)

Thin suede

Film thickness

(nm)

implement

example 1

float

Glass

2.5

4

250

100

900

Hydrochloric acid 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Root mean square roughness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com