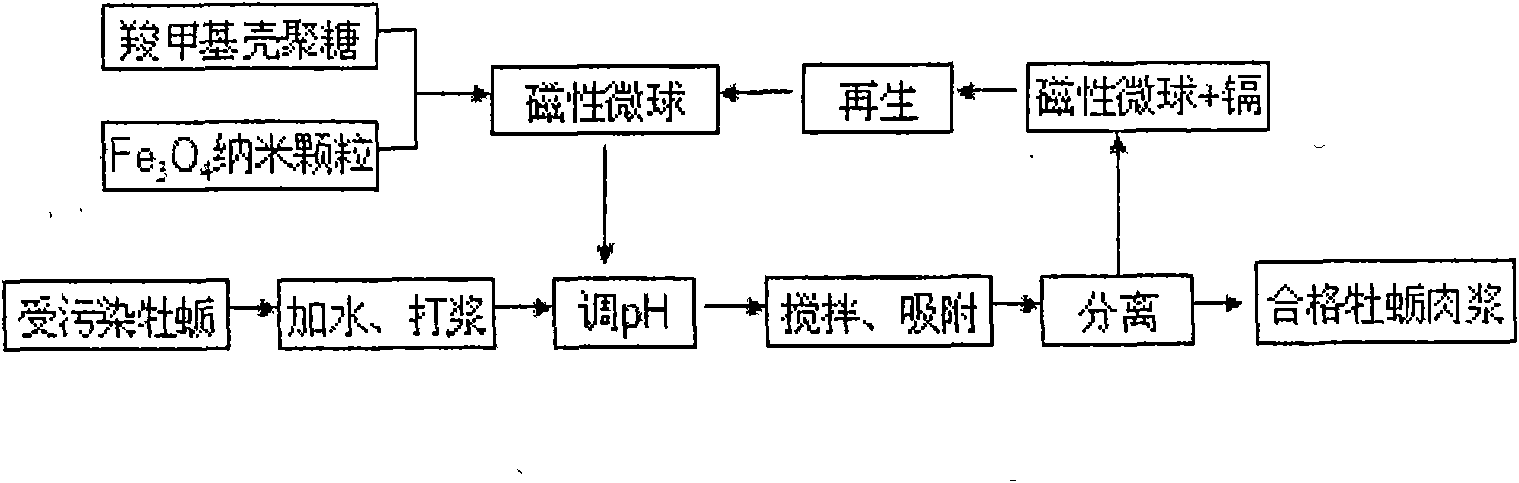

Methods for preparing carboxymethyl chitosan magnetic microspheres and adsorbing cadmium in oyster meat by using carboxymethyl chitosan magnetic microspheres

A technology of carboxymethyl chitosan and magnetic microspheres, which is applied in microsphere preparation, food preparation, microcapsule preparation and other directions, can solve problems such as waste, and achieve the effects of simple production method, convenient use and avoidance of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh ferrous chloride and ferric chloride and mix them according to 2:1, add ammonia water dropwise under the protection of nitrogen to make the pH 10, stir to form black precipitate, wash and dry in vacuum to prepare Fe 3 o 4 nanoparticles. Then make carboxymethyl chitosan into 2% aqueous solution, and Fe 3 o 4 Nanoparticles were mixed according to the mass ratio of raw materials at 2:1, added to liquid paraffin, and Tween 80 was added, sodium sulfate was added to form a precipitate, glutaraldehyde was added, the temperature was raised to 40°C and stirred for 1 hour, then the temperature was raised to 60°C, and stirred for 5 hours , washed after separation, and vacuum-dried.

[0023] Shell the oysters and take the meat, add water that meets the drinking standard according to the ratio of material to liquid 1:2, beat, filter off the residue, add hydrochloric acid to make the pH 3, add the prepared magnetic microspheres according to 2% of the amount of oysters, and s...

Embodiment 2

[0026] Weigh ammonium ferrous sulfate and ammonium ferric sulfate according to 1:1, add ammonia water dropwise under the protection of nitrogen to make the pH 10, stir to form black precipitate, wash and dry in vacuum to prepare Fe 3 o 4 nanoparticles. Then make carboxymethyl chitosan into 1.5% aqueous solution, and Fe 3 o 4 Nanoparticles are mixed according to the mass ratio of raw materials at 5:1, added to liquid paraffin, and Span 80 is added, sodium sulfate is added to form a precipitate, glutaraldehyde is added, the temperature is raised to 40°C and stirred for 2 hours, then heated to 60°C, stirred for 5 hours , washed after separation, and vacuum-dried.

[0027] Shell the oysters and take the meat, add water that meets the drinking standard according to the ratio of solid to liquid 1:5, beat, filter off the residue, add hydrochloric acid to make the pH 2.5, add the prepared magnetic microspheres according to 10% of the amount of oysters, and slowly Stir for 90 minut...

Embodiment 3

[0029] Weigh ferrous chloride and ferric chloride and mix them according to 1:2, add ammonia water dropwise under the protection of nitrogen to make the pH 10, stir to form black precipitate, wash and dry in vacuum to prepare Fe 3 o 4 nanoparticles. Then make carboxymethyl chitosan into 2.5% aqueous solution, and Fe 3 o 4 Nanoparticles are mixed according to the mass ratio of raw materials at 3:1, added to n-hexanol, and Tween 80 is added, sodium sulfate is added to form a precipitate, formaldehyde is added, the temperature is raised to 40°C and stirred for 2 hours, then heated to 60°C, stirred for 2 hours, separated After cleaning, vacuum dry.

[0030] Shell the oysters and take the meat, add water that meets the drinking standard according to the ratio of material to liquid 1:1, beat the pulp, filter off the residue, add hydrochloric acid to make the pH 3.5, add the prepared magnetic microspheres according to 5% of the oysters, and slowly Stir for 30 minutes, and use mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com