Epoxy resin and preparation method thereof

A technology of epoxy resin and epihalohydrin, applied in the field of resin and its preparation, can solve the problems of insufficient high-frequency characteristics, high dielectric constant and dielectric loss tangent, inability to adapt to the high frequency of signals, etc. The effect of optimized electrical properties, simple operation, high thermal stability and resistance to humidity and heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

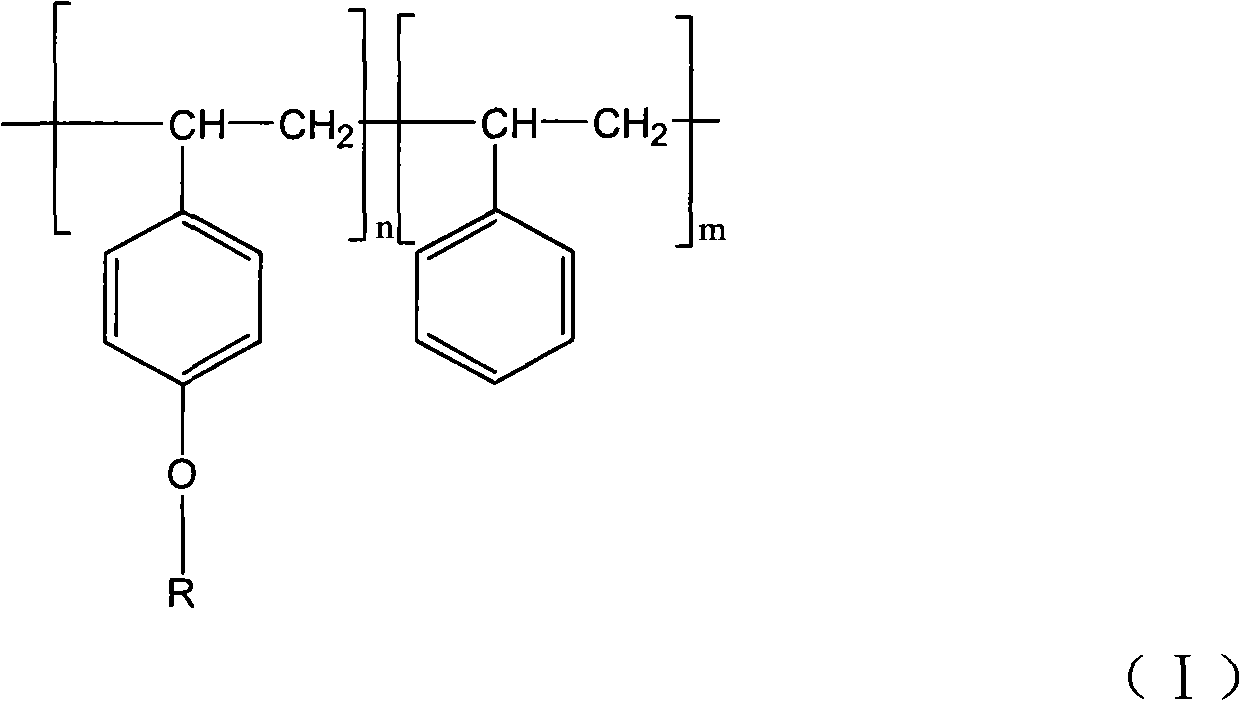

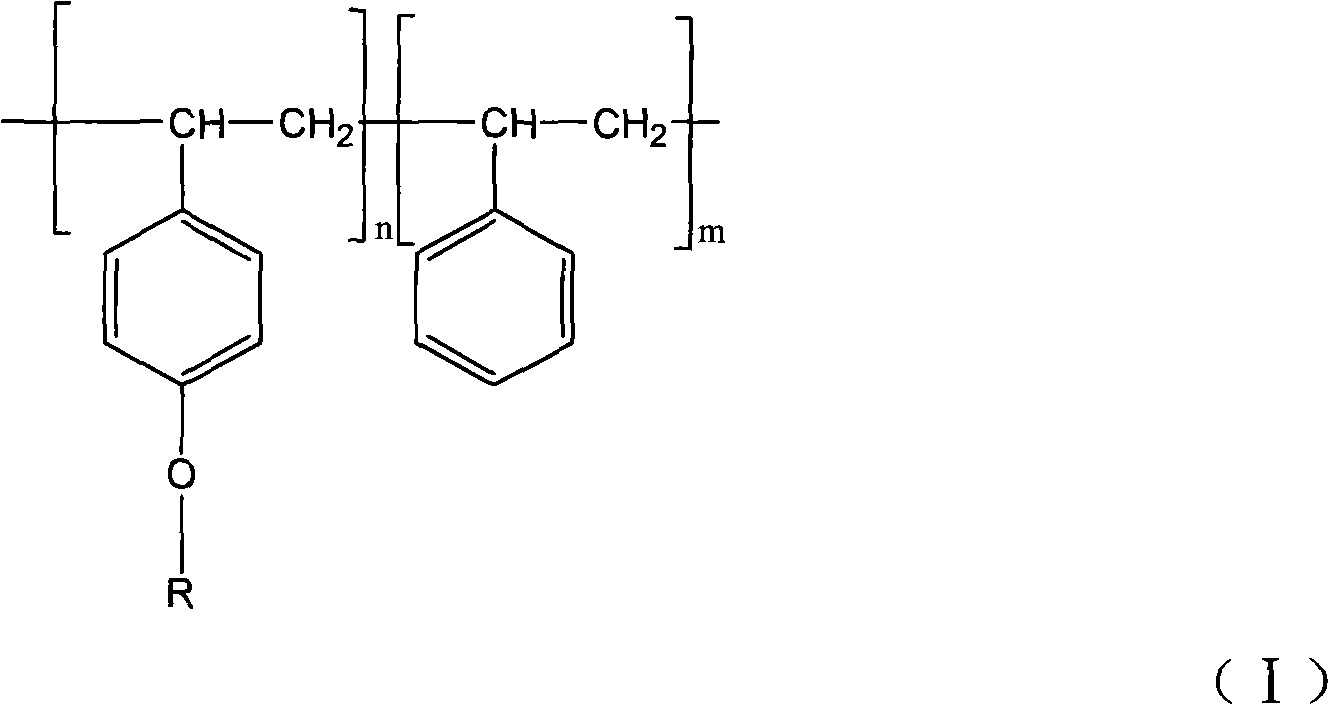

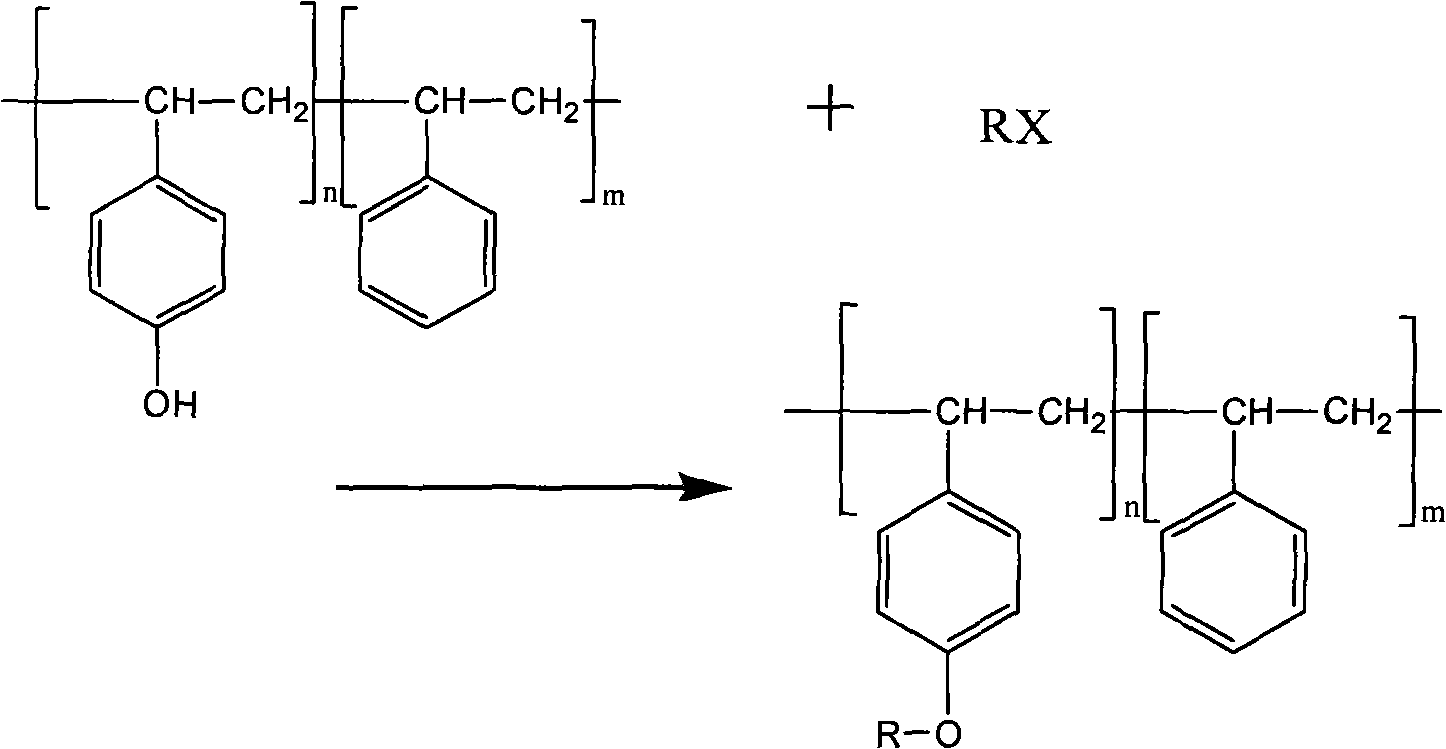

[0028] The invention provides a preparation method of epoxy resin. The method adopts a one-step method, that is, the mixture of p-hydroxystyrene / styrene copolymer and epichlorohydrin is directly condensed under the action of alkali to obtain the epoxy resin. The specific steps are: mixing organic solvent, p-hydroxystyrene / styrene copolymer and epichlorohydrin, feeding p-hydroxystyrene / styrene copolymer and epichlorohydrin at a molar ratio of 1:1 to 20, inert Heating and reacting at 50-150°C for 1 to 5 hours under gas protection, while adding lye dropwise, the molar ratio of lye and p-hydroxystyrene / styrene copolymer is 1 to 2:1, after the reaction is completed, filter and wash with water Salt content is removed, excess epichlorohydrin is removed by vacuum distillation, and finally a multifunctional epoxy resin containing a low-polarity styrene structure is obtained.

[0029] The lye used therein can be sodium hydroxide, potassium hydroxide, etc. The lye used is preferably a th...

Synthetic example 1

[0049] Mix p-hydroxystyrene / styrene copolymer, epichlorohydrin and dioxane, and feed the p-hydroxystyrene / styrene copolymer and epichlorohydrin at a molar ratio of 1:5. Dioxane has a p-hydroxystyrene / styrene copolymer weight ratio of 1.89. p-Hydroxystyrene / styrene copolymer synthesized by known method, Wn is 4300. Above-mentioned mixture is heated under nitrogen protection, and heating temperature is at 80 degree, and constantly stirs, and dropwise adds sodium hydroxide solution simultaneously, the concentration of used sodium hydroxide solution is 25wt%, sodium hydroxide and p-hydroxystyrene / styrene copolymer The molar ratio of the lye is 2 / 1, and the lye is added dropwise within 3 hours. During the reaction process, the moisture and epichlorohydrin in the system are continuously separated from the system by azeotropic, and the stratified epichlorohydrin returns to the system. Excess epichlorohydrin and dioxane were distilled off under reduced pressure, methyl isobutyl keton...

Synthetic example 2

[0051] Mix p-hydroxystyrene / styrene copolymer, epichlorohydrin and toluene, and feed the p-hydroxystyrene / styrene copolymer and epichlorohydrin at a molar ratio of 1:10. Dioxane has a p-hydroxystyrene / styrene copolymer weight ratio of 1.89. p-Hydroxystyrene / styrene copolymer synthesized by known method, Wn is 30000. Above-mentioned mixture is heated under the protection of nitrogen, heating temperature is at 100 degree, and constantly stirs, dropwise adds sodium hydroxide solution simultaneously, the concentration of used sodium hydroxide solution is 25wt%, sodium hydroxide and p-hydroxystyrene / styrene copolymer The molar ratio of the lye is 2 / 1, and the lye is added dropwise within 2 hours. During the reaction, the moisture and epichlorohydrin in the system are continuously separated from the system by azeotropy, and the stratified epichlorohydrin returns to the system. Excess epichlorohydrin and toluene were distilled off under reduced pressure, methyl isobutyl ketone was a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com