Polyvinyl alcohol/inorganic nanometer oxide particle composite material and preparation method thereof

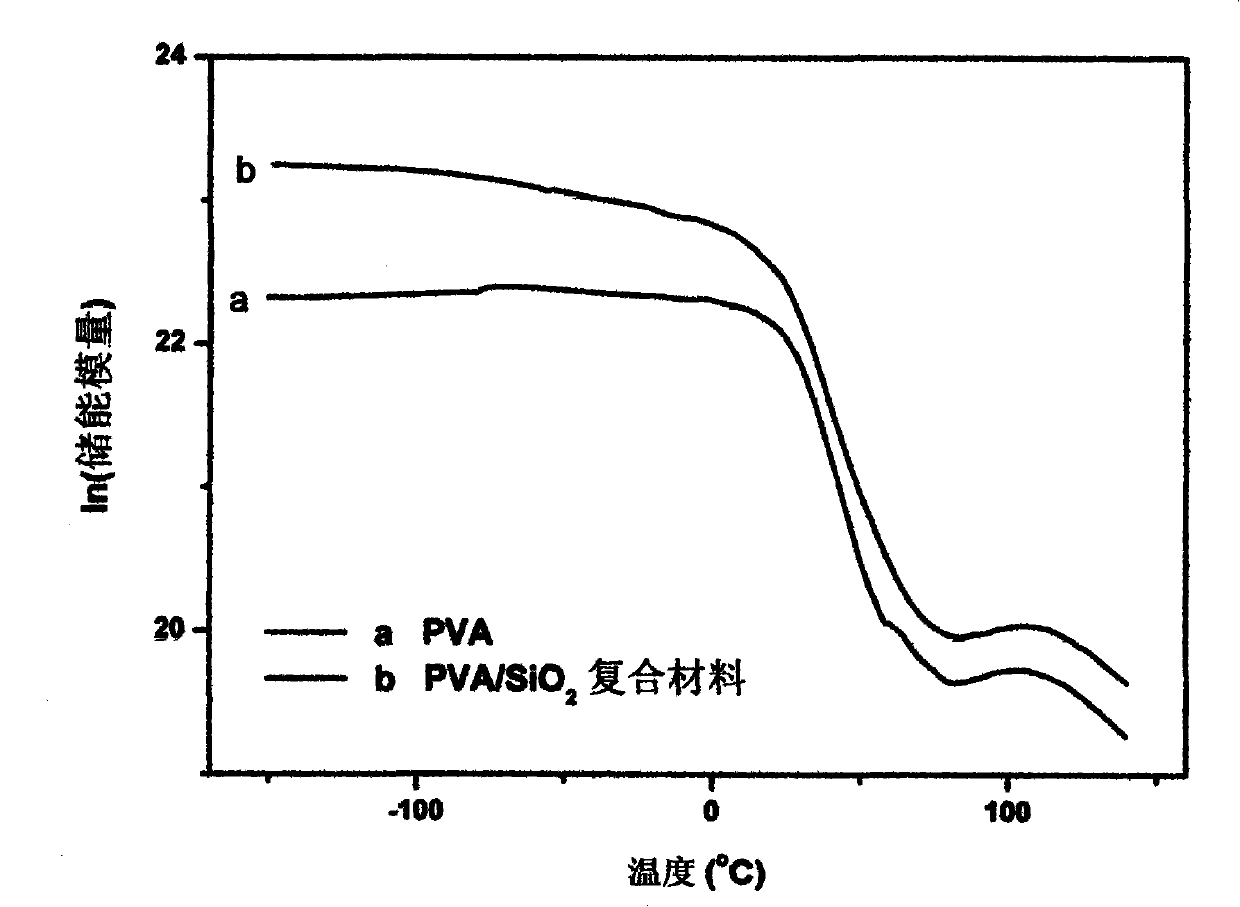

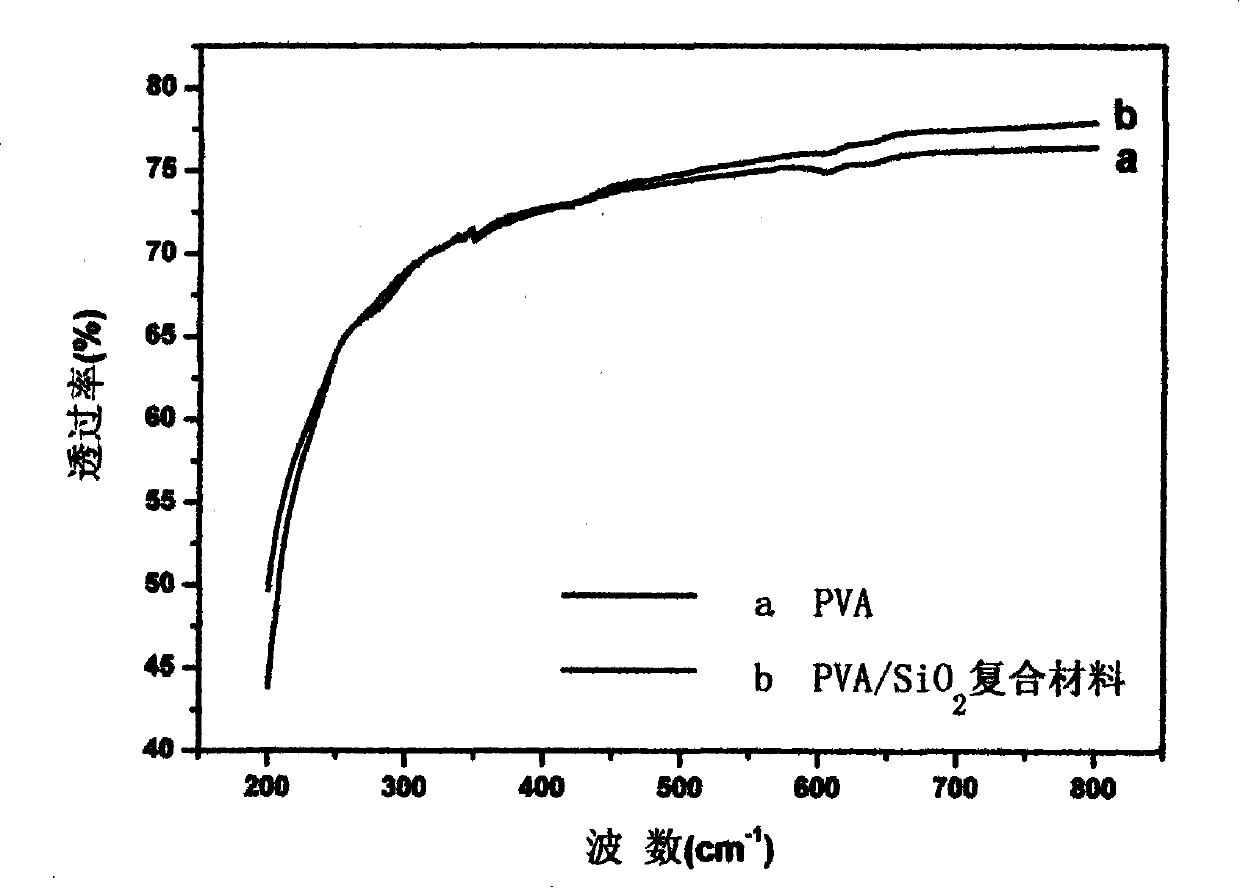

An inorganic nano and polyvinyl alcohol technology, applied in the field of polyvinyl alcohol/inorganic nano oxide particle composite material and its preparation, can solve the problem that the strength and thermal decomposition temperature are not substantially improved, there is no strong chemical bonding effect, The problem of limited influence of material properties, etc., can achieve the effect of improving thermal stability, storage modulus, and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

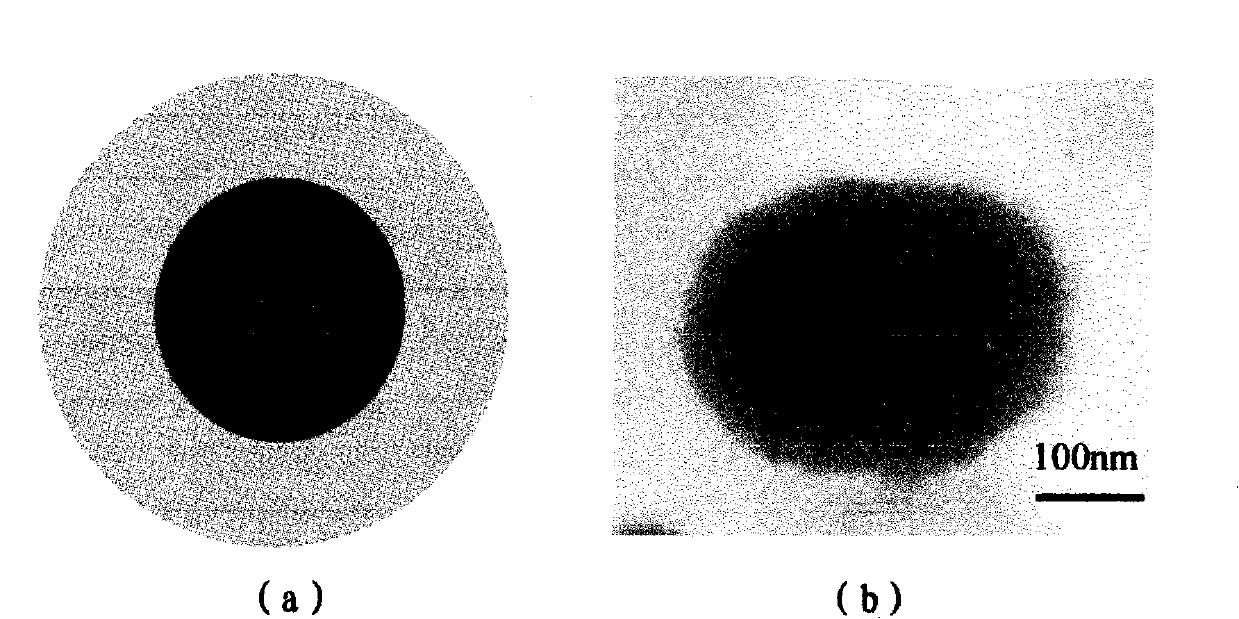

[0022]The specific steps of preparation are: step 1, disperse the inorganic nano-oxide particles into low-molecular-weight alcohol to obtain a dispersion of inorganic nano-oxide particles, or use the sol-gel method to obtain a low-molecular-weight alcohol sol of inorganic nano-oxide particles ; Wherein, the weight ratio between the inorganic nano oxide particle and the low molecular alcohol in the low molecular alcohol sol of the inorganic nano oxide particle dispersion or the inorganic nano oxide particle is 1: 5, and the particle diameter of the inorganic nano oxide particle is 5nm, the inorganic nano-oxide is nano-silicon oxide, the low-molecular-weight alcohol is methanol, and the low-molecular-weight alcohol sol of the inorganic nano-oxide particles is the alcohol sol of silicon oxide. Step 2, adding initiator and vinyl acetate monomer to the dispersion of inorganic nano-oxide particles or the low-molecular-weight alcohol sol of inorganic nano-oxide particles in sequence, ...

Embodiment 2

[0024] The specific steps of preparation are: step 1, disperse the inorganic nano-oxide particles into low-molecular-weight alcohol to obtain a dispersion of inorganic nano-oxide particles, or use the sol-gel method to obtain a low-molecular-weight alcohol sol of inorganic nano-oxide particles ; Wherein, the weight ratio between the inorganic nano-oxide particle and the low-molecular alcohol in the low-molecular alcohol sol of the inorganic nano-oxide particle dispersion or the inorganic nano-oxide particle is 1: 30, and the particle diameter of the inorganic nano-oxide particle is 5-30nm, the inorganic nano oxide is nano silicon oxide, the low molecular alcohol is methanol, and the low molecular alcohol sol of the inorganic nano oxide particles is the silicon oxide alcohol sol. Step 2, adding initiator and vinyl acetate monomer to the dispersion of inorganic nano oxide particles or the low molecular weight alcohol sol of inorganic nano oxide particles in sequence, and mixing t...

Embodiment 3

[0026] The specific steps of preparation are: step 1, disperse the inorganic nano-oxide particles into low-molecular-weight alcohol to obtain a dispersion of inorganic nano-oxide particles, or use the sol-gel method to obtain a low-molecular-weight alcohol sol of inorganic nano-oxide particles ; Wherein, the weight ratio between the inorganic nano oxide particle and the low molecular alcohol in the low molecular weight alcohol sol of the inorganic nano oxide particle dispersion or the inorganic nano oxide particle is 1: 50, and the particle diameter of the inorganic nano oxide particle is 50nm, the inorganic nano-oxide is nano-silicon oxide, the low-molecular-weight alcohol is methanol, and the low-molecular-weight alcohol sol of the inorganic nano-oxide particles is the alcohol sol of silicon oxide. Step 2, adding the initiator and vinyl acetate monomer to the dispersion of inorganic nano-oxide particles or the low-molecular-weight alcohol sol of inorganic nano-oxide particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com