High energy density lithium secondary battery electrode and preparation method thereof

A lithium secondary battery, high energy density technology, applied in the fields of electrochemistry, material chemistry and chemical power products, can solve the problems of reducing the relative content of electrochemical active materials, reducing the actual specific energy of the battery, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

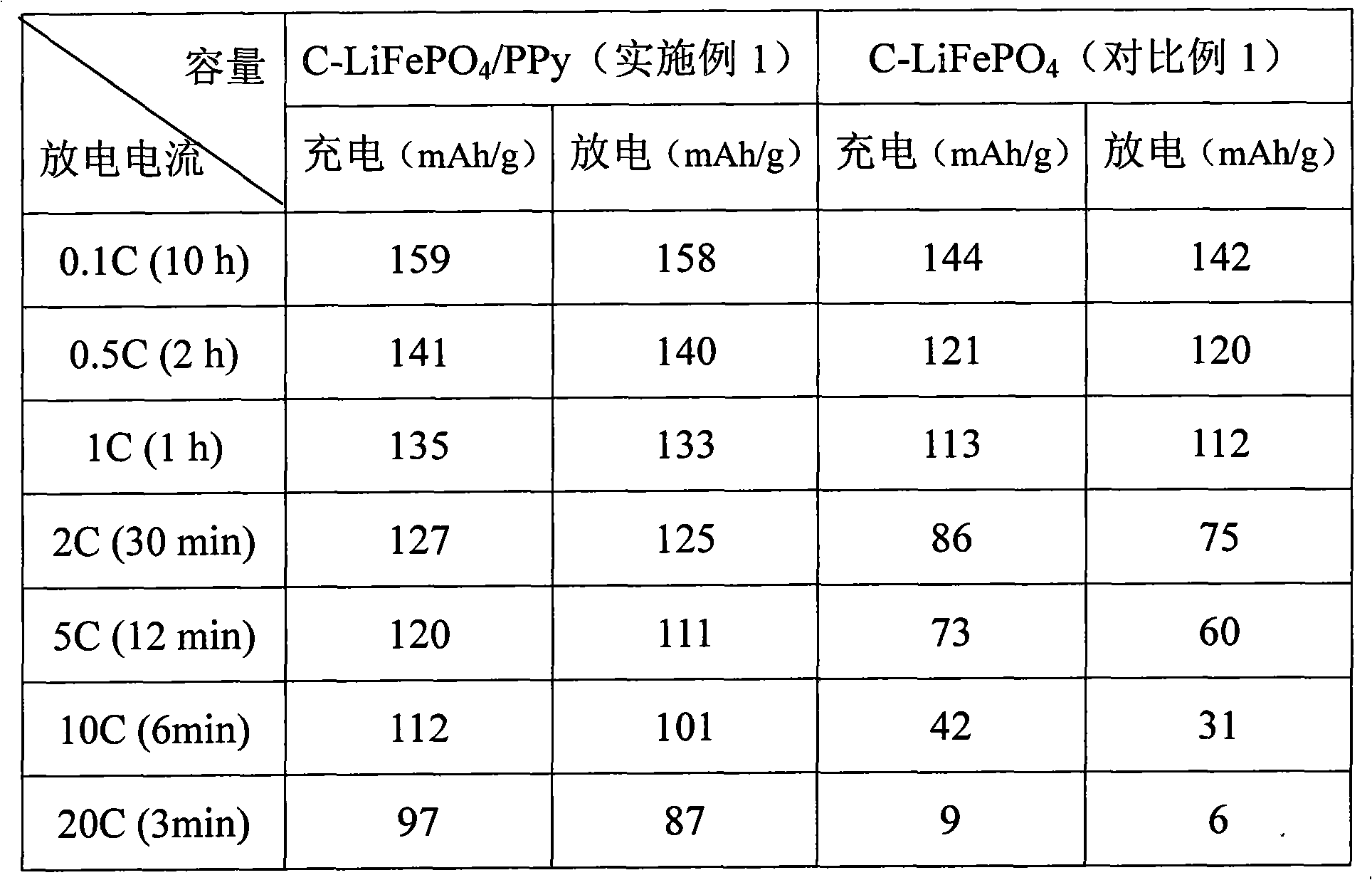

Embodiment 1

[0023] Example 1 First prepare 100ml of 0.1mol / L pyrrole Py acetonitrile solution, add 1g of carbon-coated lithium iron phosphate C-LiFePO 4 powder and 0.2 g of supporting electrolyte LiClO 4 , sonicated for half an hour to obtain a uniform suspension, and then the stainless steel mesh was used as the working electrode, and the counter electrode was placed in the suspension, and 0.1mA / cm was applied to the working electrode. 2 The constant current electrochemical polymerization was carried out at a current density of 1 hour. After 1 hour of polymerization, a uniform layer of PPy-coated C-LiFePO was obtained on the working electrode. 4 Composite film of C-LiFePO by differential thermal analysis 4 : PPy=84:16, directly use the working electrode as the positive electrode of the battery, the metal lithium sheet as the negative electrode, the polypropylene microporous membrane as the separator, and the 1mol / L LiPF 6 The / EC-DMC (1:1) solution was used as the electrolyte to assemb...

Embodiment 2

[0026] Example 2 First prepare 100ml of 0.01mol / L aniline in acetonitrile solution, then add 2g lithium titanate Li 4 Ti 5 o 12 Powder, 0.5g supporting electrolyte LiPF 6 , 0.02g conduction aid carbon black CB and 0.02g conduction aid graphite, 0.01g adhesion aid polytetrafluoroethylene PTFE, ultrasonically dispersed for 2 hours to obtain a uniform suspension, then foam nickel as a working electrode, and to The electrode was placed in the suspension, and cyclic voltammetric electrochemical polymerization was performed in the potential range of 1.3V to 0.1V (relative to the Ag / AgCl reference electrode). After 1.2 hours of reaction, a layer of polyaniline was evenly deposited on the working electrode. Coated Li 4 Ti 5 o 12 The film of Li was obtained by differential thermal analysis 4 Ti 5 o 12 : PPy: PTFE: (CB+graphite) = 93: 2: 2: 3, directly use this electrode as the working electrode of the battery, use the lithium metal sheet as the counter electrode of the battery,...

Embodiment 3

[0027] Embodiment 3 First prepare the acetonitrile solution of 100ml 0.2mol / L p-phenylene PP, add 1gLiMn 2 o 4 Powder, 0.2g supporting electrolyte LiClO 4 and 0.1g bonding aid polytetrafluoroethylene PTFE, ultrasonic vibration for 1 hour to obtain a uniform suspension, then the aluminum mesh was used as a working electrode, and the counter electrode was placed in the suspension, and 1.2 The potential of V (relative to the Ag / AlCl reference electrode) was subjected to potentiostatic electrochemical polymerization, and a uniform layer of polypyrrole-coated LiMn was obtained on the working electrode after polymerization for 0.5 hours. 2 o 4 Composite film of LiMn by differential thermal analysis 2 o 4 : PPy: PTFE = 70: 22: 8, directly use the working electrode as the working electrode of the battery, the lithium sheet as the negative electrode, the polypropylene microporous membrane as the separator, and the 1mol / L LiPF 6 / EC-DMC (1:1) solution is the electrolyte to assemble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com