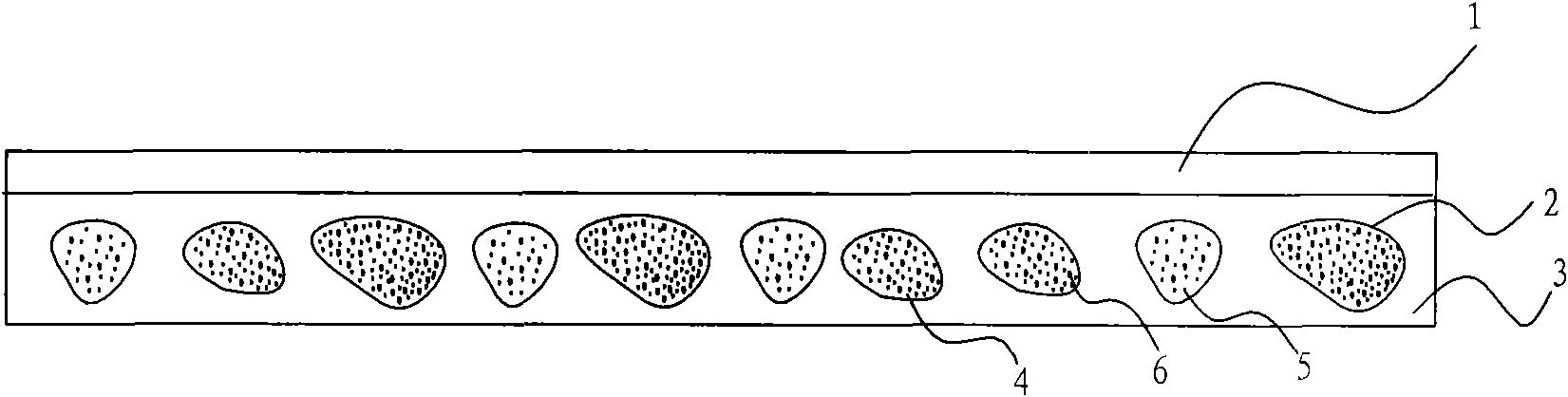

Bistable magnetic display panel and manufacturing method thereof

A manufacturing method and display panel technology, applied to reusable writing boards, printing, instruments, etc., can solve the problems of limiting the application range of magnetic display panels, reducing display resolution, and low packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

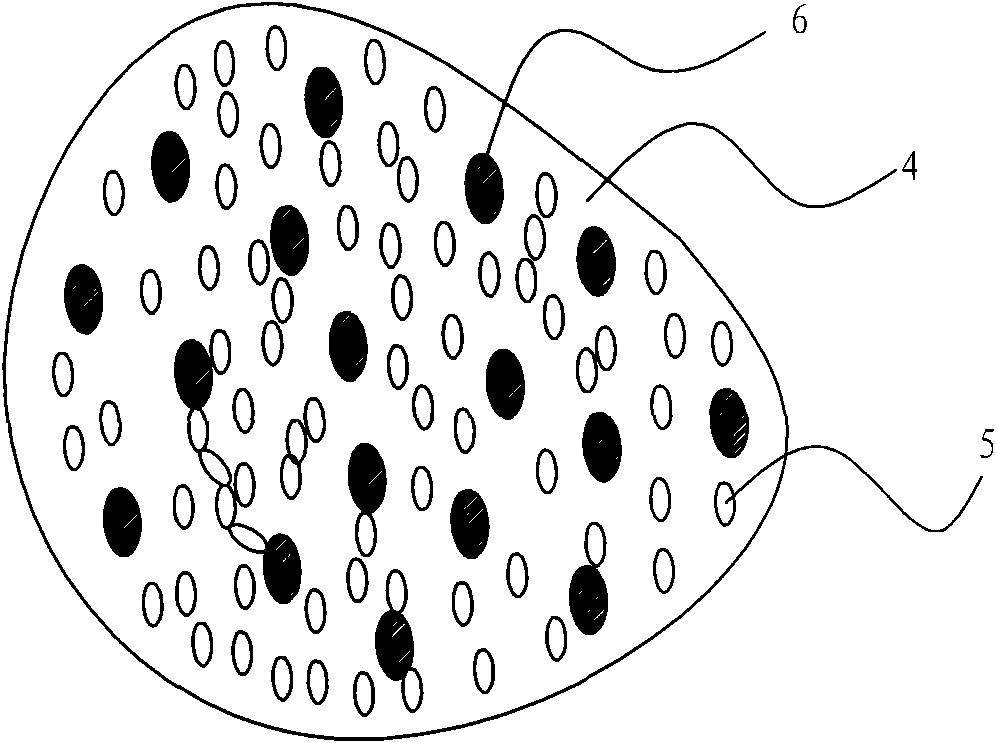

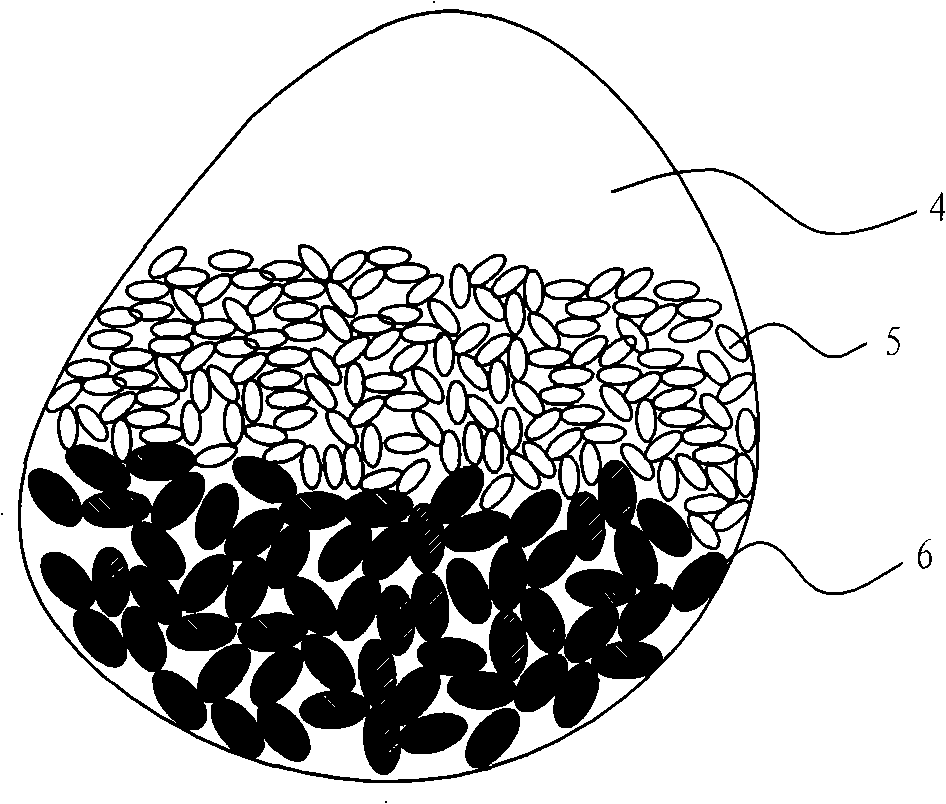

[0039] Add 0.2g of sodium lactate into 30g of ethylene glycol and stir to dissolve, then add 4.0g of Fe 3 o 4 Stir and disperse for 30 minutes to obtain mixture A, 10gTiO 2 Add 20 g of ethylene glycol and stir to disperse for 30 minutes, then add 0.1 g of a 30% aqueous solution of sodium polyacrylate with an average molecular weight of 8,000, continue to stir and disperse for 30 minutes to obtain mixture B, mix mixture A and mixture B for 10 minutes to obtain mixture C, and Add 0.8 g of diethylenetriamine to mixture C and stir to obtain mixture D. Add 20g of chlorinated polypropylene into 80g of xylene and stir until completely dissolved to obtain mixture E, add 30g of mixture D into mixture E and slowly stir until the average diameter of dispersed droplets is 80 microns, start to drop 50% xylene solution of toluene diisocyanate 1g, added dropwise within 20 seconds, after 10 minutes of reaction, keep the stirring speed constant, slowly add the remaining mixture D to the mixt...

Embodiment 2

[0045] Add 0.3g of sodium citrate into the mixed dispersion of 15g of ethylene glycol and 15g of deionized water and stir to dissolve, then add 3g of Fe 3 o 4 Stir and disperse for 30 minutes to obtain mixture A, 8.0g TiO 2Add 10 g of ethylene glycol and 10 g of deionized water to the mixed dispersion and stir for 30 minutes to disperse, then add 0.2 g of an aqueous solution of 20% acrylic acid-methyl acrylate copolymer sodium salt (acrylic acid content 40%) with an average molecular weight of 32,000, and continue to stir and disperse for 30 minutes To obtain mixture B, mix mixture A and mixture B and stir for 10 minutes to obtain mixture C, add 0.4 g of triethylenetetramine to mixture C and stir to obtain mixture D. Add 20g of methyl methacrylate-butyl acrylate copolymer into 80g of xylene and stir until completely dissolved to obtain mixture E, add 30g of mixture D into mixture E and slowly stir until the average diameter of dispersed droplets is 100 microns, and start to a...

Embodiment 4

[0049] Add 0.3g of sodium citrate into the mixed dispersion of 15g of ethylene glycol and 15g of deionized water and stir to dissolve, then add 3g of Fe 3 o 4 Stir and disperse for 30 minutes to obtain mixture A, 8.0g TiO 2 Add 10 g of ethylene glycol and 10 g of deionized water to the mixed dispersion and stir for 30 minutes to disperse, then add 0.2 g of an aqueous solution of 20% acrylic acid-methyl acrylate copolymer sodium salt (acrylic acid content 40%) with an average molecular weight of 32,000, and continue to stir and disperse for 30 minutes To obtain mixture B, mix mixture A and mixture B and stir for 10 minutes to obtain mixture C, add 0.4 g of triethylenetetramine to mixture C and stir to obtain mixture D. Add 20g of methyl methacrylate-butyl acrylate copolymer into 80g of xylene and stir until completely dissolved to obtain mixture E, add 10g of mixture D into mixture E and slowly stir until the average diameter of dispersed droplets is 100 microns, and the rest ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com