Liquid dairy product containing linoleic acid and linolenic acid and preparation method thereof

A technology for dairy products and linolenic acid, applied in dairy products, food preparation, milk preparations, etc., can solve the problems of poor stability, not very wide application, liquid milk fat separation and "bleaching oil".

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

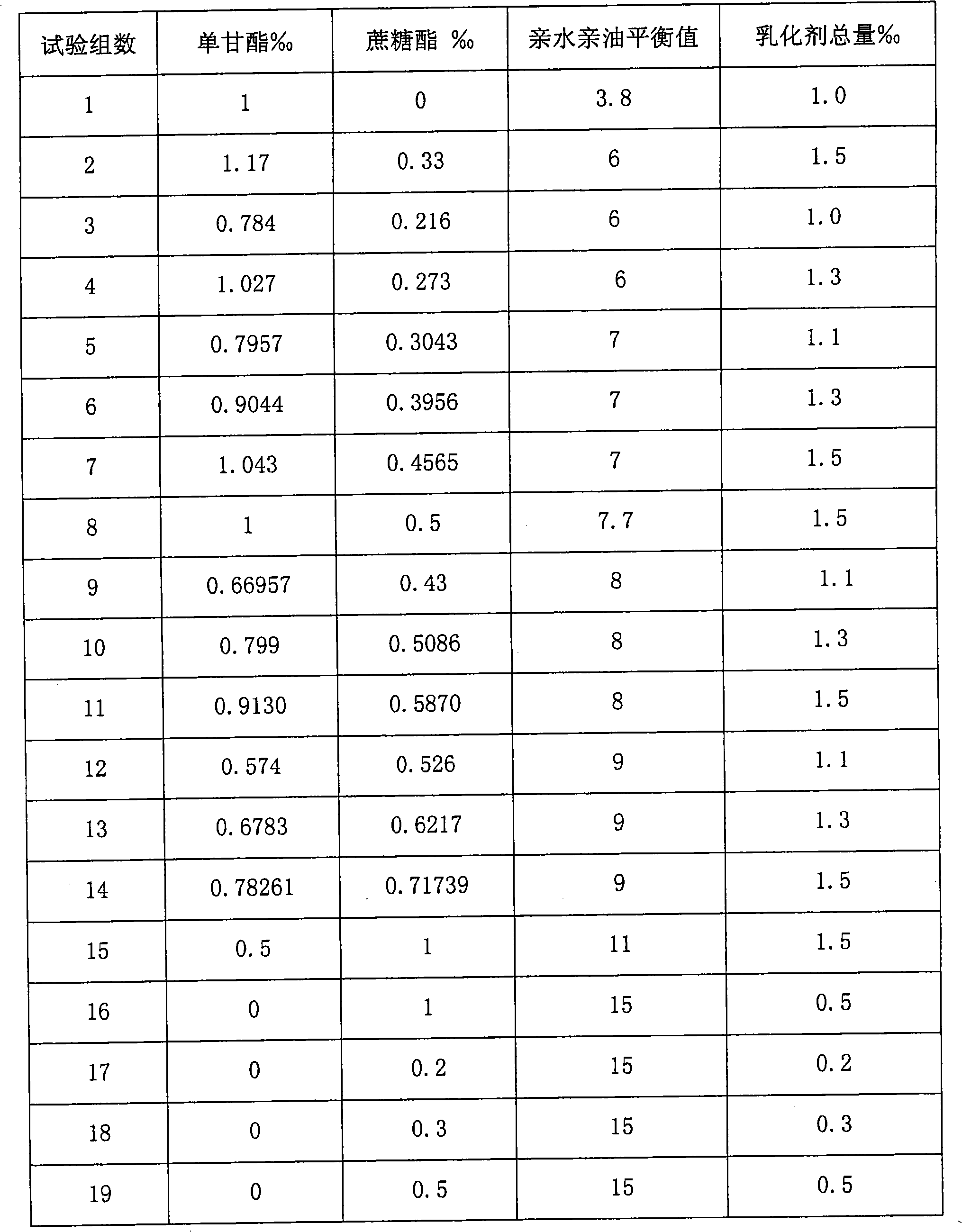

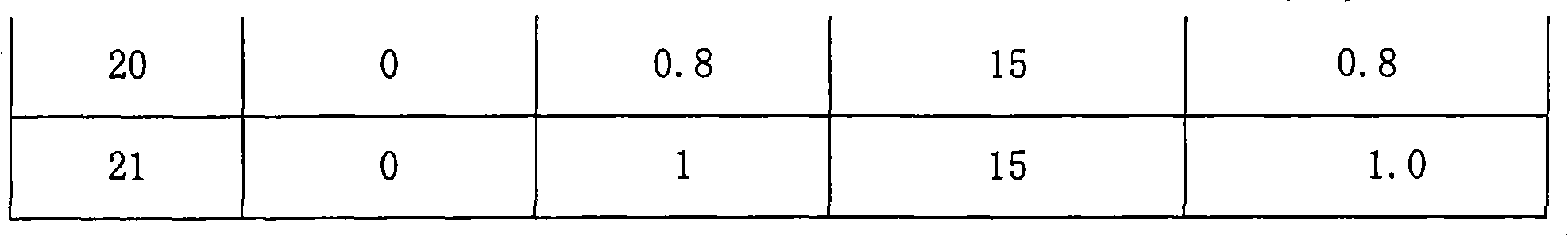

Method used

Image

Examples

Embodiment 1

[0095] 800 servings of fresh milk

[0096] Palm oil 50 parts

[0097] 4 parts linolenic acid

[0098] Concentrated whey protein powder 10 servings

[0099] 50 parts white sugar

[0100] Sodium alginate 0.5 parts

[0101] Lamda carrageenan 0.1 parts

[0102] Diacetyl tartaric acid monoglyceride 1.0 parts

[0103] Glyceryl monostearate 1.0 parts

[0104] Sodium stearoyl lactylate 0.3 parts

[0105] 0.3 servings of nutrients

[0106] Nutrient II 0.05 parts

[0107] Nutrient 3 0.1 part

[0108] 1 part honey

[0109] Essence 0.1 part

[0110] 81.55 parts of purified water.

[0111] 0.3 Serving Nutrient One contains the following ingredients: (per 1000g product)

[0112] V B1 400-800ug

[0113] V B2 400-800ug

[0114] Niacin 4000ug-5000ug

[0115] V C 80-100mg

[0116] 5'nucleotide 20-58mg

[0117] Lutein 30-200ug.

[0118] 0.05 serving of Nutrient Two contains the following ingredients:

[0119] V A 1250-2500IU

[0120] V D 200-400IU

[0121] V ...

Embodiment 2

[0145] 500 servings of whole milk

[0146] 32 parts soybean oil

[0147] 5 parts of linolenic acid

[0148] Concentrated whey powder 9 servings

[0149] 50 parts white sugar

[0150] Microcrystalline cellulose 1.0 parts

[0151] Sodium alginate 0.3 parts

[0152] 0.1 part of sucrose fatty acid ester

[0153] Diacetyl tartaric acid monoglyceride 1.0 parts

[0154] Sodium stearoyl lactylate 0.2 parts

[0155] 0.3 part of monoglyceride fatty acid ester

[0156] 2 parts honey

[0157] Nutrients 0.36 parts

[0158] 0.2 parts of essence

[0159] 389.54 parts of purified water

[0160] 0.36 servings Nutrient One contains the following ingredients:

[0161] V B1 400-800ug

[0162] V B2 400-800ug

[0163] Niacin 4000ug-5000ug

[0164] V C 80-100mg

[0165] 5'nucleotide 20-58mg

[0166] Lutein 30-200ug

[0167] A 0.05 serving of Nutrient Two contains the following ingredients:

[0168] V A 1250-2500IU

[0169] V D 200-400IU

[0170] V E 5.0IU-7IU

[01...

Embodiment 3

[0181] 600 servings of fresh milk

[0182] 40 parts of corn oil

[0183] 4 parts linolenic acid

[0184] Whey powder 11.25 parts

[0185] 45 parts white sugar

[0186] 0.5 parts of gellan gum

[0187] Xanthan gum 0.5 parts

[0188] 0.3 part of monostearic acid glyceride

[0189] Sodium stearoyl lactylate 0.15 part

[0190] Diacetyl tartrate monoglyceride 0.7 part

[0191] 1.8 parts of honey

[0192] Nutrients 0.35 parts

[0193] 0.5 parts of essence

[0194] 294.95 parts of purified water

[0195] 0.35 servings of Nutrient One contains the following ingredients:

[0196] V B1 400-800ug

[0197] V B2 400-800ug

[0198] Niacin 4000ug-5000ug

[0199] V C 80-100mg

[0200] 5'nucleotide 20-58mg

[0201] Lutein 30-200ug

[0202] A 0.05 serving of Nutrient Two contains the following ingredients:

[0203] V A 1250-2500IU

[0204] V D 200-400IU

[0205] V E 5.0IU-7IU

[0206] V K1 22ug-75ug

[0207] 0.1 serving of Nutrient Three contains the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com