Preservative treatment method for thin carbon steel plate

A technology for anti-corrosion treatment and components, applied in the plating of superimposed layers, liquid chemical plating, coatings, etc., can solve the problems of uneven thickness distribution of the coating, peeling off of the spray layer, affecting the normal use of components, etc., to strengthen anti-corrosion Treatment effect, enhanced anti-corrosion effect, good effect of nickel plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

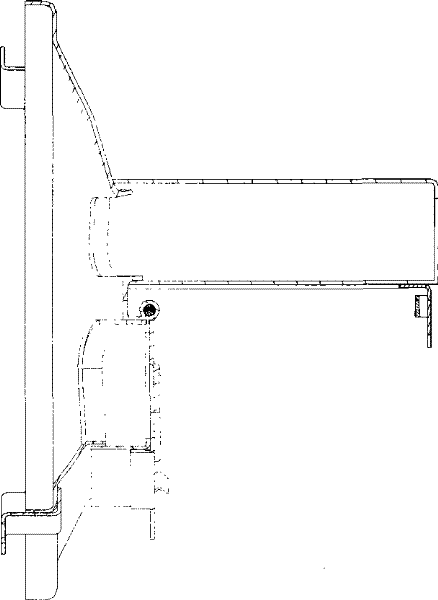

[0027] Example 1, such as figure 2 The component shown as a carbon steel sheet is a camouflaged headlight air shield, which uses Q235 sheet δ=1mm, welded structural parts, and has many bends and welds.

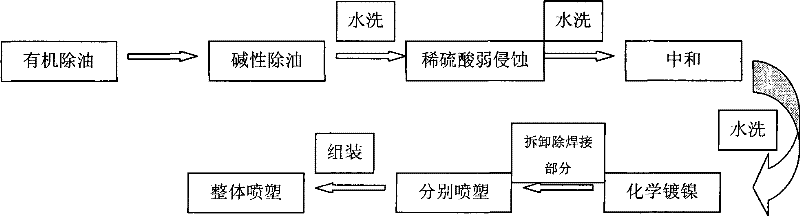

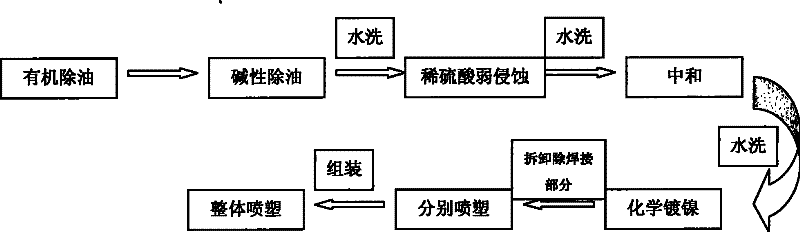

[0028] Its anticorrosion treatment method comprises the following steps:

[0029] (1) Firstly, electroless nickel plating is carried out on carbon steel sheet members:

[0030] A1. Put the camouflaged headlight air shield as a whole into organic solvent acetone to remove oil, then put it into sodium bicarbonate solution to remove oil, wash it with water, put it into dilute sulfuric acid with a mass percentage concentration of 10% for weak erosion, then wash it with water, and then Neutralize the dilute acid with sodium bicarbonate solution and rinse with clean water.

[0031] B1. Put the camouflaged headlight air shield after cleaning into the plating solution for 3 hours; the pH value of the plating solution is 6, and the thickness of the electroless nickel plating layer i...

Embodiment 2

[0043] Example 2, using Q235 thin plate welded with δ=1mm to make structural parts, there are many bends and welds.

[0044] Its anticorrosion treatment method comprises the following steps:

[0045] (1), firstly carry out electroless nickel plating on the components:

[0046] A1. Put the components that make up the components into organic solvent ethanol for degreasing, then put them into sodium carbonate solution for degreasing, put them into dilute sulfuric acid with a mass percentage concentration of 10% for weak erosion after washing with water, then wash with water, and then wash them with carbonic acid Sodium solution neutralizes dilute acid, and finally rinses with clean water;

[0047] B1. After the cleaning treatment, the components that make up the components are put into the plating solution for plating for 2 hours; the pH value of the plating solution is 5.8, and the thickness of the electroless nickel plating layer is 15 μm.

[0048] Described plating solution ...

Embodiment 3

[0059] Embodiment 3, using Q235 thin plate δ=1mm to weld to make structural parts, there are many bends and welds.

[0060] Its anticorrosion treatment method comprises the following steps:

[0061] (1), firstly carry out electroless nickel plating on the components:

[0062] A1. Put the whole component into the organic solvent acetone to degrease, then put it into a sodium hydroxide solution with a mass percentage concentration of 15% to degrease, wash it with water, put it into dilute sulfuric acid with a mass percentage concentration of 10% for weak erosion, and then wash it with water. Then use 10% sodium hydroxide solution to neutralize the dilute acid, and finally rinse with clean water;

[0063] B1. The components after the cleaning treatment are put into the plating bath as a whole and plated for 4 hours; the pH value of the plating bath is 6.2, and the thickness of the electroless nickel plating layer is 40 μm.

[0064] Described plating solution is made up of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com