Preparation method of negative electrode material of lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve problems such as electrode preparation methods are not considered, achieve stable cycle performance, clean industrial production, and realize the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 0.5 grams of flake graphite with an average particle size of 30 microns, 0.4 grams of sodium nitrate and 2.5 grams of potassium permanganate were added to 20 grams of concentrated sulfuric acid with a mass fraction of 98%, stirred for 120 hours, filtered and washed, and placed in 20 In an aqueous solution, ultrasonically disperse at a frequency of 40KHz and a power of 200W for 2 hours, add 0.1 gram of hydrazine hydrate, stir at room temperature for 12 hours, perform vacuum filtration under a vacuum of 20.0KPa, and dry naturally to obtain a lithium-ion battery Negative material.

[0024] figure 1 It is a digital photo of the lithium ion battery negative electrode material prepared by Example 1. Depend on figure 1 It can be seen that the area of the graphene film obtained in Example 1 is 1 square centimeter.

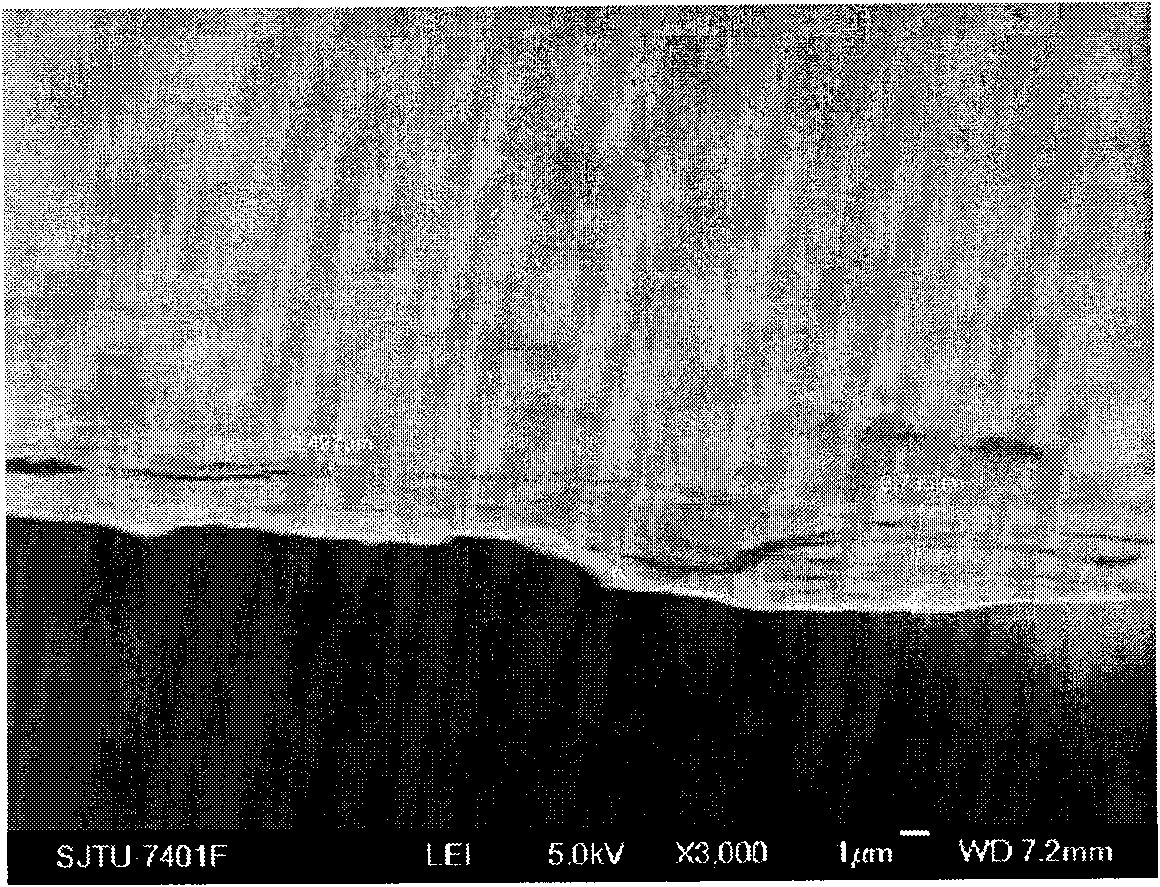

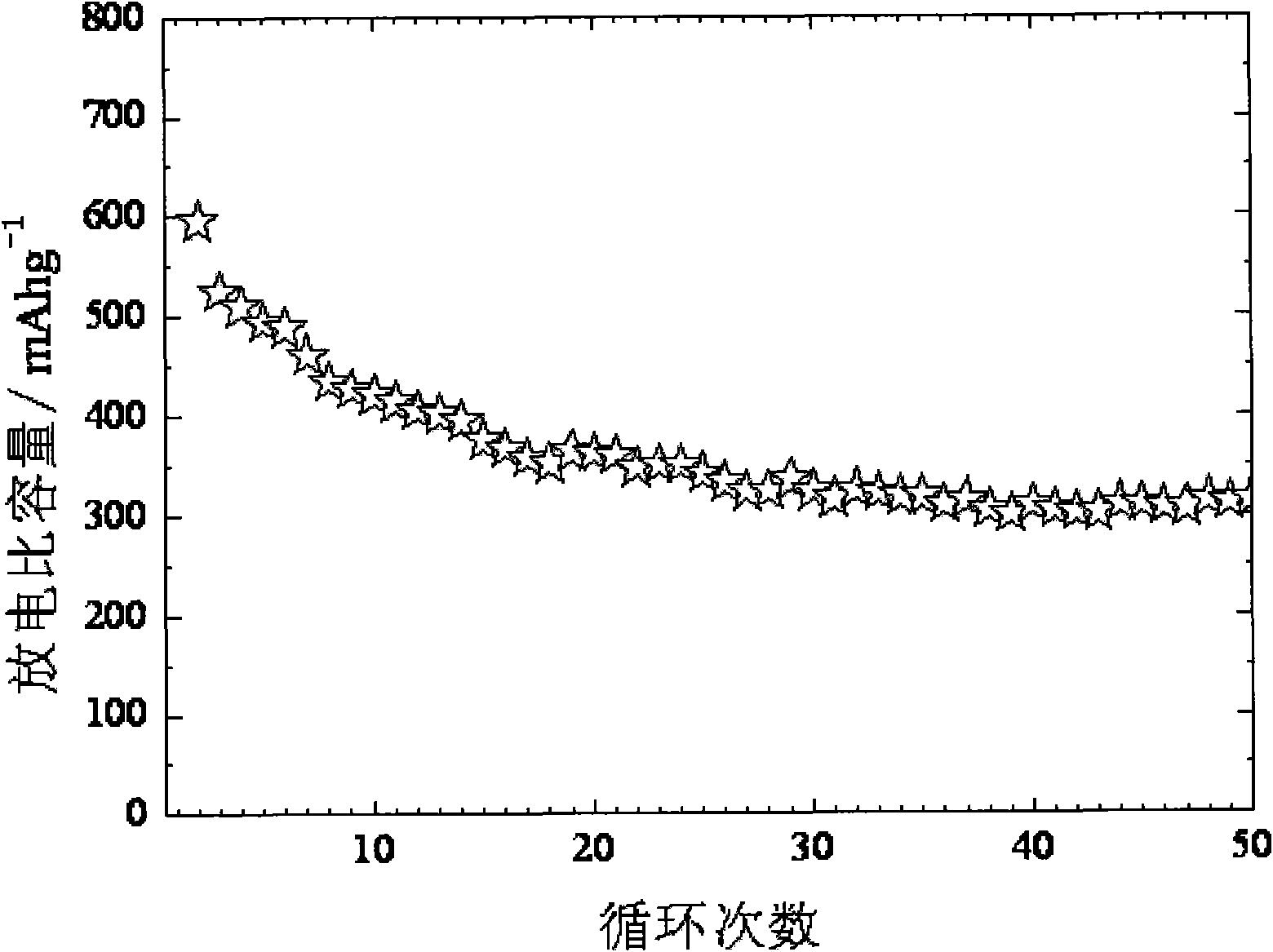

[0025] figure 2 It is the scanning electron microscope picture of the negative electrode material of lithium ion battery prepared by example 1. Depend on ...

Embodiment 2

[0029] 1.0 grams of flake graphite with an average particle size of 30 microns, 0.8 grams of sodium nitrate and 5.0 grams of potassium permanganate were added to 40 grams of concentrated sulfuric acid with a mass fraction of 98%, stirred for 120 hours, filtered and washed, and placed in 40 In an aqueous solution, disperse ultrasonically for 2 hours at a frequency of 40KHz and a power of 200W, add 0.2 gram of hydrazine hydrate, stir at room temperature for 12 hours, perform vacuum filtration under a vacuum of 20.0KPa, and dry naturally to obtain a lithium ion battery Negative material. The obtained graphene film has an area of 1 square centimeter and a thickness of about 6 microns, and the -1 The reversible specific capacity of the current charge and discharge test is 250mAh·g -1 .

Embodiment 3

[0031] 5.0 grams of flake graphite with an average particle size of 30 microns, 4.0 grams of sodium nitrate and 25 grams of potassium permanganate were added to 200 grams of concentrated sulfuric acid with a mass fraction of 98%, stirred for 100 hours, filtered and washed, and placed in 200 In an aqueous solution, disperse ultrasonically for 2 hours at a frequency of 40KHz and a power of 200W, add 1 gram of hydrazine hydrate, stir at room temperature for 12 hours, perform vacuum filtration under a vacuum of 20.0KPa, and dry naturally to obtain a lithium-ion battery Negative material. The obtained graphene film has an area of 4 square centimeters and a thickness of about 6 microns, and the -1 The reversible specific capacity of the current charge and discharge test is 200mAh·g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com