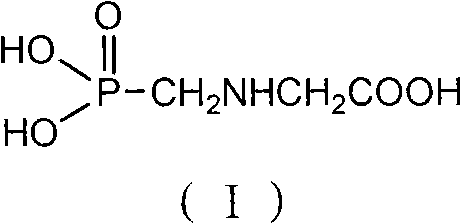

Novel process for recycling mother solution of glyphosate prepared by glycin method

A technology of glycine method and glyphosate, which is applied in the fields of chemicals for biological control, organic chemistry, herbicides and algicides, etc., can solve the problems of complex composition of mother liquor, high material consumption, quality degradation, etc., and achieve economical savings. The effect of input of raw materials and equipment, reduction of energy consumption and improvement of production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

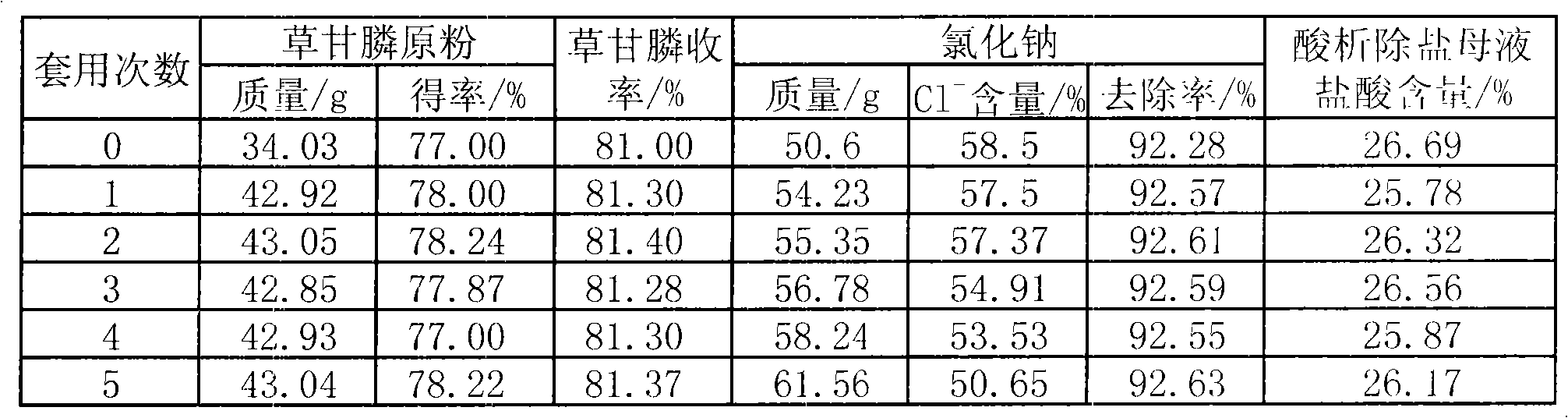

Embodiment 1

[0018] Adopt the method for comparative example 1 to prepare glyphosate crystallization mother liquor 75.5g, this mother liquor adds alkali and reclaims triethylamine to obtain mother liquor to be treated (hereinafter referred to as mother liquor to be treated), then passes into hydrogen chloride gas in this mother liquor to be treated, finally 143.9 g of solid-liquid mixture was obtained, and 50.6 g of crude sodium chloride was obtained after suction filtration, and 83.3 g of acid precipitation and desalination mother liquor. After chemical composition analysis, the hydrochloric acid content in the acid precipitation and desalination mother liquor is 26.69%, the chlorine content in the sodium chloride solid is 58.50%, and the acid precipitation desalination and sodium chloride removal rate is 92.28%. The acid precipitation and desalination mother liquor is reserved for the next batch Instead of hydrochloric acid, and according to the comparative example 1 acidification and hyd...

Embodiment 2

[0020] The method of Example 1 was used to treat the glyphosate crystallization mother liquor. Hydrogen chloride gas was introduced into the mother liquor to be treated, and finally 144.3 g of a solid-liquid mixture was obtained. After suction filtration, 51.5 g of crude sodium chloride was obtained, and 85.2 g of the mother liquor for acid precipitation and desalination. After chemical composition analysis, the hydrochloric acid content in the acid precipitation and desalination mother liquor is 27.23%, the chlorine content in the sodium chloride solid is 58.69%, and the acid precipitation desalination and sodium chloride removal rate is 92.34%. The acid precipitation and desalination mother liquor is reserved for the next batch Instead of hydrochloric acid, and according to the comparative example 1 acidification and hydrolysis part recycling.

Embodiment 3

[0022] Adopt the method for contrasting example 1 to prepare glyphosate, replace the hydrochloric acid acidification process esterification product with the acid precipitation desalting mother liquor of embodiment 1 gained during acidification, after deacidification, add water, cooling and crystallization, get glyphosate former powder 42.92g (content 95.5%), former powder yield 78%, total yield 81.3%, get glyphosate mother liquor 78.6g, after this mother liquor adds alkali and reclaims triethylamine, obtains mother liquor to be treated (hereinafter referred to as mother liquor to be treated), then to the mother liquor to be treated Hydrogen chloride gas was passed through the mother liquor to obtain 147.1 g of a solid-liquid mixture, 54.23 g of crude sodium chloride was obtained after suction filtration, and 86.8 g of the mother liquor for acid precipitation and desalination. After chemical composition analysis, the hydrochloric acid content in the acid precipitation and desali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com