Preparation method of fluorinated hydroxy vinyl tertcarbonate-acrylate copolymer soap-free emulsion with core-shell structure

A technology of tertiary acrylic emulsion and core-shell structure, which is applied in the field of emulsion preparation, can solve the problems that cannot fundamentally solve the problems of acrylic resin sticking back, the water resistance of polymer latex film, and the emulsifier is difficult to volatilize, so as to narrow the gap, Excellent aging resistance and performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

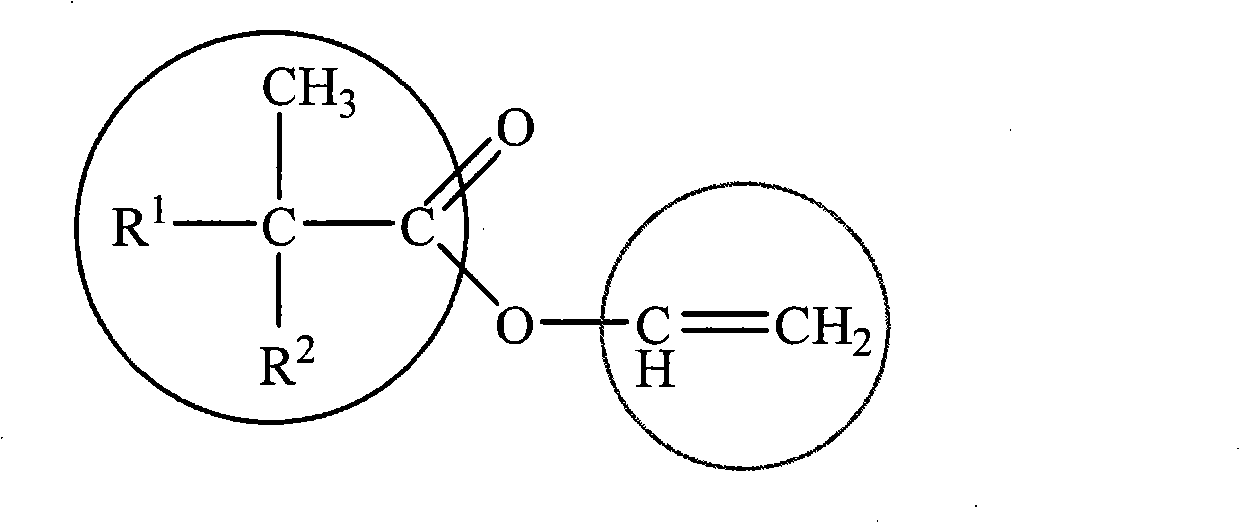

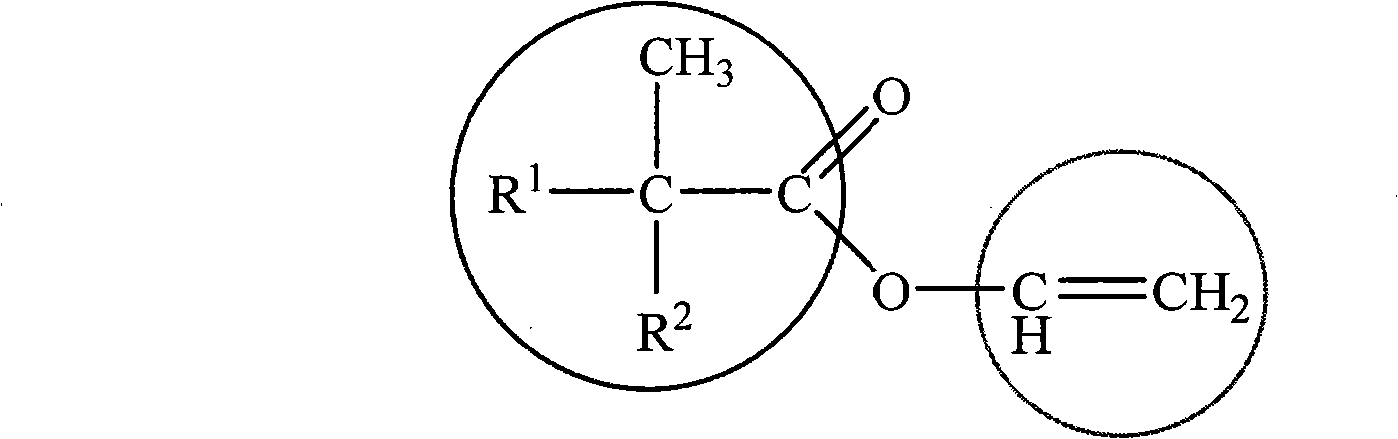

Method used

Image

Examples

Embodiment 1

[0024]Mix 68.120g of deionized water with 3.290g of allyloxy hydroxypropyl sodium sulfonate and 6.580g of methyl allyl hydroxypropyl sulfonate, stir and dissolve, then slowly add the nucleus layer monomer mixture dropwise, and pre-emulsify The core pre-emulsion was prepared in 30 minutes for later use, wherein the core layer monomer mixture was 76.520 g of methyl methacrylate, 70.520 g of hexafluorobutyl methacrylate, 56.240 g of butyl acrylate, and 52.610 g of vinyl tertiary carbonate VV-10, A mixture of N-methylolacrylamide 13.150 g. Mix 99.300g of deionized water with 1.970g of allyloxy hydroxypropyl sodium sulfonate and 3.950g of methyl allyl hydroxypropyl sulfonate, stir and dissolve, then slowly add the shell monomer mixture dropwise, and pre-emulsify The shell pre-emulsion was prepared in 30 minutes for later use, wherein the shell monomer mixture was 80.240 g of methyl methacrylate, 60.520 g of hexafluorobutyl methacrylate, 59.183 g of β-hydroxyethyl acrylate, and 112....

Embodiment 2

[0033] Mix 60g deionized water with 1.58g sodium allyloxy hydroxypropyl sulfonate and 6.310g sodium alkylamide ethylene sulfonate, stir and dissolve, then slowly add the mixture of core layer monomer and core layer monomer For: methyl methacrylate 100.27g, trifluoroethyl methacrylate 97.000g, butyl acrylate 73.950g, vinyl tertiary carbonate VV-9 44.720g, vinyltrimethoxysilane 10.150g, acrylic acid 2.630g, pre Emulsify for 30 minutes to prepare nuclear pre-emulsion for later use. Mix 80g of deionized water with 1.180g of allyloxy hydroxypropyl sodium sulfonate and 4.730g of methyl allyl hydroxypropyl sulfonate and stir to dissolve, then slowly add the shell monomer mixture solution dropwise, and the shell is single Body: 53.210g methyl methacrylate, 107.820g trifluoroethyl methacrylate, 78.912g β-hydroxyethyl methacrylate, 50.000g butyl acrylate, 50.670g vinyl tert-carbonate VV-9, acrylic acid 3.950 g, pre-emulsified for 30 minutes to prepare shell pre-emulsion for later use. ...

Embodiment 3

[0042] Mix 60g deionized water with 3.290g sodium allyloxy hydroxypropyl sulfonate and 6.580g sodium alkylamide ethylene sulfonate, stir and dissolve, then slowly add the mixed solution of the core layer monomer, the core layer monomer For: 80.270g of methyl methacrylate, 117.000g of dodecafluoroheptyl methacrylate, 160.950g of butyl acrylate, 63.870g of vinyl tert-carbonate VV-10, 2.630g of acrylic acid, pre-emulsified for 30 minutes to prepare a nuclear pre-emulsion for later use . Mix 90g of deionized water with 1.920g of allyloxy hydroxypropyl sodium sulfonate and 3.950g of methyl allyl hydroxypropyl sulfonate and stir to dissolve, then slowly add the shell monomer mixture solution dropwise, and the shell is single The body is: 95.560g of methyl methacrylate, 67.620g of dodecafluoroheptyl methacrylate, 63.220g of β-hydroxyethyl methacrylate, 61.400g of butyl acrylate, 89.670g of vinyl tertiary carbonate VV-10, 13.140 g of vinyltriisopropoxysilane and 3.950 g of acrylic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com