Method for preparing biodiesel with no byproduct glycerol

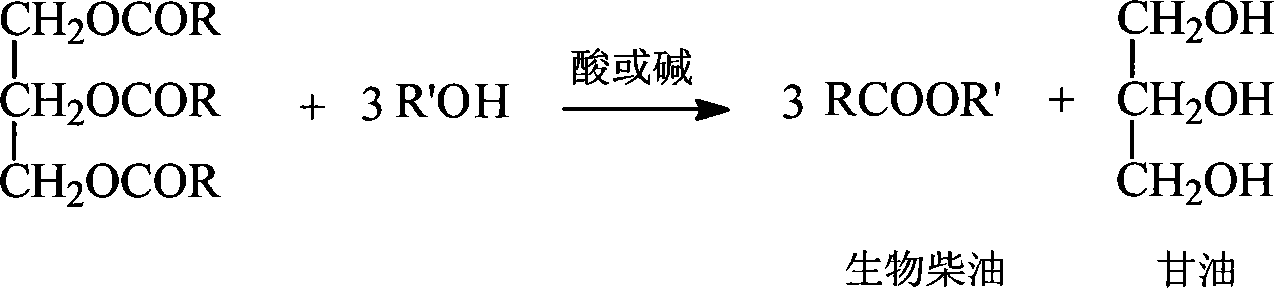

A biodiesel and glycerol technology, applied in renewable new energy and green fields, can solve problems such as inability to fundamentally solve glycerol, excess, and inability to fundamentally solve catalyst waste water pollution, so as to solve technical and economic burdens and avoid pollution. , the effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

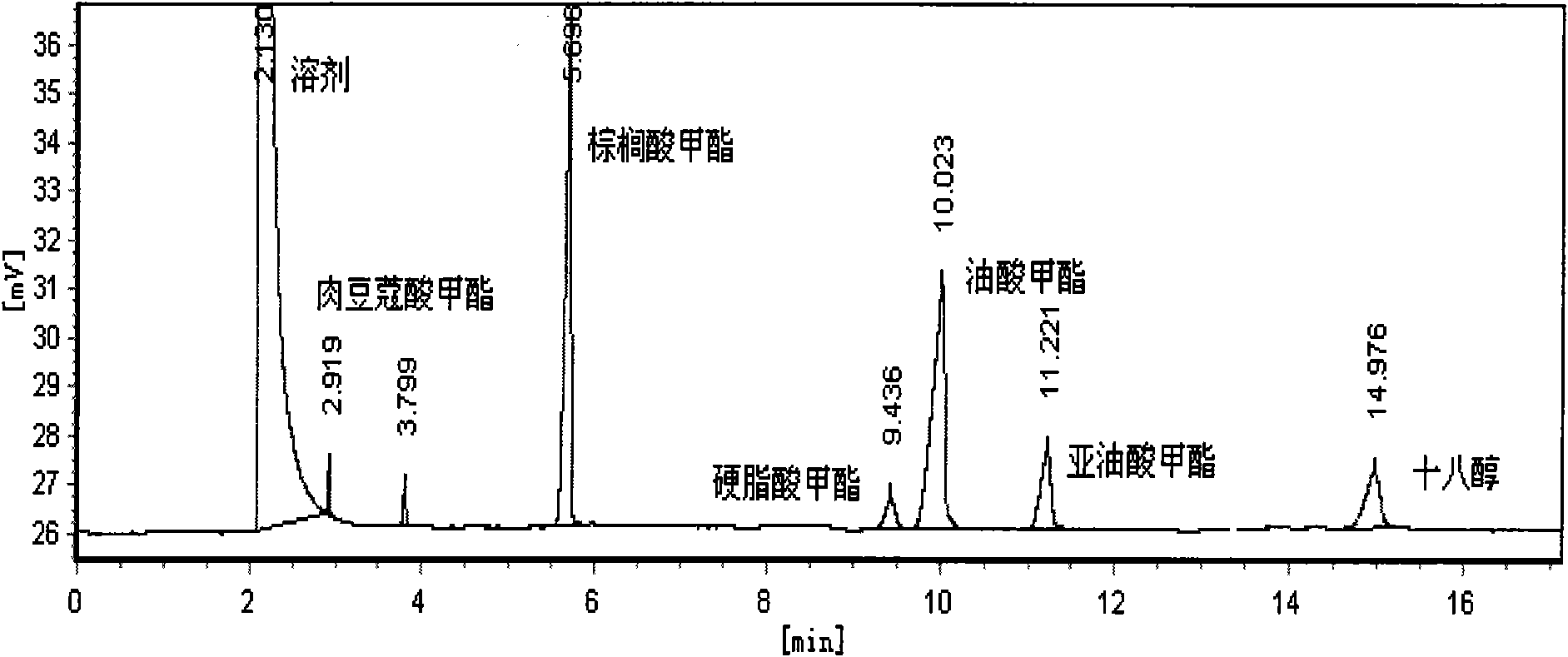

[0042] Add 43g (0.05mol) of palm oil into a four-necked flask filled with 67.5g of dimethyl carbonate (0.75mol) and heat up to 90°C, then add 3.9g of sodium methylate into it, stir and react for 6 hours, and remove the catalyst by suction filtration. Rotary evaporation decompression removes excess dimethyl carbonate, leaves standstill without the appearance of glycerin stratification, utilizes gas chromatography to carry out quantitative analysis to product, as figure 1 As shown, no glycerol was detected, and the yield of fatty acid methyl ester active ingredient reached 88.5%.

Embodiment 2

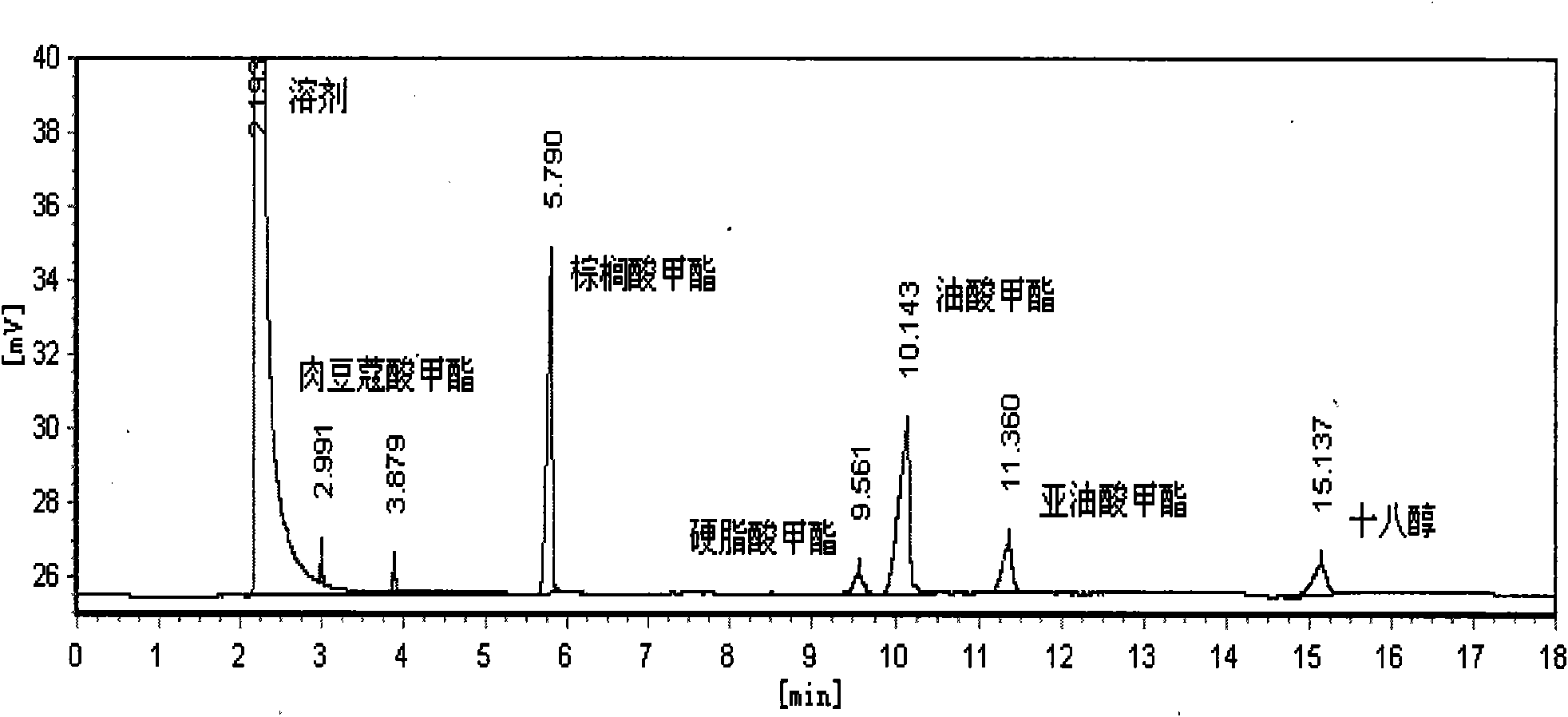

[0044] After adding 43g (0.05mol) of palm oil into a four-necked flask filled with 85.5g of diethyl carbonate (0.75mol), the temperature was raised to 125°C, and 3.9g of organic base 1,5,7-triazabicyclo[4, 4,0] decan-5-ene (TBD) was added therein, and after stirring for 8 hours, the catalyst was removed, the excess diethyl carbonate was removed by rotary evaporation under reduced pressure, and no glycerol stratification appeared on standing, and the product was quantified by gas chromatography Analysis showed that glycerol was not detected, and the yield of fatty acid methyl ester active ingredient reached 73.2%.

Embodiment 3

[0046] After adding 43g (0.05mol) of palm oil into a four-neck flask filled with 94.5g of dimethyl sulfate (0.75mol), the temperature was raised to 190°C, and 3.9g of Al 2 o 3 -SiO 2 Add it, stir and react for 7 hours, remove the catalyst, remove the excess dimethyl sulfate by rotary evaporation under reduced pressure, and leave it to stand without glycerin stratification. The product is quantitatively analyzed by gas chromatography, and no glycerin and fatty acid methyl esters are detected. The yield reached 82.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com