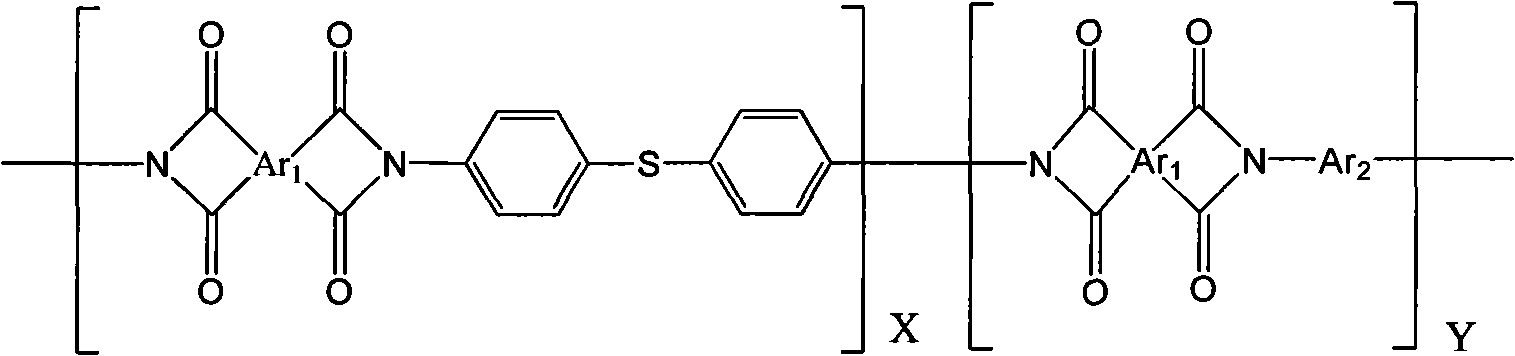

Polyimide copper clad lamination containing thioether structure and preparation method thereof

A technology of polyimide and polyimide layer, applied in chemical instruments and methods, circuit substrate materials, improvement of metal adhesion of insulating substrates, etc., can solve problems such as poor bonding performance and low thermal expansion coefficient, and achieve Excellent film-forming properties, low thermal expansion coefficient, and excellent dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

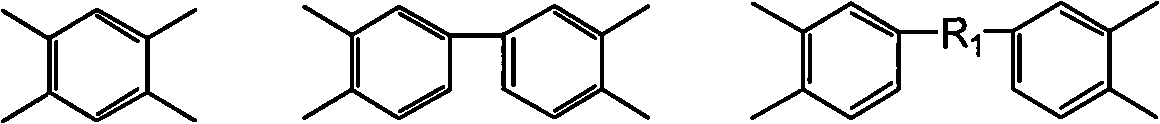

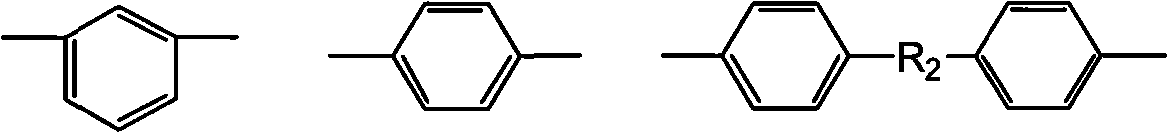

Method used

Image

Examples

Embodiment 1

[0042]In a 100mL three-necked flask equipped with electromagnetic stirring, a thermometer and an inert gas protection device, add 2.180g (10.0mmol) 4,4'-diaminodiphenyl sulfide, add 27mL N,N-dimethylformamide, Dissolve the diamine. Then drop into 3.2039g (9.95mmol) 3 in batches, 3 ', 4, the 4-benzophenone tetraacid dianhydride, add time interval more than 10 minutes each time, guarantee its sufficient reaction. After the addition, start timing, stir and react at room temperature for 4.5 hours, stop stirring, and obtain the corresponding polyamic acid solution.

[0043] Coat the amic acid solution evenly on a clean copper foil, then place it in a high-temperature vacuum oven, and carry out thermal imidization reaction with gradient temperature rise. , heating up for 0.3h)→190°C (0.15h of heat preservation, 0.3h of temperature rise)→240°C (0.15h of heat preservation, 0.3h of temperature rise)→320°C (0.3h of heat preservation). After the reaction is finished, a polyimide copper...

Embodiment 2

[0045] The polyamic acid solution in Example 1 is evenly coated on the copper foil respectively to control a certain wet film thickness, then the coated surfaces of the two coated copper foils are stacked and placed in a high-temperature vacuum oven In, the thermal imidization reaction was carried out according to the gradient temperature raising conditions described in Example 1. After the reaction is finished, a double-sided polyimide copper-clad laminate is obtained.

Embodiment 3

[0047] Use the mixed diamine of 3.0mmol 4,4`-diaminodiphenyl sulfide and 7.0mmol 4,4`-diaminodiphenyl ether to replace 10.0mmol of 4,4`-diaminodiphenyl sulfide in Example 1 , the reaction time was 5 hours, and other implementation methods were the same as in Example 1. The initial decomposition temperature of the obtained polymer under a nitrogen atmosphere is greater than 480°C; the glass transition temperature measured by DMA is 295.3°C, the peel strength with copper foil is 1.037kgf / cm, and the number of flexures of the copper clad laminate is 117 times (0.5 kgf; 0.38R).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Onset decomposition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap