Preparation method of 2-hydroxypropyltrimethyl ammonium chloride chitosan

A technology of hydroxypropyltrimethylammonium chloride and chitosan, which is applied in the preparation of chitosan quaternary ammonium salt, the field of preparation of 2-hydroxypropyltrimethylammonium chloride chitosan, can solve the problem of chitosan Difficult to meet the performance of polysan quaternization products, increase the cost of chemical modification, reduce chitosan grafting efficiency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

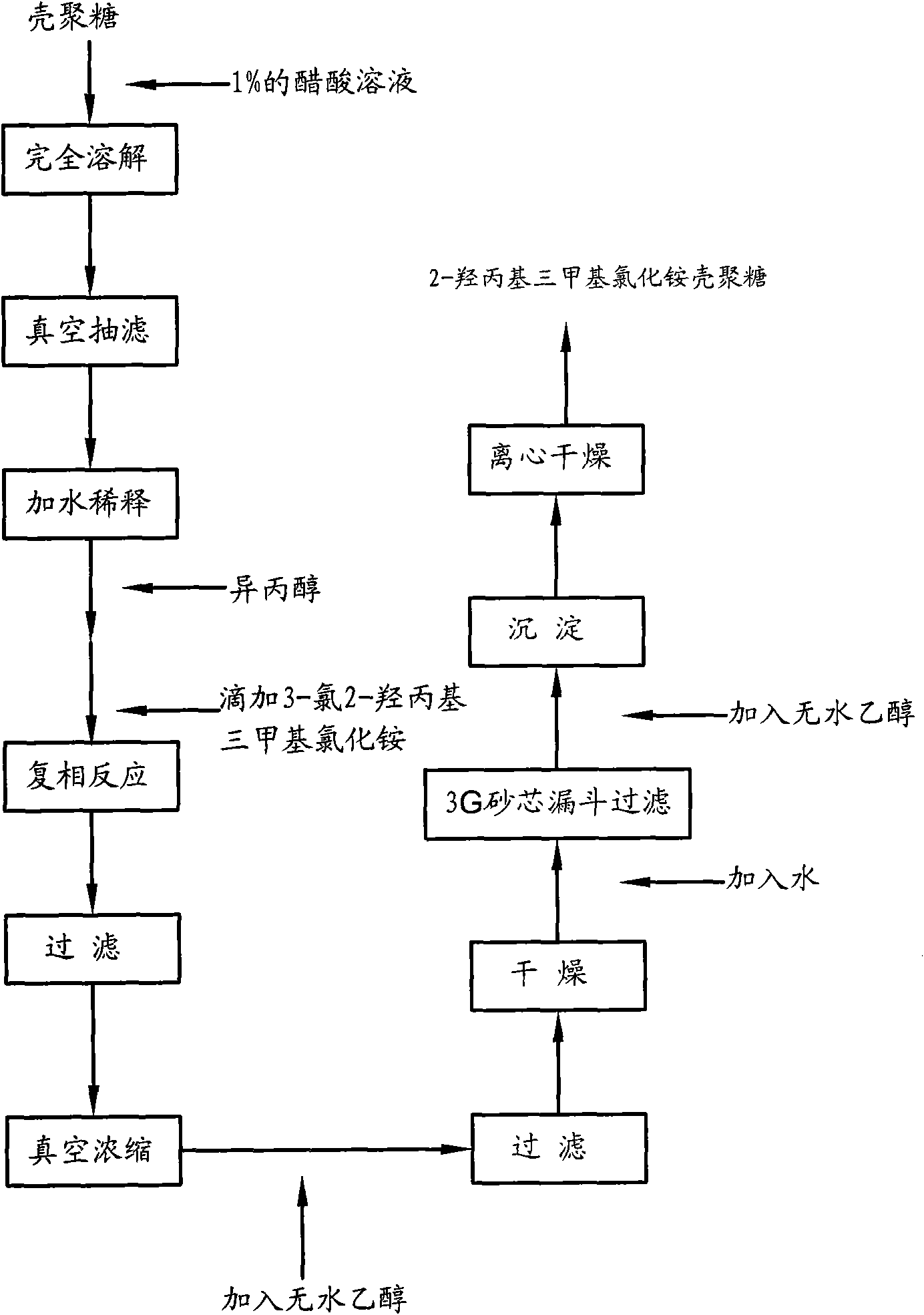

Method used

Image

Examples

Embodiment 1

[0052] Chitosan was added to a NaOH solution with a mass fraction of 20%, and the reaction was stirred for 15 hours at a temperature of 110° C. and a pressure of 0.2 Mpa. The supernatant was poured off, and washed with deionized water until neutral. A chitosan with a degree of deacetylation of 90% is obtained.

[0053] Dissolve 5g of chitosan with a deacetylation degree of 90% in an acetic acid solution with a mass fraction of 1%, soak in a water bath at a temperature of 60°C for 5 hours to completely dissolve, vacuum filter, filter out insoluble matter, and add deionized water 40ml of diluted filtrate was poured into a three-necked flask, stirred for 30 minutes, then 80ml of isopropanol was added to separate out chitosan, and 20g of 3-chloro-2-hydroxypropyltrimethylammonium chloride was made into a solution and added in three times. Add once every 2 hours, and each titration time is controlled within half an hour for complex reaction. The reaction temperature is 80°C, and th...

Embodiment 2

[0055] Chitosan was added to NaOH solution with a mass fraction of 20%, and the reaction was stirred for 10 hours at a temperature of 120°C and a pressure of 0.4Mpa, and the supernatant liquid was poured off, washed with deionized water until neutral. A chitosan with a degree of deacetylation of 95% is obtained.

[0056] Dissolve 10g of chitosan with a deacetylation degree of 95% in an acetic acid solution with a mass fraction of 1%, soak in a water bath at a temperature of 60°C for 8 hours to completely dissolve, vacuum filter, filter out insoluble matter, and add deionized water 40ml of diluted filtrate was poured into a three-necked flask, stirred for 30 minutes, then 80ml of isopropanol was added to separate out chitosan, and 50g of 3-chloro-2-hydroxypropyltrimethylammonium chloride was made into a solution and added in three times. Add once every 2 hours, and each titration time is controlled within half an hour for complex reaction. The reaction temperature is 80°C, and...

Embodiment 3

[0058] Chitosan was added to a NaOH solution with a mass fraction of 20%, and the reaction was stirred for 6 hours at a temperature of 115°C and a pressure of 0.3Mpa, and the supernatant liquid was poured off, washed with deionized water until neutral. A chitosan with a degree of deacetylation of 95% is obtained.

[0059] Dissolve 12g of chitosan with a deacetylation degree of 95% in an acetic acid solution with a mass fraction of 1%, soak in a water bath at a temperature of 60°C for 10 hours to completely dissolve, vacuum filter, filter out insoluble matter, and add deionized water 40ml of diluted filtrate was poured into a three-necked flask, stirred for 30 minutes, then 80ml of isopropanol was added to separate out chitosan, and 72g of 3-chloro-2-hydroxypropyltrimethylammonium chloride was made into a solution and added in three times. Add once every 2 hours, and each titration time is controlled within half an hour for complex reaction. The reaction temperature is 80°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com