Piston-shaped bone repairing support and application thereof

A bone repair and piston technology, applied in the field of stents, can solve the problems of hindering new bone and sinus mucosa crawling replacement repair, material displacement and discharge, which have not been reported, so as to promote vascularization and new bone formation, prevent movement, good fix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

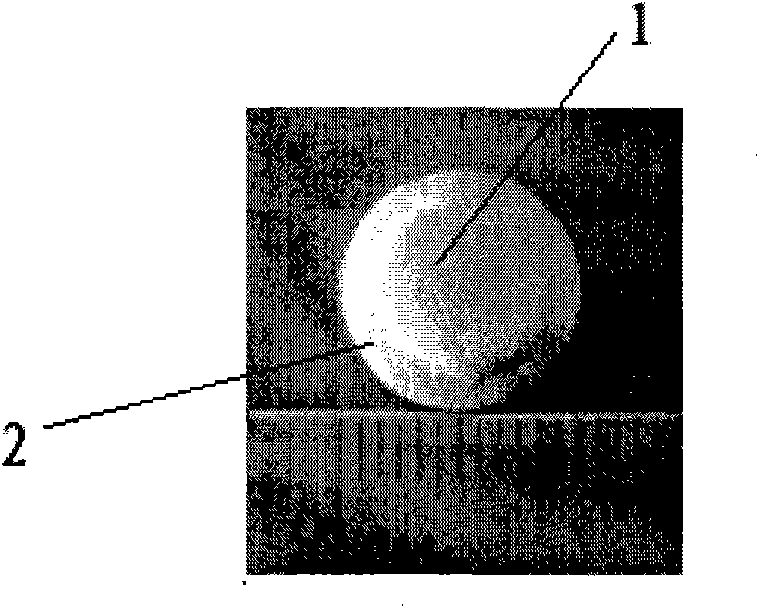

[0039] Please refer to Figure 1A , Figure 1B .

[0040] Figure 1A , Figure 1B It is a piston-shaped bone repair bracket, which consists of a bracket top 1 and a bracket bottom 2, the shape of the bracket top 1 and the bracket bottom 2 is circular, the diameter of the bracket top 1 is 10 mm, and the diameter of the bracket bottom 2 is 12 mm , the thickness of the top 1 of the bracket is 1 mm, and the thickness of the bottom 2 of the bracket is 2 mm. The preparation method of the piston-shaped bone repair bracket is as follows: use a resin model to carry out silicone rubber to take a negative mold, stir the β-tricalcium phosphate powder into a paste, inject it into the mold, put it in a drying oven at 80°C for 12 hours, and then Perform microwave sintering for one-shot molding. Co 60 (25kGy) is sterilized and individually packaged for use.

Embodiment 2

[0042]Using computer-aided design and manufacturing technology, the piston-shaped bone repair scaffold is prepared according to the shape of the specific defect. Contents include: design of Plug (piston)-shaped bone repair bracket; precise prefabrication of piston-shaped bone repair bracket according to the specific shape of bone defect; design of orbital wall bone repair with special shape through calculation of orbital volume and surgical simulation Scaffolds; methods for bone repair scaffolds complexed with cells or (and) growth factors in vitro.

[0043] 1. Design of Bone Repair Scaffold

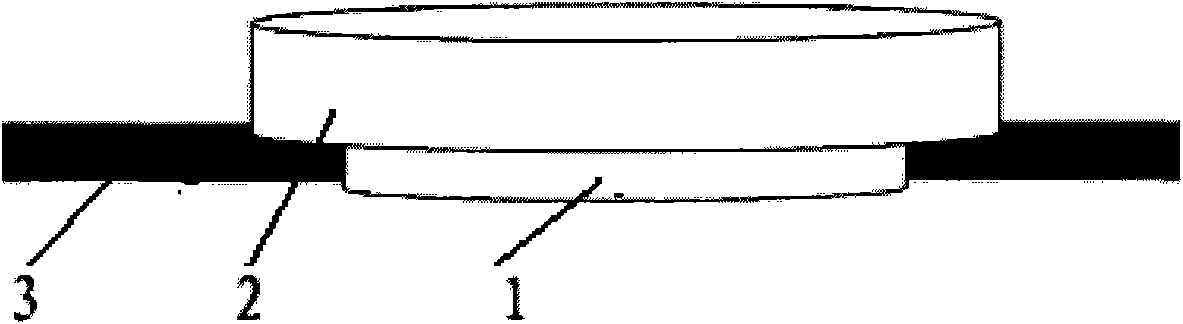

[0044] Design the material as a "Plug" pattern (see figure 2 ), consisting of two parts: the top of the bracket 1 and the bottom of the bracket 2: the top of the bracket 1 is inserted into the bone defect, and the bottom of the bracket 2 covers the normal bone wall. The main function of the top 1 of the bracket is to fill the bone defect and make close contact with the broken end of t...

Embodiment 3

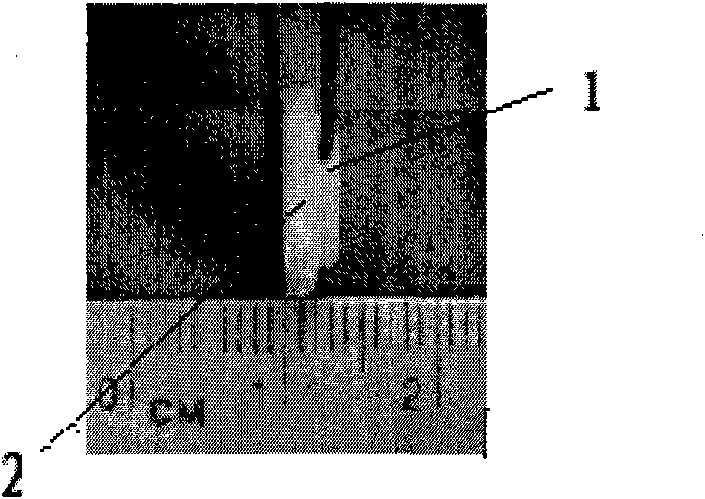

[0055] Design and Fabrication of Bone Repair Scaffold for Repairing Canine Orbital Wall Defects

[0056] 1. Establishment of canine medial orbital wall defect model

[0057] Select the skin incision of the lower eyelid and inner canthus, separate the subcutaneous tissue and muscles, and fully expose the medial wall of the orbit. The periosteum is incised and stripped with a dissector. A 10mm-diameter orthopedic trephine was used to create a circular full-thickness defect with a diameter of 10mm at the ethmoid cardboard on the medial orbital wall, destroying the periosteum and orbital septum, and causing orbital contents to incarcerate and herniate into the ethmoid sinus.

[0058] 2. Design and manufacture of "piston"-shaped bone repair bracket according to canine orbital wall defect

[0059] The shape of the bone defect in the dog’s orbital wall is a circle with a diameter of 10 mm. According to the design principle of the bone repair bracket, the orbital wall repair materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com