Abrasion resistant material featuring ceramic embedded in metal and preparation method thereof

A wear-resistant material and ceramic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of short life, easy falling off of wear-resistant ceramic blocks, and alternating impact loads, and achieve improved reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Adhesive method to prepare wear-resistant materials embedded with ceramics in metal:

[0035] 1) First prepare the adhesive according to the composition of the following parts by weight: 100 parts of epoxy resin, 20 parts of dibutyl phthalate, 100 parts of alumina powder (300 mesh), 8 parts of ethylenediamine (epoxy resin The preferred grade is E-51 or E-44);

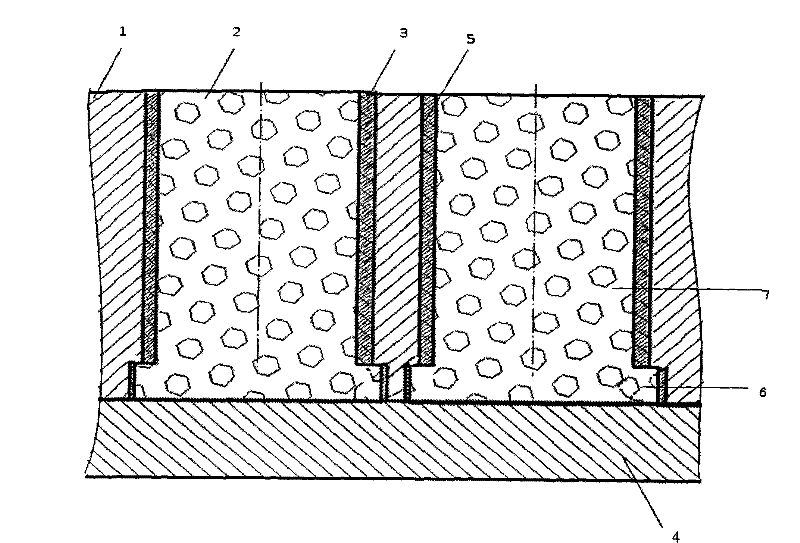

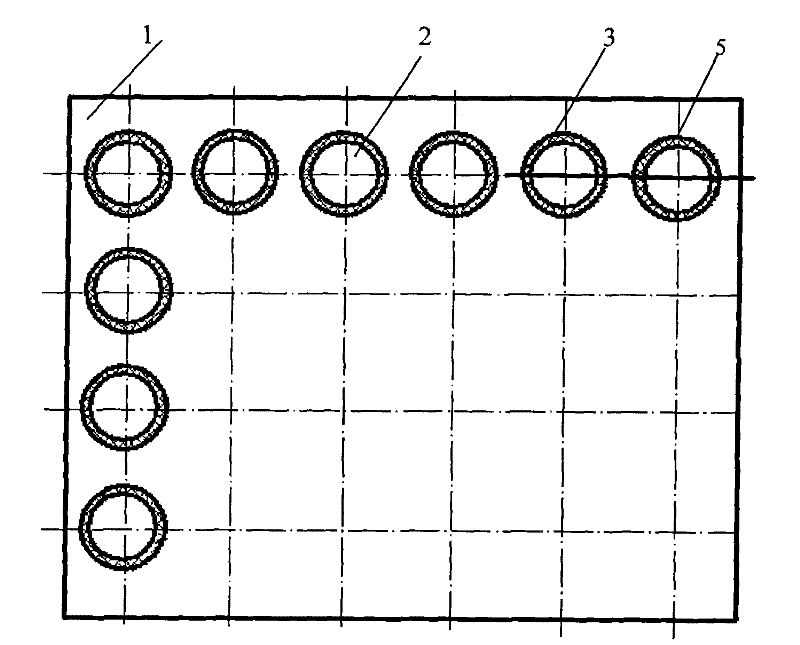

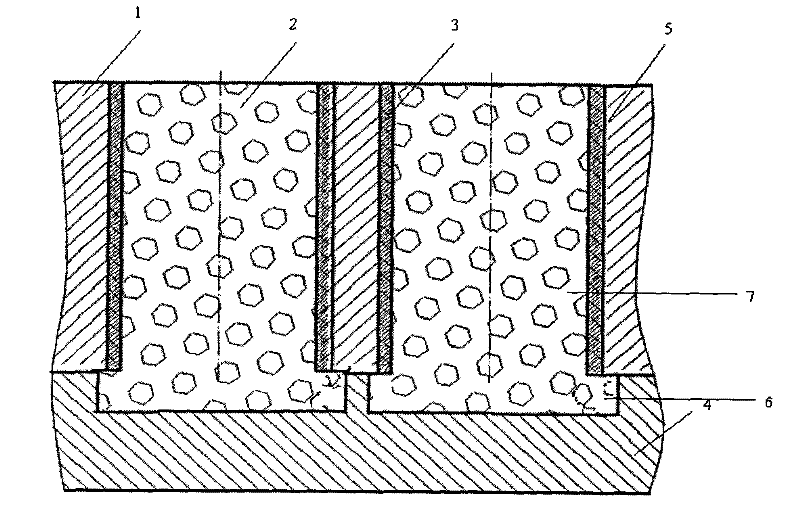

[0036] 2) Apply the adhesive evenly on the surface of the wear-resistant ceramic block, the thickness of the coating is 1.8-2.5mm, and then install the wear-resistant ceramic block in the through hole of the substrate, and make the gap between the through hole and the wear-resistant ceramic block Evenly, after the adhesive is cured, the excess adhesive at the gap between the upper and lower surfaces shall be polished clean (the wear-resistant ceramic block is an alumina ceramic block produced by the existing technology, and the wear-resistant ceramic block is a combination of coaxial cylinders. The diameter of t...

Embodiment 2

[0039] Adhesive method to prepare wear-resistant materials embedded with ceramics in metal:

[0040] 1) First prepare the adhesive according to the following parts by weight: 100 parts of epoxy resin, 20 parts of dibutyl phthalate, 80 parts of alumina powder (300 mesh), 20 parts of silicon powder (300 mesh), 8 parts of diethylenetriamine (the preferred grade of epoxy resin is E-51 or E-44);

[0041] 2) Apply the adhesive evenly in the through hole of the substrate, the thickness of the coating is 1.5-2.0mm, and then install the wear-resistant ceramic block in the through hole of the substrate, and make the gap between the through hole and the wear-resistant ceramic block Evenly, after the adhesive is cured, the excess adhesive at the gap between the upper and lower surfaces shall be polished clean (the wear-resistant ceramic block is an alumina ceramic block produced by the existing technology, and the wear-resistant ceramic block is a combination of coaxial cylinders. The di...

Embodiment 3

[0044] Preparation of wear-resistant materials inlaid with ceramics in metals by hot charging:

[0045] 1) Heat the substrate with through holes to 120°C in the furnace. After the diameter of the through hole on the substrate becomes larger due to expansion, immediately install the wear-resistant ceramic block into the through hole. After cooling, the through hole shrinks, and the wear-resistant The ceramic block is firmly fixed in the through hole (the wear-resistant ceramic block is an alumina ceramic block produced by the prior art, the wear-resistant ceramic block is a combination of coaxial cylinders, the diameter of the working section is 8mm, the height is 8mm, The diameter of the positioning section is 10mm and the height is 3mm; 8mm thick low-carbon steel is selected as the substrate 1, the length and width of the substrate 1 are 166mm and 86mm respectively, and 10×5 through holes with a diameter of 7.9mm are opened on the substrate 1 , the through holes are evenly di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com