Preparation method of flux cored wire employing wet-mixing sintered medicinal powder

The technology of a flux-cored welding wire and a manufacturing method is applied in the manufacturing field of wet-mixed sintered powder, which can solve the problems of complex production process, high comprehensive cost, low production efficiency, etc., achieve excellent technical indicators, improve product quality, and reduce moisture absorption. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

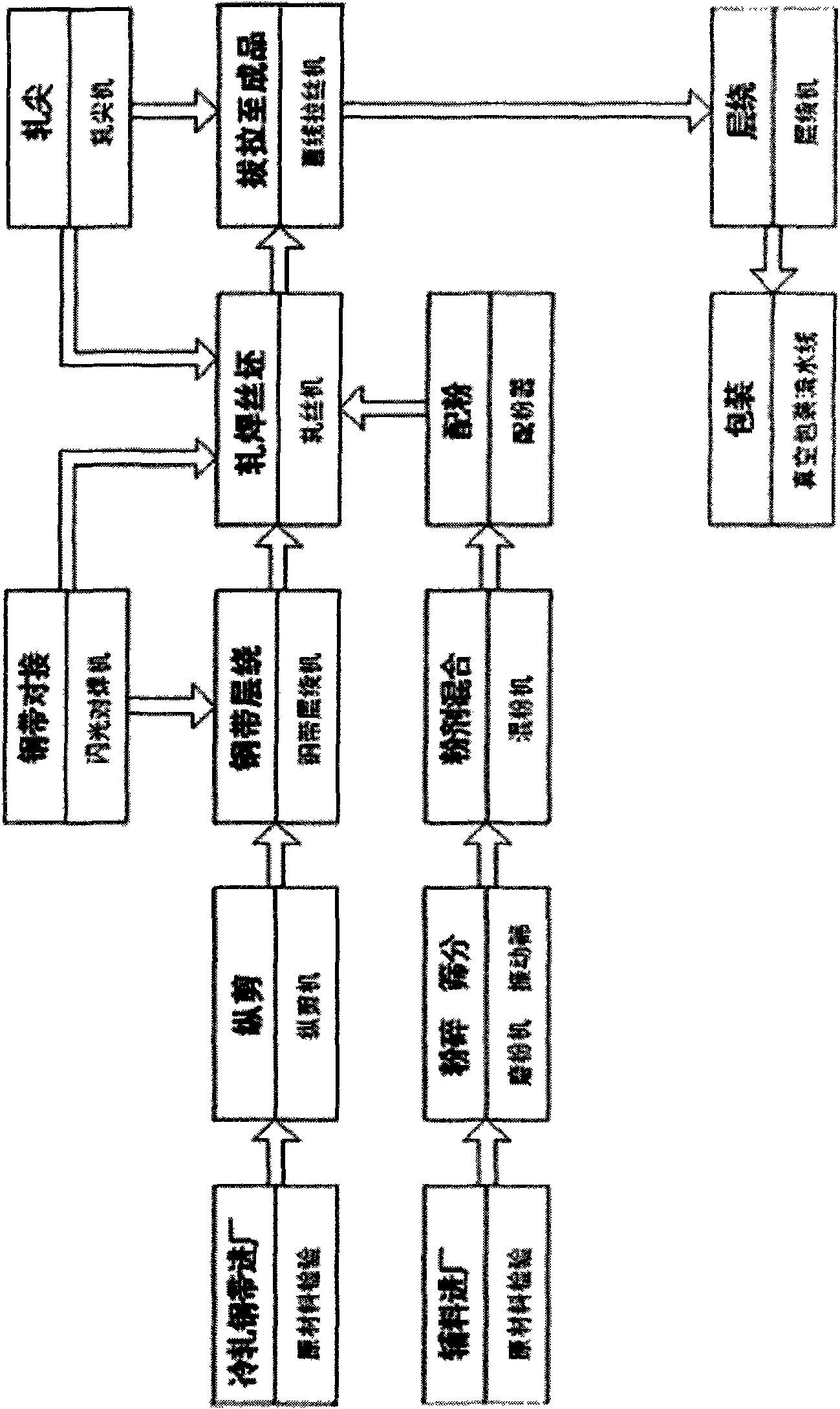

[0030] see figure 1 , with cold-rolled steel strip as the sheath raw material of flux-cored wire, with rutile and sintered powder as the main flux-cored flux, after strip slitting, powder mixing, powder drying, steel strip rolling into a "U"-shaped groove and Fill welding powder into the "U" groove, roll and close it into an "O" tube billet, and then further roll and draw it into a finished welding wire of Ф0.8-Φ2.4mm, which is characterized by the composition and content of the flux core for:

[0031] Drug core component volume ratio (%)

[0032] Rutile 40.5

[0033] Sintered powder 7

[0034] Fused magnesia 6.5

[0035] Titanium Iron 5

[0036] low manganese 6

[0037] Aluminum magnesium alloy 3

[0039] iron powder 12

[0040] Zircon sand 1.5

[0041] Boron Iron 0.5

[0044] Cryolite 1.5

[0045] Quartz 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com