Crosslinkable polyethylene hot-melt adhesive composition and preparation method and application thereof

A technology of cross-linked polyethylene and hot melt adhesive, applied in the direction of non-polymer organic compound adhesives, adhesives, etc., can solve the problems of general chemical resistance and strength, low initial adhesion, low adhesion, etc. Improve temperature resistance and chemical stability, good bond strength, improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

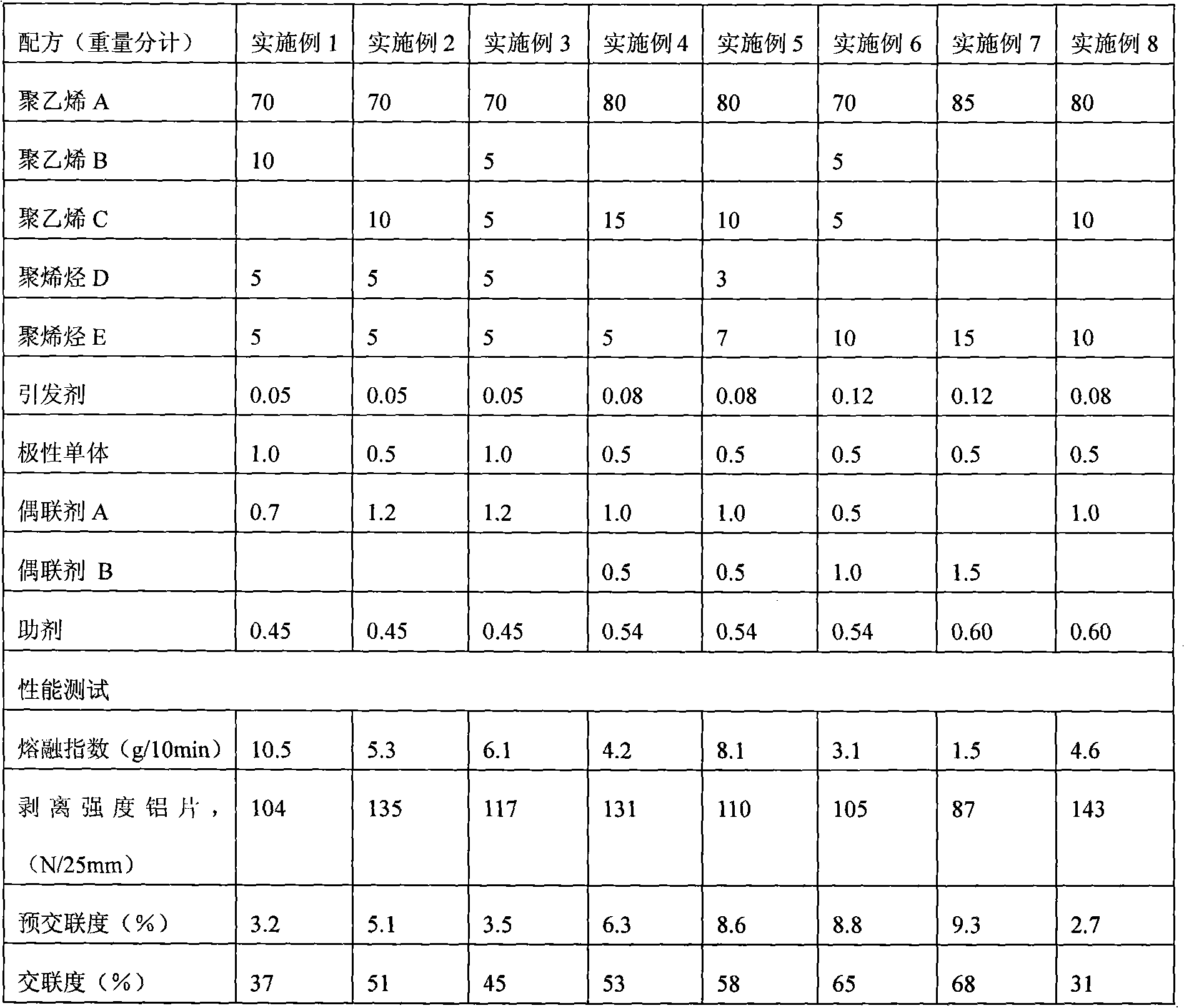

[0023] Add polyethylene and other polyolefins into polar monomers, silane coupling agents, initiators and other additives, weigh them and put them into a mixer for high-speed mixing for 3-5 minutes, then put them into a TE35 twin-screw extruder (long diameter In the ratio of 40:1), the temperature of the first zone of the extruder is 160°C, the temperature of the second zone is 180-190°C, the temperature of the third zone is 190-200°C, the temperature of the fourth-seventh zone is 200-210°C, and the temperature of the die head is 200-210°C , The melt temperature is 195-205°C, the screw speed is 30r / min, the strips are water-cooled after being ejected from the mold, blown dry, and cut into pellets to obtain the product, and its performance is tested. The specific experimental formula and test results are shown in Table 1.

[0024] Table 1. Embodiment 1~8 formula and test result

[0025]

[0026] Note: The melt index is tested according to GB / T3682; the peel strength is teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com