Method for reducing scaling between oil field oil extraction transportation system and stratum

A technology for gathering and transportation systems and formations, which is applied in the direction of separation methods, chemical instruments and methods, and grease/oily substances/suspton removal devices, etc., which can solve the problem of reducing scaling between oil production gathering and transportation systems and formations in oil fields, and the large amount of discharged waste water , formation damage and other issues, to achieve the effect of ensuring high-efficiency, continuous and stable production, improving utilization rate, and preventing scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

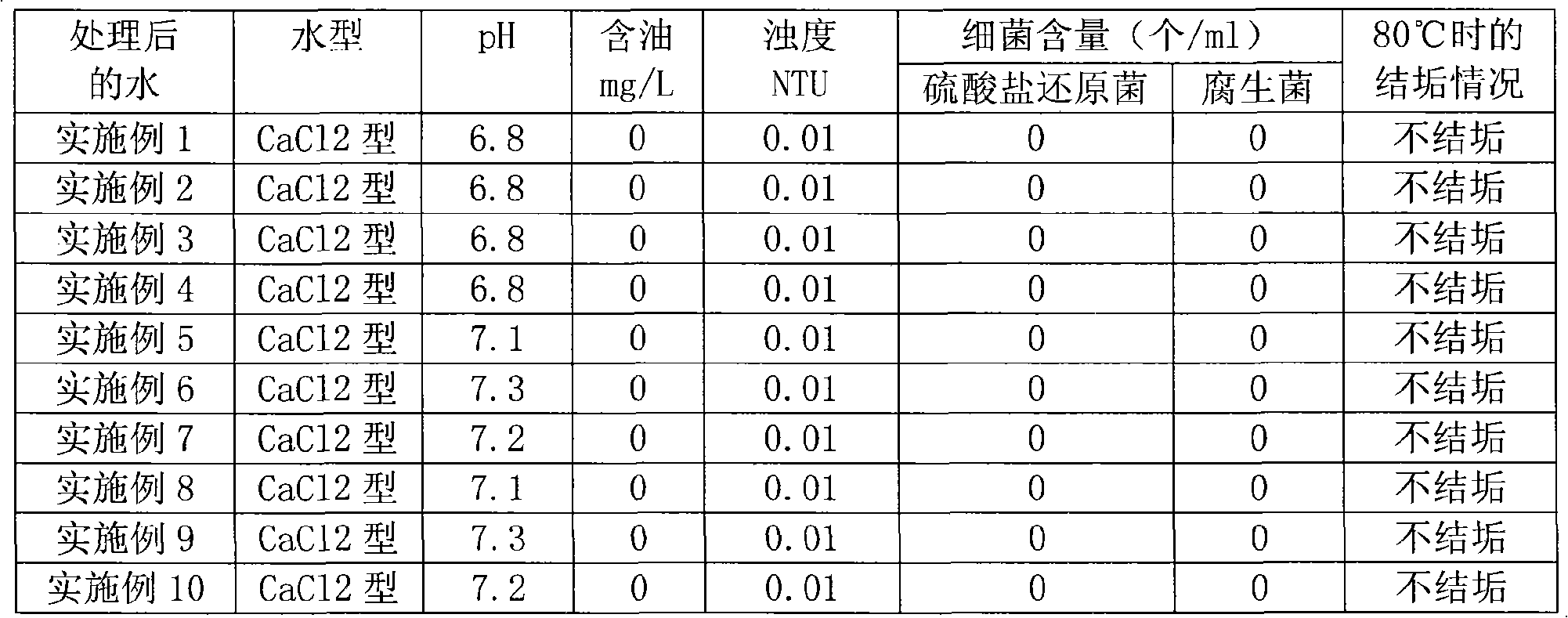

Examples

Embodiment 1

[0028] Embodiment 1, (clear water is seawater, mixes direct water injection)

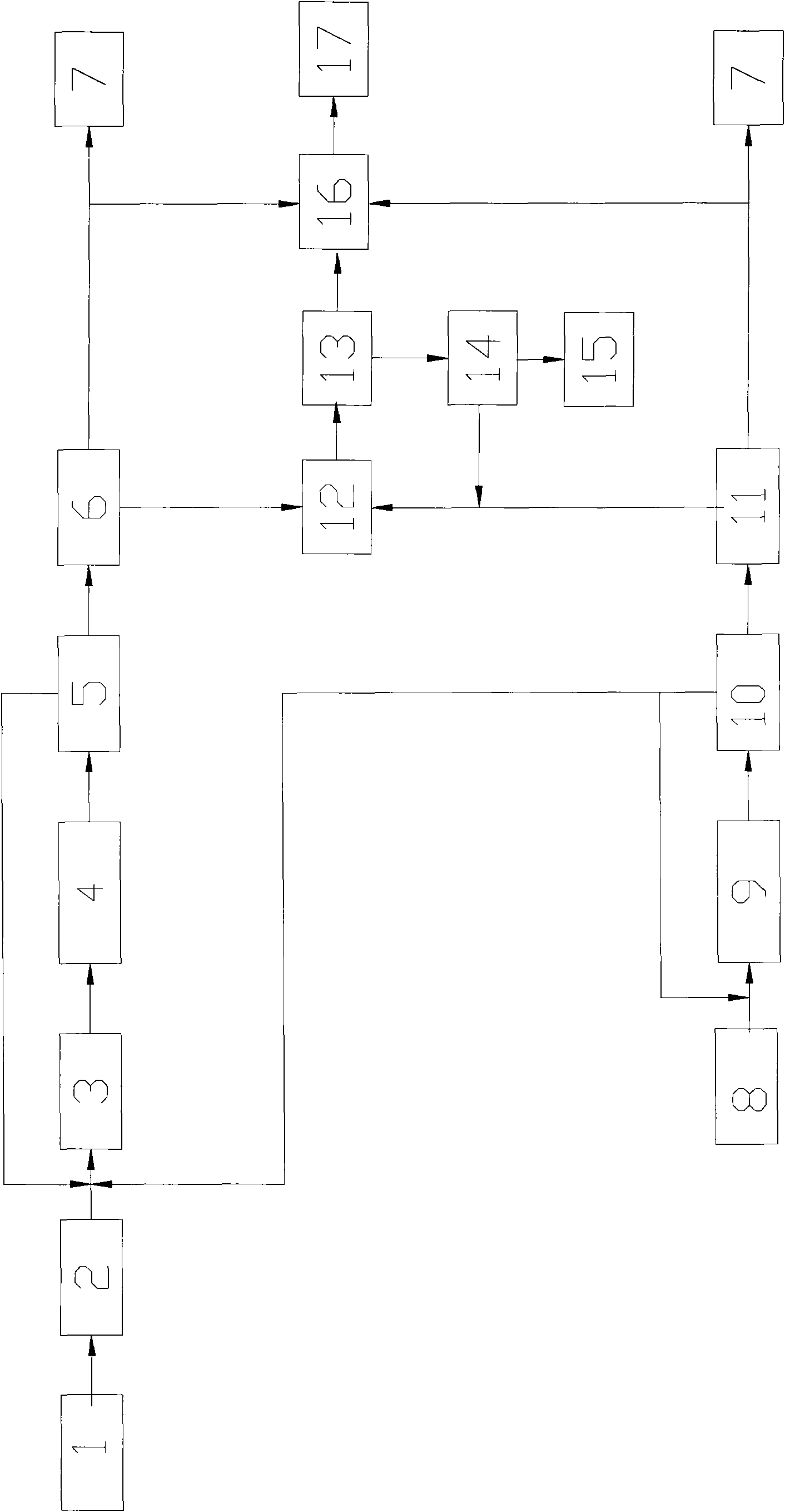

[0029] Its process is as follows figure 1 As shown, the ratio of produced water: clean water is 1:0.5, the water type of produced water is CaCl2 type, and the clean water is seawater.

[0030] In the first step, the produced water 1 passes through the oil separator 2 and the air flotation device 3 to remove suspended oil droplets, partially emulsified oil and dissolved oil, so that the oil content in it is lower than 10mg / L, and then enters the multi-media filter or laminated filter Self-cleaning filter 4 removes solid suspended particles with a particle size of 5 microns or more, and then removes colloids, residual oil, suspended solids, CODcr, polymers, etc. in the water through the dead-end ultrafiltration membrane separation device 5, so that ultrafiltration water The sludge density index (SDI) drops below 3.0, the turbidity is less than 0.1NTU, and the total oil is less than 1mg / L. The ultra-f...

Embodiment 2

[0035] Embodiment 2, (clear water is sea water, mixes and dilutes preparation polymer)

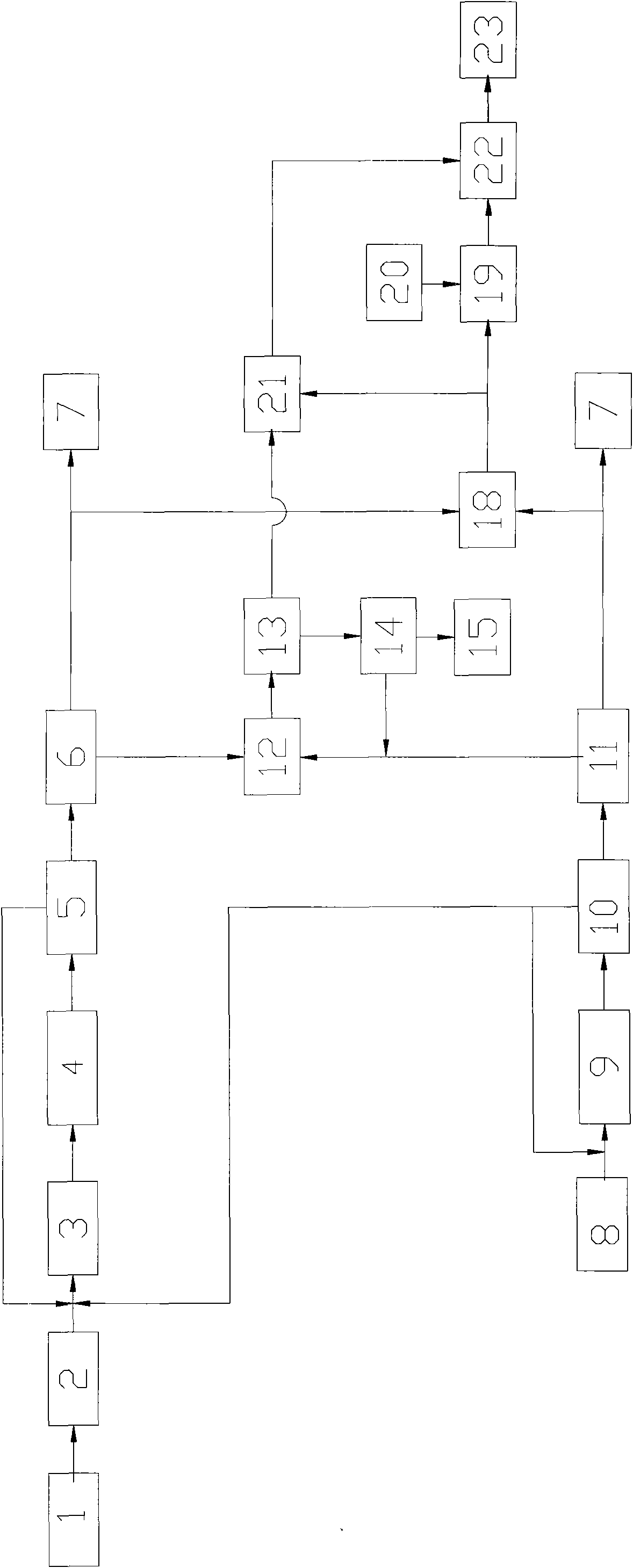

[0036] Its process is as follows figure 2 As shown, the ratio of produced water: clean water is 1:0.5, the water type of produced water is CaCl2 type, and the clean water is seawater.

[0037] According to the first step of embodiment 1, second step operation, wherein, clear water is sea water.

[0038] The average recovery rate of the ultrafiltration of the produced water and the clear water treatment device is 95%, and the recovery rate of the nanofiltration is 60%.

[0039] In the third step, after the nanofiltration demineralized water of the produced water and the nanofiltration demineralized water of the clear water are fully mixed through the static mixer 18, a part of the mixed water enters the polymerization device 19, and a high molecular weight water-soluble water-soluble compound with a molecular weight of 20 million to 45 million is added. Polyacrylamide 20, formulated poly...

Embodiment 3

[0041] Embodiment 3, (clear water is brackish water, mixing direct water injection)

[0042] Its process is as follows figure 1 As shown, the ratio of produced water: clean water is 1:0.6, the water type of produced water is CaCl2 type, and the clean water is brackish water.

[0043] According to the first step of embodiment 1, second step operation, wherein, clear water is brackish water.

[0044] The ultrafiltration recovery rate of produced water and clean water treatment device is 95%, and the recovery rate of nanofiltration is 70%.

[0045] In the third step, the nanofiltration softened water of clean water and the nanofiltration softened water of produced water enter the static mixer 16 and are fully mixed.

[0046] In the fourth step, the nanofiltration concentrated water of the produced water and the nanofiltration concentrated water of the clean water enter the concentrated water static mixer 12 to react and form precipitates, and then enter the self-cleaning filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com