Non-chromium pretreating agent for color coated steel plate

A color-coated steel plate and pretreatment agent technology, which is applied in the coating process of metal materials, can solve problems such as serious harm to the human body and the environment, and achieve the effects of improving corrosion resistance, preventing intrusion, and improving precision and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

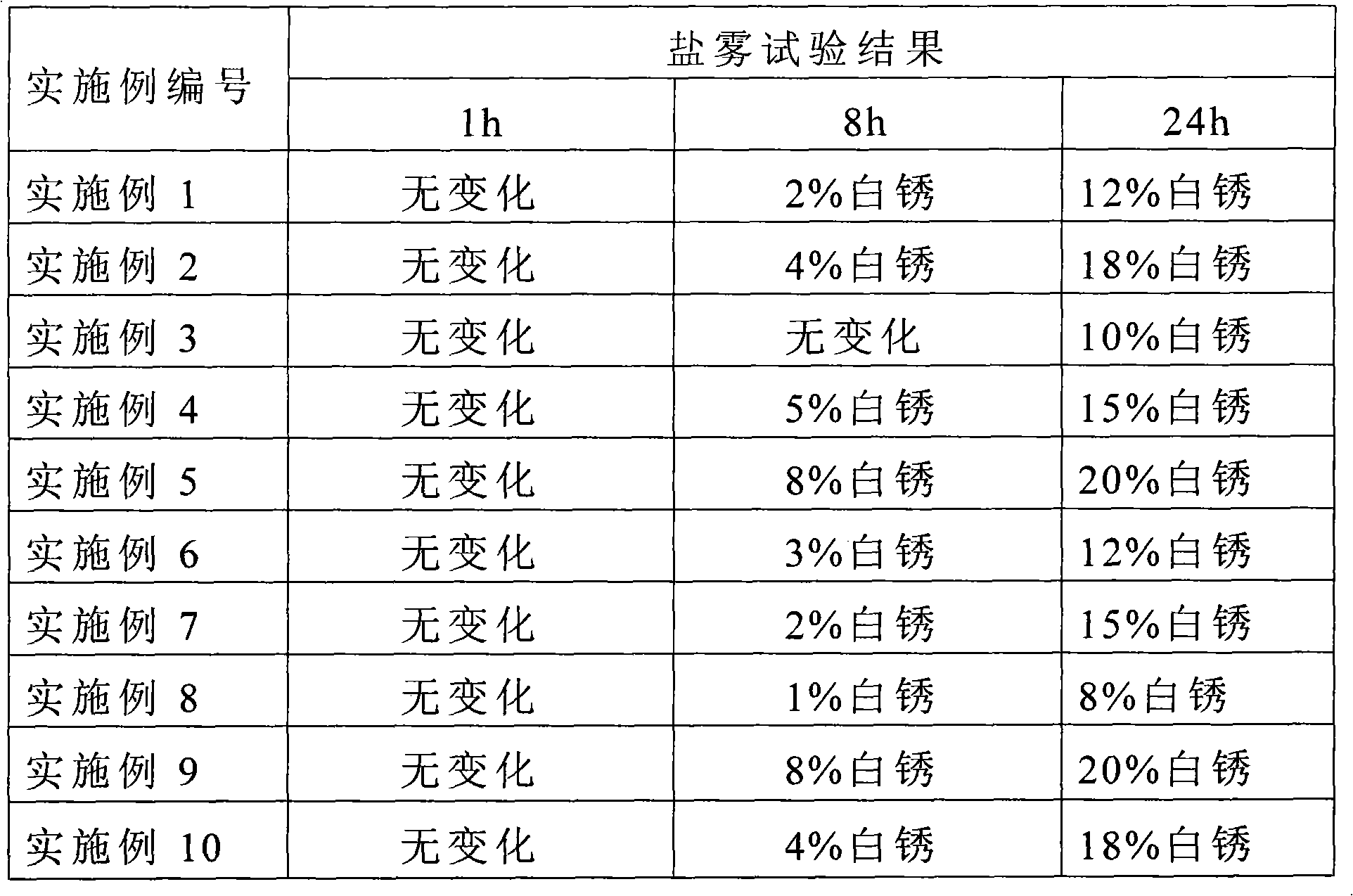

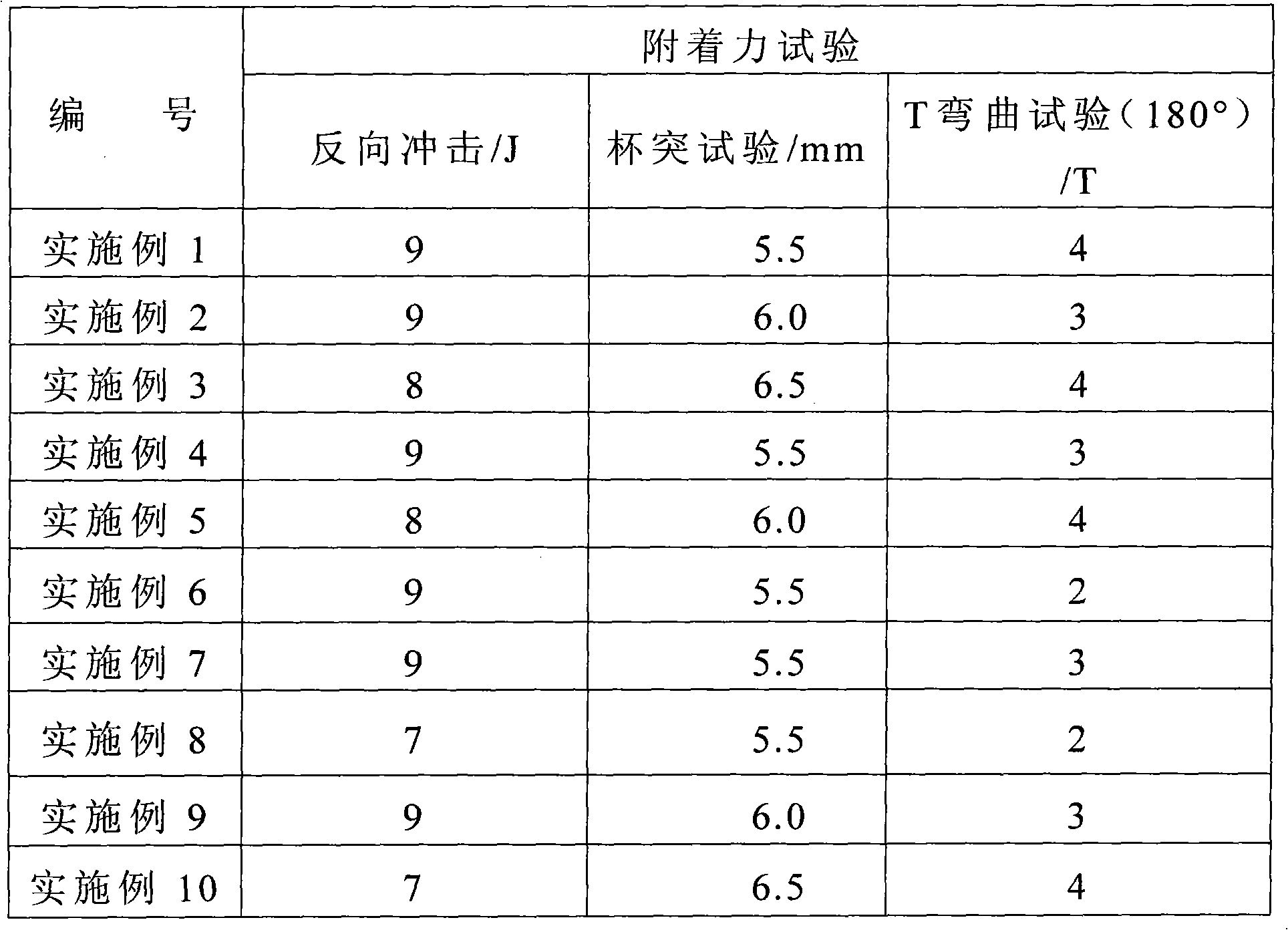

Examples

Embodiment 1

[0023] Example 1: 3g polyacrylic acid, 1g sodium molybdate, 1g sodium chlorate, 1g sodium fluoride, 1g fluorotitanic acid, 1g titanium trichloride, 1g zinc phosphate, 3g sodium hexametaphosphate, 1g sodium dihydrogen phosphate Dissolve in 100 g deionized water and stir to form a solution.

Embodiment 2

[0024] Embodiment 2: with 3g phytic acid, 1g polyacrylic acid, 1g sodium molybdate, 1g sodium chlorate, 1g sodium fluoride, 1g fluotitanic acid, 1g titanium trichloride, 2g zinc phosphate, 3g sodium hexametaphosphate, 1g Dissolve sodium dihydrogen phosphate in 100 g of deionized water, and stir to form a solution.

Embodiment 3

[0025] Embodiment 3: with 1.5g phytic acid, 1.5g polyacrylic acid, 1g sodium molybdate, 1g sodium chlorate, 1g sodium fluoride, 1g fluotitanic acid, 1g titanium trichloride, 2g zinc phosphate, 3g sodium hexametaphosphate , Dissolve 1g of sodium dihydrogen phosphate in 100g of deionized water, and stir to form a solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com