A molecular sieve catalyst for preparing low-carbon olefins and its preparation method

A low-carbon olefin and catalyst technology, which is applied in the field of shaped molecular sieve catalyst and the preparation method of the catalyst, can solve the problems of low propylene selectivity, decreased propylene selectivity, poor catalyst stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Take 100g of ZSM-5 zeolite powder (SAR=200), add 25g alumina, 2g methylcellulose and 3g sesame powder to it, mix the above raw materials uniformly, and set the liquid-solid ratio to 1.5mL nitric acid / 2g zeolite The mass percentage of 20% nitric acid solution is used as peptizer, and then 3.4g La(NO 3 ) 3 ·6H 2 O's miscellaneous element modifier. The other preparation steps are the same as in Comparative Example 1, and the obtained catalyst is labeled S-1, and the catalyst contains 1% La by mass percentage. S-1 was crushed, and particles of 20-40 mesh were screened out for activity evaluation. The reaction was fed with a mixture of methanol and water (mass ratio CH 3 OH: H 2 O=2:1), the catalyst activity evaluation results are shown in Table 1. The catalyst activity evaluation results are shown in Table 1.

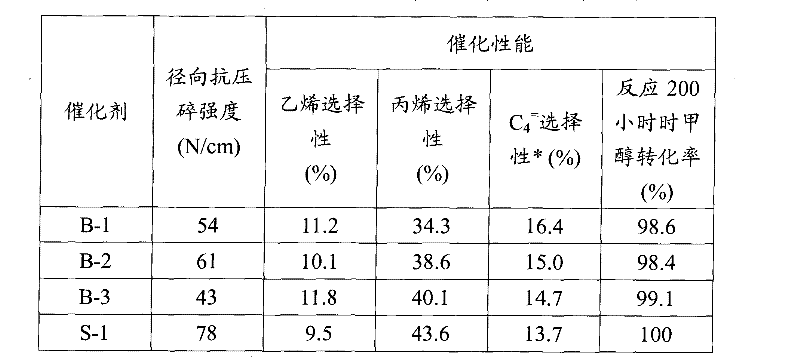

[0047] As shown in Table 1, under the conditions of the same methanol conversion rate, the La modification of ZSM-5 zeolite is beneficial to increase the selectivity o...

Embodiment 2-11

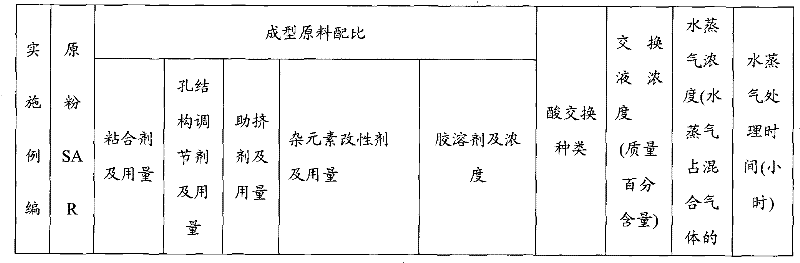

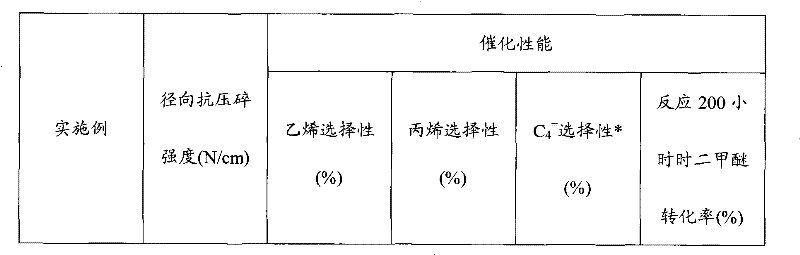

[0052] Weigh 100g of sodium-type ZSM-5 zeolite with SAR of 300, 400, 500, 600 and 700 respectively for molding, add one or more different binders and pore structure modifiers, and then add peptizer and miscellaneous element modification Sex agent. The peptizer is nitric acid, sulfuric acid, hydrochloric acid, phosphoric acid, formic acid, acetic acid or malonic acid, and the amount added is based on the liquid-solid ratio of 1.5mL / 2g zeolite. The type and concentration of acid used for ion exchange, water vapor concentration and treatment The time is specifically listed in Table 2. The miscellaneous element modifier is one or more of soluble precursors containing Mg, P, In, Zn, Cu, Mn, Ga, Sr and Ca. As shown in 2, the other preparation steps of the shaped catalyst are the same as in Example 1. The reaction is fed with a mixture of dimethyl ether and water (mass ratio CH 3 OCH 3 : H 2 O=2:1), the catalyst activity evaluation results are shown in Table 2.

[0053] Table 2 The ra...

Embodiment 12

[0057] Take 100g of ZSM-5 sodium zeolite powder (SAR=1000), add 2.0g sesame powder and 2.0g starch to it, mix the above raw materials uniformly to form a mixture. Put 3.4g La(NO 3 ) 3 ·6H 2 O is dissolved in 75 g of a silica sol solution with a mass percentage of 33.3% to form a mixed solution. This mixed solution was slowly added to the above mixture, mixed uniformly, and extruded into a Φ2×5mm strip, dried at 80°C under constant temperature in air atmosphere for 12h, and calcined at 600°C for 5h. According to the liquid-to-solid ratio of 10mLHCl / 1g zeolite, the HCl solution with a mass percentage of 4% was exchanged 3 times at 60°C, each for 2h. Wash with deionized water and dry at 120°C to obtain H-ZSM-5 zeolite. Use H 2 O volume percentage of H is 40% 2 O / N 2 The gas is treated at 600°C for 8 hours, the catalyst obtained is broken, and the reaction is mixed with dimethyl ether and water as feed (mass ratio CH 3 OCH 3 : H 2 O=2:1), sieving out 20-40 mesh particles for activ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com