Method utilizing microsomal enzyme of animal liver to biosynthesize 7-dehydrocholesterol

A technology for dehydrocholesterol and biosynthesis, which is applied in the fields of biochemical engineering and enzyme engineering, can solve the problems of low efficiency, difficult control of conditions, affecting the production cost of vitamin D, and marketing promotion of sales price, so as to reduce environmental pollution and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of microsomal enzyme solution

[0026] Put 50g of fresh pig liver cut into pieces into pH 5, 0.01mol / L glutathione phosphate buffer solution, homogenize with a tissue homogenizer at 4°C, filter with two layers of gauze, and place the filtrate in In the ultrasonic cell disruptor, the processing conditions are: power 400W, temperature 4°C, time 5min. Then centrifuge (4°C, 12000r min -1 , 10 min) separation, and the supernatant was taken to obtain the microsomal enzyme solution.

[0027] (2) Enzymatic conversion reaction

[0028] Add 20ml 1ug / ml squalene, 2ml 2mmol / L reduced coenzyme II, 1ml 5mmol / L adenosine triphosphate, 2ml 20mmol / L nicotinamide to the obtained 20ml microsomal enzyme solution, and react for 5 hours to obtain an enzymatic conversion reaction solution .

[0029] (3) Saponification reaction

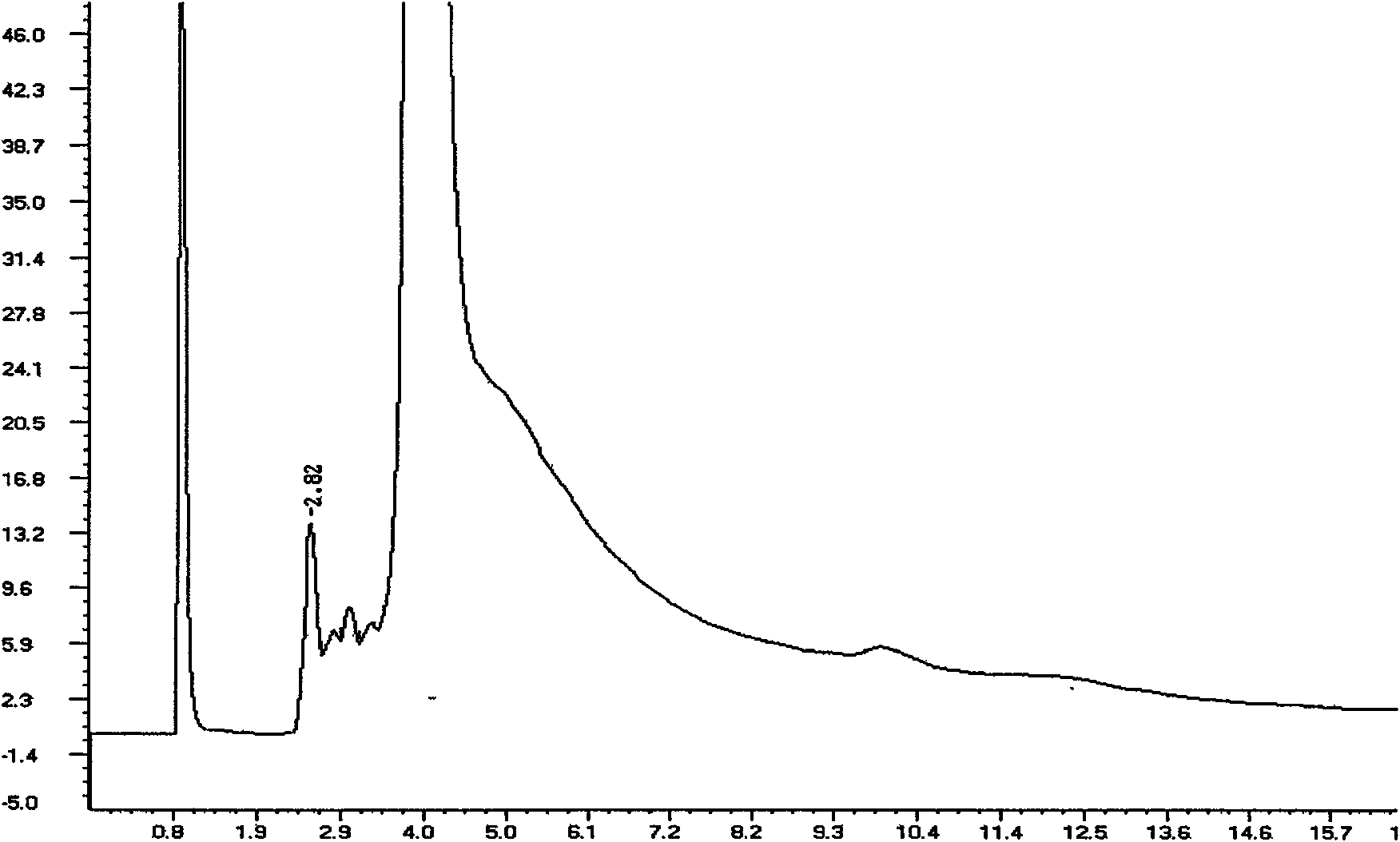

[0030] The enzymatic conversion reaction solution was added to 5 ml of 15% KOH-ethanol solution, and the reaction solution was shaken at 30° C. f...

Embodiment 2

[0034] (1) Preparation of microsomal enzyme solution

[0035] Put 50 g of fresh pig liver cut into pieces into pH 6.5, 0.05 mol / L glutathione phosphate buffer solution, homogenize it with a tissue homogenizer at 4°C, filter it with two layers of gauze, and place the filtrate in In the ultrasonic cell disruptor, the processing conditions are: power 150W, temperature 35°C, time 40min. Then centrifuge (4°C, 12000r min -1 , 10 min) separation, and the supernatant was taken to obtain the microsomal enzyme solution.

[0036] (2) Enzymatic conversion reaction

[0037] Add 20ml of 40ug / ml squalene, 2ml of 1mmol / L reduced coenzyme II, 1ml of 2.5mmol / L adenosine triphosphate, and 2ml of 30mmol / L nicotinamide to the obtained 20ml microsomal enzyme solution, and react for 5 hours to obtain an enzymatic conversion reaction liquid.

[0038] (3) Saponification reaction

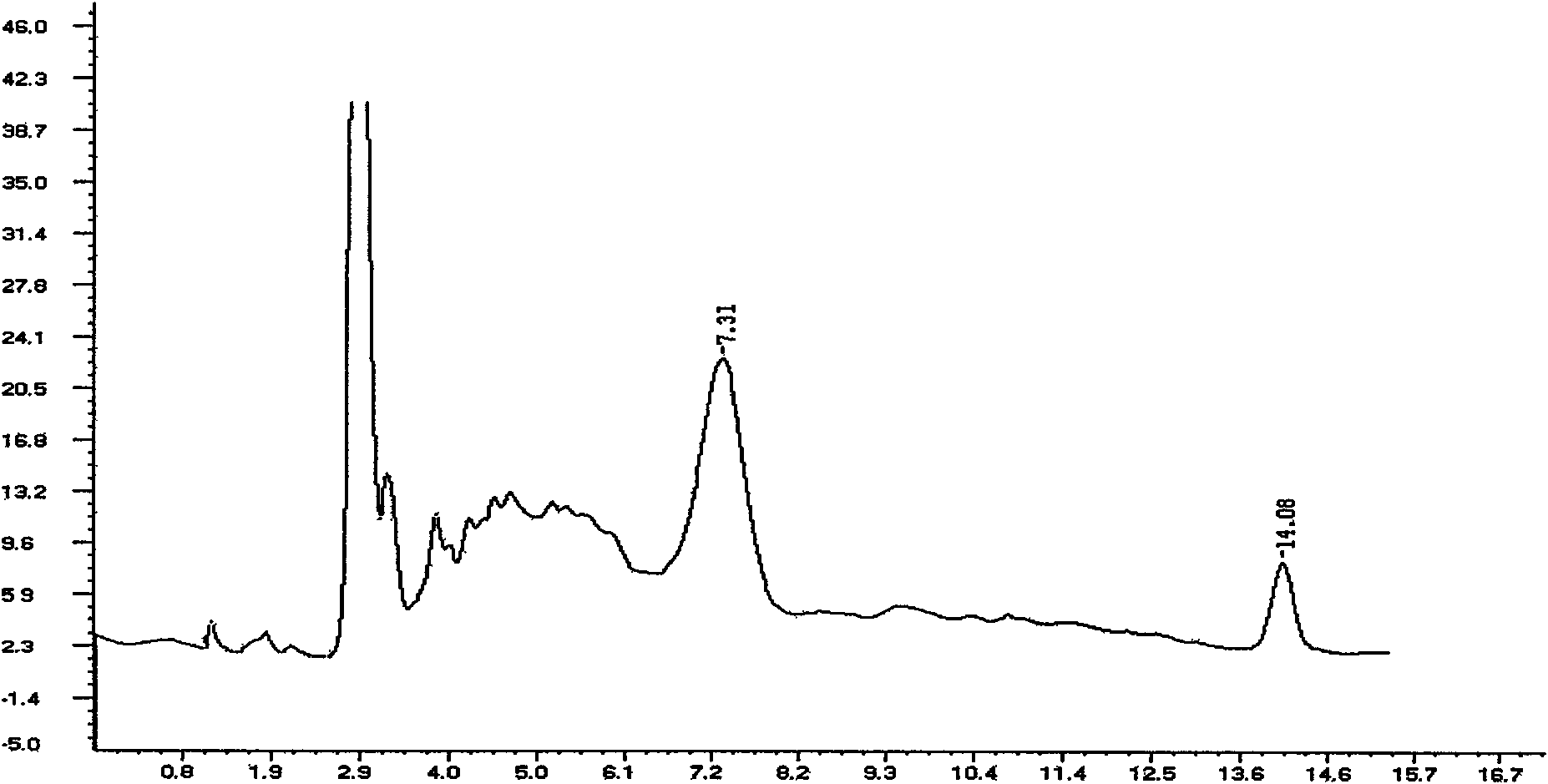

[0039] The enzymatic conversion reaction solution was added to 5 ml of 15% KOH-ethanol solution, and the reaction sol...

Embodiment 3

[0043] (1) Preparation of microsomal enzyme solution

[0044] Put 50 g of fresh sheep liver cut into pieces into pH 9, 0.05 mol / L glutathione phosphate buffer solution, homogenize it with a tissue homogenizer at 4°C, filter it with two layers of gauze, and place the filtrate in In the ultrasonic cell disruptor, the processing conditions are: power 300W, temperature 4°C, time 20min. Then centrifuge (4°C, 12000r min -1 , 10 min) separation, and the supernatant was taken to obtain the microsomal enzyme solution.

[0045] (2) Enzymatic conversion reaction

[0046] Add 20ml 40ug / ml squalene, 2ml 2mmol / L reduced coenzyme II, 1ml 5mmol / L adenosine triphosphate, 2ml 40mmol / L nicotinamide, 1ml 1mmol / L MgCL to the obtained 20ml microsomal enzyme solution 2 , and reacted for 5h to obtain an enzymatic conversion reaction liquid.

[0047] (3) Saponification reaction

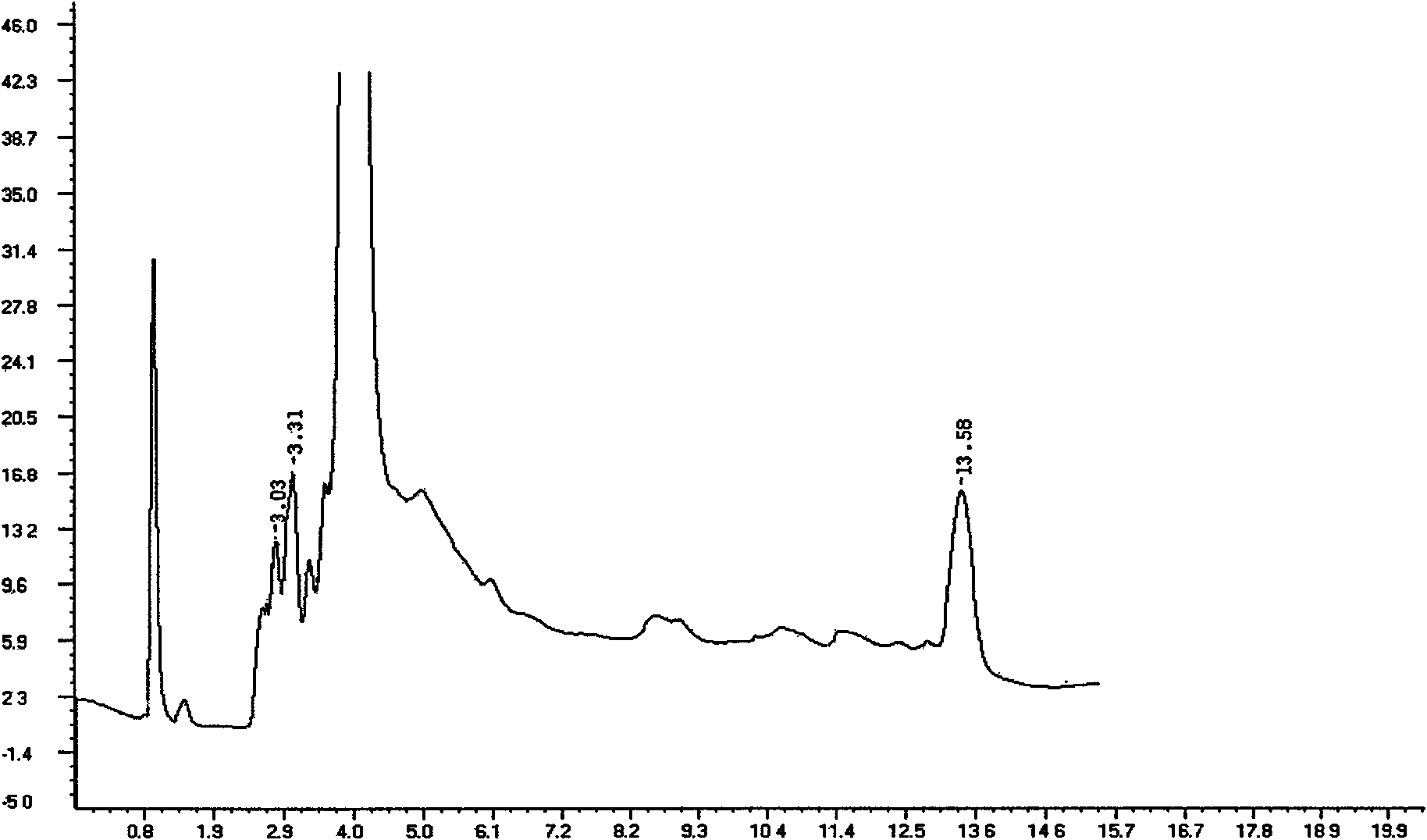

[0048] The enzymatic conversion reaction liquid was added to 5 ml of 15% KOH-ethanol solution, and the reaction was sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com