Method for fast preparing n type Bi2(SexTe(1-x))3 thermoelectric material

A thermoelectric material and n-type technology, which is applied in the field of rapid preparation of n-type Bi23 thermoelectric materials, can solve the problems of long preparation time and large energy consumption, and achieve the effects of simple preparation process, low temperature and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

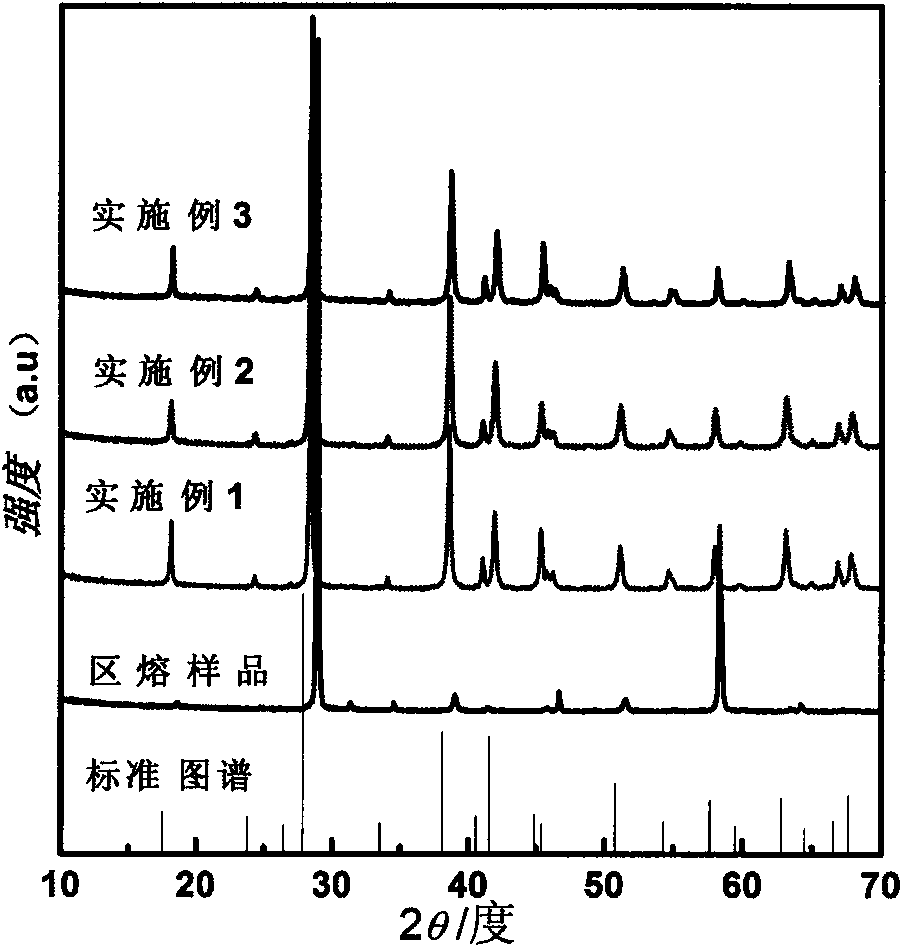

Embodiment 1

[0029] A rapid preparation of Bi 2 (Se 0.08 Te 0.92 ) 3 The method for thermoelectric material, it comprises the steps:

[0030] 1). According to the molar ratio of Bi powder, Te powder and Se powder is 2:0.24:2.76, weigh Bi powder, Te powder and Se powder {that is, use Bi powder, Te powder and Se powder as raw materials, according to Bi powder 2 (Se 0.08 Te 0.92 ) 3 Stoichiometric proportioning}; the total amount of Bi powder, Te powder and Se powder is weighed 5g; Bi powder, Te powder and Se powder are mixed and put into a 10mm steel mold and pressed into a block material on a tablet machine; the Bi powder , Te powder, Se powder purity ≥ 99.99% (mass);

[0031] 2). Put the pressed block material into the quartz tube of the single-roll quenching equipment, and under the protection of argon atmosphere, use high-frequency induction heating method to heat for 15 minutes at a current of 2-11A and a voltage of 100-500V. ~ 30 seconds, heat and melt the bulk material to obta...

Embodiment 2

[0036] A rapid preparation of Bi 2 (Se 0.1 Te 0.9 ) 3 The method for thermoelectric material, it comprises the steps:

[0037] 1). According to the molar ratio of Bi powder, Te powder and Se powder is 2:0.3:2.70, weigh Bi powder, Te powder and Se powder {that is, use Bi powder, Te powder and Se powder as raw materials, according to Bi powder 2 (Se 0.1 Te 0.9 ) 3 Stoichiometric proportioning}; the total amount of Bi powder, Te powder and Se powder is weighed 5g; Bi powder, Te powder and Se powder are mixed and put into a 10mm steel mold and pressed into a block material on a tablet machine; the Bi powder , Te powder, Se powder purity ≥ 99.99% (mass);

[0038] 2). Put the pressed block material into the quartz tube of the single-roll quenching equipment, and under the protection of argon atmosphere, use high-frequency induction heating method to heat for 15 minutes at a current of 2-11A and a voltage of 100-500V. ~ 30 seconds, heat and melt the bulk material to obtain a ...

Embodiment 3

[0043] A rapid preparation of Bi 2 (Se 0.12 Te 0.88 ) 3 The method for thermoelectric material, it comprises the steps:

[0044] 1). According to the molar ratio of Bi powder, Te powder and Se powder is 2:0.36:2.64, weigh Bi powder, Te powder and Se powder {i.e. take Bi powder, Te powder and Se powder as raw materials, according to Bi 2 (Se 0.12 Te 0.88 ) 3 Stoichiometric proportioning}; the total amount of Bi powder, Te powder and Se powder is weighed 5g; Bi powder, Te powder and Se powder are mixed and put into a 10mm steel mold and pressed into a block material on a tablet machine; the Bi powder , Te powder, Se powder purity ≥ 99.99% (mass);

[0045] 2). Put the pressed block material into the quartz tube of the single-roll quenching equipment, and under the protection of argon atmosphere, use high-frequency induction heating method to heat for 15 minutes at a current of 2-11A and a voltage of 100-500V. ~ 30 seconds, heat and melt the bulk material to obtain a unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com