Material of intermediate layer for centrifugally casting boracic high-speed steel composite rolls

A composite roll and centrifugal casting technology, which is applied to the middle layer material of centrifugal casting composite roll and the middle layer material of centrifugal casting boron-containing high-speed steel composite roll. problems, to achieve good metallurgical bonding, good casting performance, high strength and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

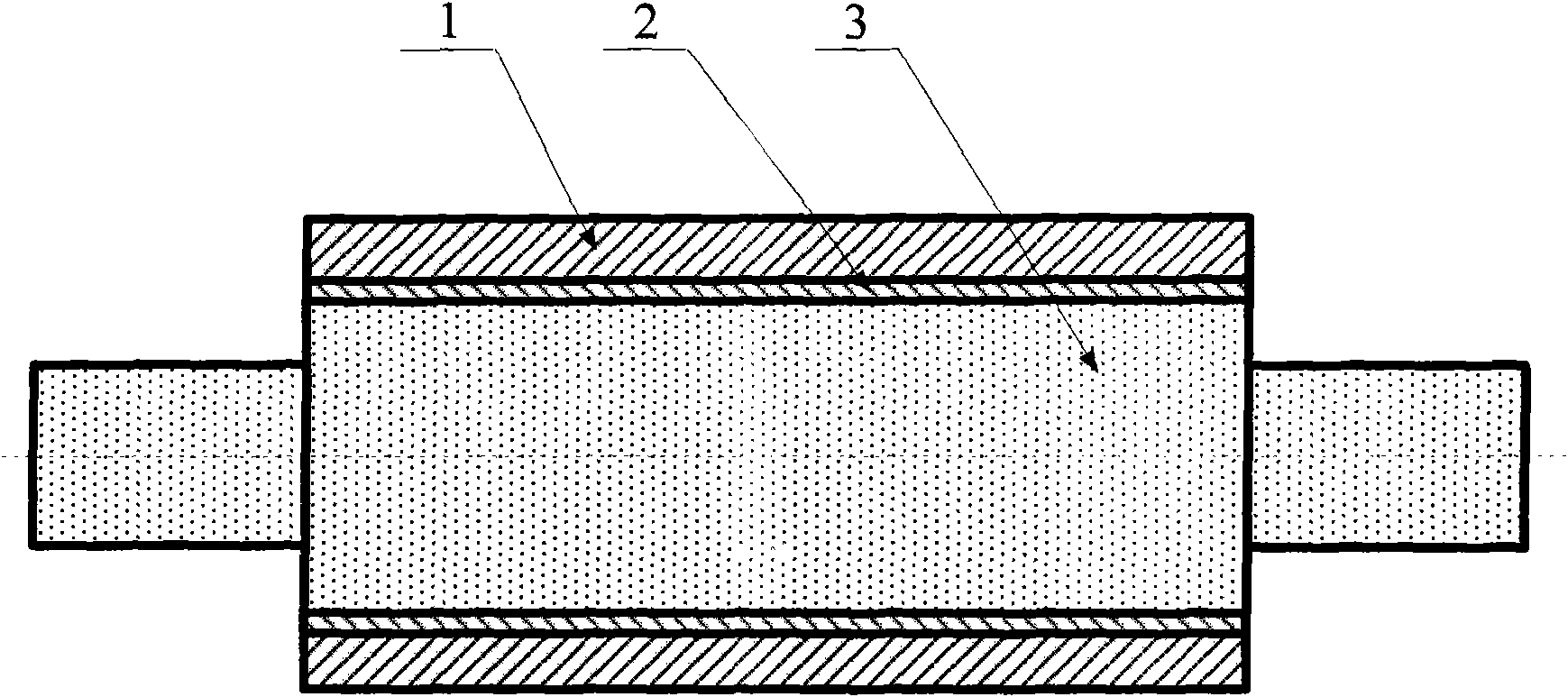

[0017] Pouring by centrifugal casting method High-speed steel composite roll, the outer layer is boron-containing high-speed steel 1, the thickness of the outer layer is 45mm, the roll core is ductile iron 3, the material of the present invention is used as the middle layer 2, the thickness of the middle layer 2 is 5mm, and the middle layer 2 adopts a 500 kg intermediate frequency induction Electric furnace smelting. First, scrap steel, pig iron and copper plate are mixed and heated and melted. Elements such as boron, vanadium, molybdenum, niobium, cobalt, tungsten and chromium are mainly brought in by the outer boron-containing high-speed steel, and the insufficient part is supplemented by adding ferroalloy. After the composition is adjusted before the furnace, the temperature is raised to 1525°C, then aluminum is used for deoxidation, and then ferrotitanium is added and released from the furnace. When the furnace is released, the molten steel is first inoculated with silico...

Embodiment 2

[0021] Pouring by centrifugal casting method High-speed steel composite roll, the outer layer is boron-containing high-speed steel 1, the thickness of the outer layer is 62mm, the roll core is ductile iron 3, the material of the present invention is used as the middle layer 2, the thickness of the middle layer 2 is 8mm, and the middle layer 2 adopts a 500 kg intermediate frequency induction Electric furnace smelting. First, scrap steel, pig iron and copper plate are mixed and heated and melted. Elements such as boron, vanadium, molybdenum, niobium, cobalt, tungsten and chromium are mainly brought in by the outer boron-containing high-speed steel, and the insufficient part is supplemented by adding ferroalloy. After adjusting the composition before the furnace, the temperature is raised to 1538°C, then aluminum is used for deoxidation, and then ferrotitanium is added and released from the furnace. When the furnace is released, the molten steel is first inoculated with silicon-...

Embodiment 3

[0025] Pouring by centrifugal casting method High-speed steel composite roll, the outer layer is boron-containing high-speed steel 1, the thickness of the outer layer is 50mm, the roll core is ductile iron 3, the material of the present invention is used as the middle layer 2, the thickness of the middle layer 2 is 6mm, and the middle layer 2 adopts a 500 kg intermediate frequency induction Electric furnace smelting. First, scrap steel, pig iron and copper plate are mixed and heated and melted. Elements such as boron, vanadium, molybdenum, niobium, cobalt, tungsten and chromium are mainly brought in by the outer boron-containing high-speed steel, and the insufficient part is supplemented by adding ferroalloy. After adjusting the composition before the furnace, the temperature is raised to 1520°C, then deoxidized with aluminum, then added ferro-titanium and taken out of the furnace. When the furnace is released, the molten steel is first inoculated with silicon-calcium-barium,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com