Method for screening active constituents capable of eliminating free radicals from natural products

A technology for natural products and active ingredients, applied in material separation, analytical materials, measurement devices, etc., can solve the problems of inability to measure, easily subject to substrate interference, and large demand for natural product raw materials, saving time, reducing Screening cost and the effect of less loss of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

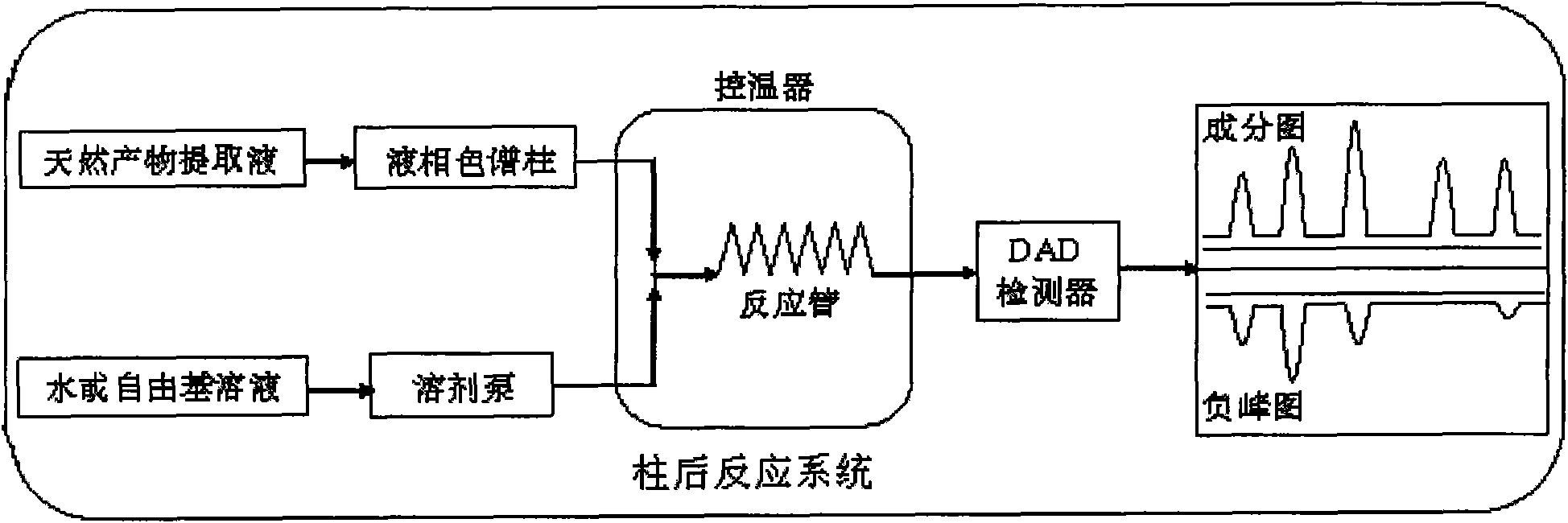

Method used

Image

Examples

Embodiment 1

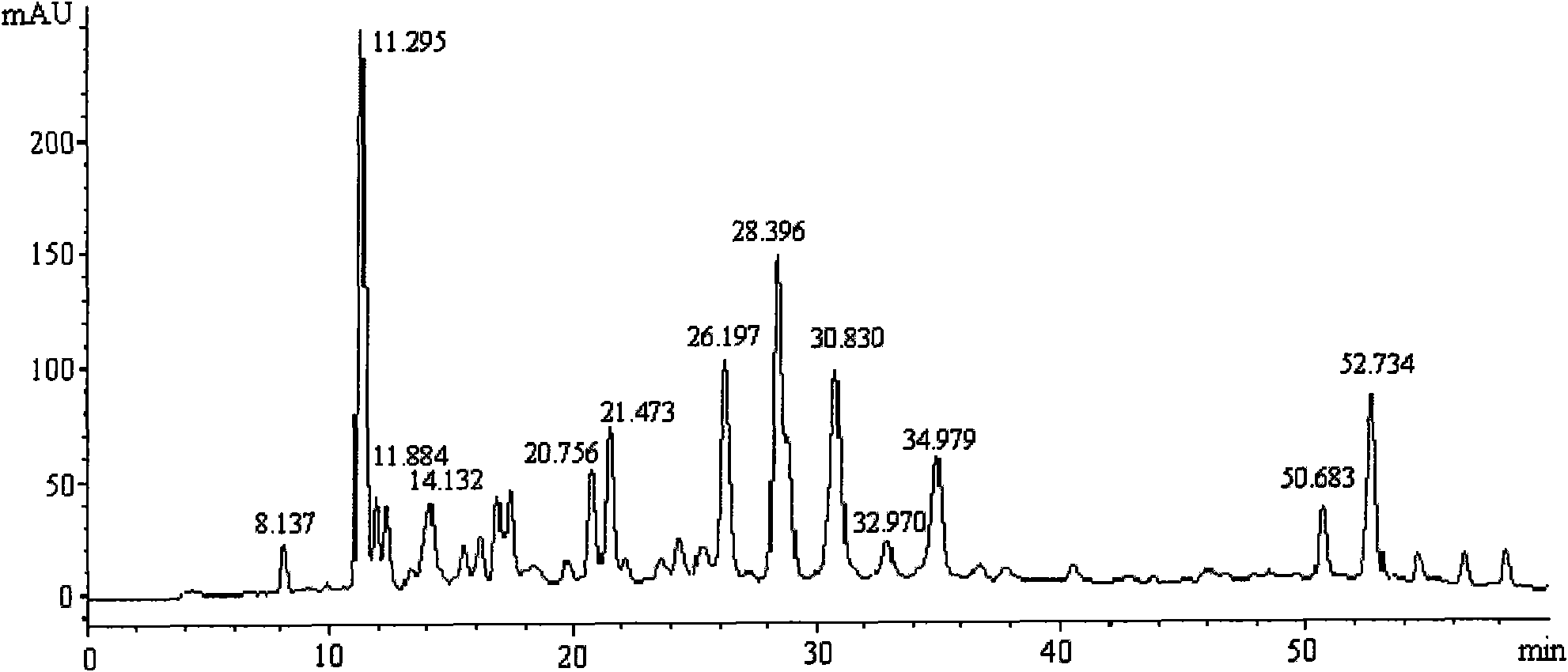

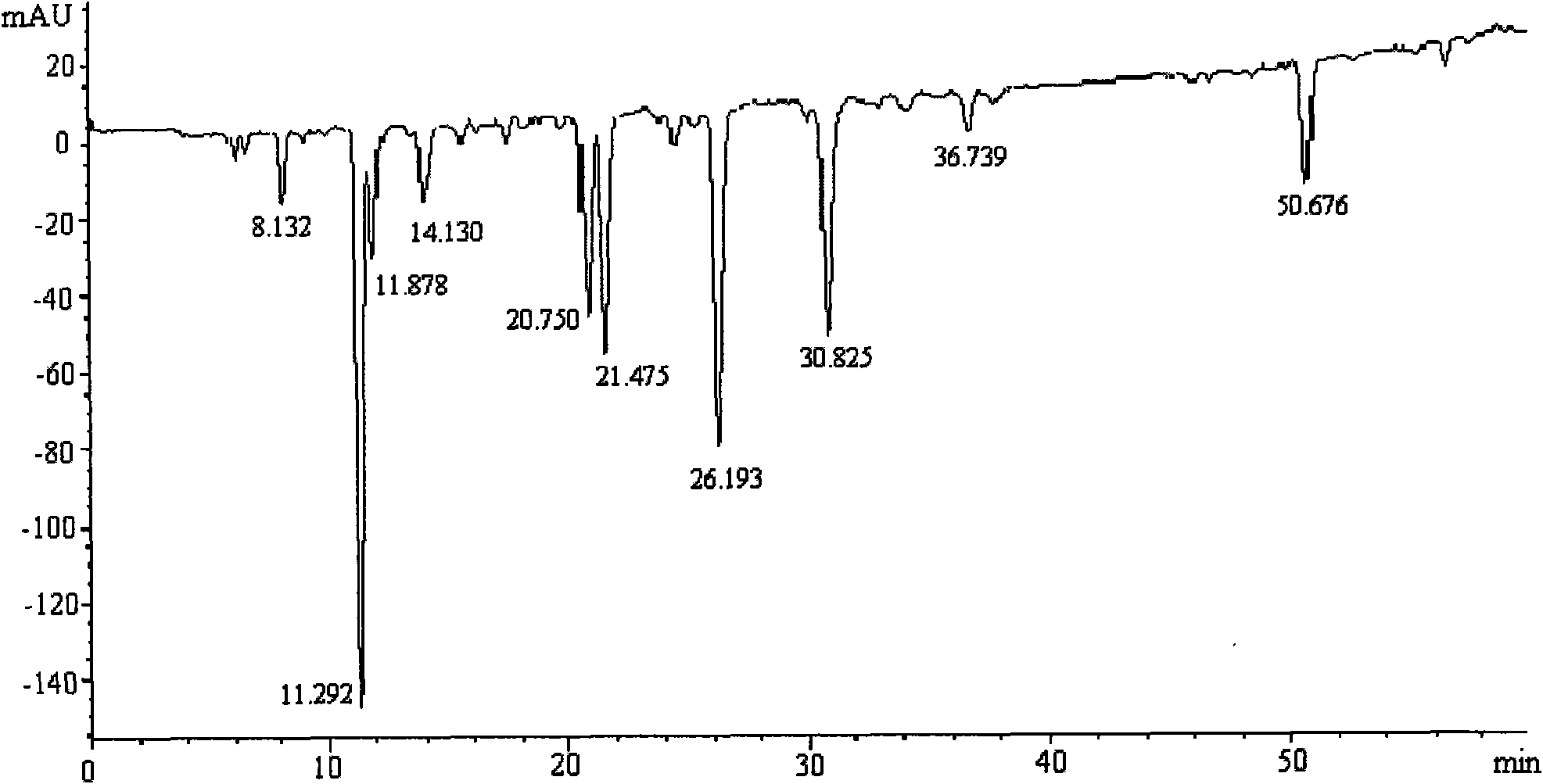

[0034] The fruit of the plant gardenia is a material with the same source of medicine and food, which has significant effects of protecting the liver, promoting gallbladder, lowering blood pressure and reducing inflammation. Cross 20 mesh sieves after the dried fruit of gardenia is crushed, get 5g dried fruit powder, add 50% ethanol aqueous solution 30 ℃ of water bath oscillations of 20 times of volumes wherein to extract 1 hour, 3000 rev / min centrifugal 10 minutes, after removing precipitation, The upper layer solution was concentrated in vacuo to remove ethanol, and the volume was adjusted to 10 mL with pure water. After passing this solution through the membrane (the pore size of the membrane is 0.45 μm), 10 μL was taken as a sample for high-performance liquid chromatography separation. The chromatographic column was a Zorbax SB-C18 column (4.6mm i.d.×250mm, 5 μm particle size, Agilent Company, the United States) The separation conditions are shown in Table 1 (mobile phase:...

Embodiment 2

[0039] Marigold oil-soluble ingredients are rich in lutein and vitamin E ingredients, which have activities such as scavenging free radicals in the body and anti-aging. After the commercially available marigold particles were pulverized, 20 g of the powder was weighed in a Soxhlet extractor, and 200 mL of n-hexane was used as the extraction solvent for Soxhlet extraction. The heating temperature was 80° C., and the extraction time was 8 hours. After the extraction is completed, the residue and the extract are included, and then the solvent n-hexane (40° C.) is removed from the extract with a vacuum rotary evaporator to obtain an oil-soluble component. Take 0.5 g of the oil, dissolve it in n-hexane to a constant volume of 10 mL, pass it through a membrane (the pore size of the membrane is 0.45 μm), and then take 10 μL of the oil for injection by high performance liquid chromatography. The liquid phase system is a normal phase separation system, and the chromatographic column is...

Embodiment 3

[0041] After the oil-soluble components of marigolds are extracted, the remaining residue is rich in active ingredients, which have good antioxidant and free radical scavenging activities. Take by weighing 1 g of the marigold residue after the oil-soluble component was extracted in Example 2, add 30 ml of 70% ethanol aqueous solution, shake and extract in a water bath at 30° C. for 24 hours, centrifuge at 3000 rpm for 10 minutes, remove the precipitate, and use the extract for 70 % ethanol solution to a volume of 50 mL. After the solution passes through the membrane (0.45 μm), 10 μL of sample is taken for HPLC separation, and the chromatographic column is a Zorbax SB-C18 column (4.6mm i.d.×250mm, 5 μm particle size, Agilent Company, the United States). The separation conditions are shown in Table 2 (Mobile phase: 20% methanol: water (0.25% formic acid) and 100% methanol gradient elution), the separated components flow through the post-column reaction system, and then detected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com