Microbial compound inoculum for production of cellulosic ethanol and preparation method thereof

A technology of cellulosic ethanol and composite bacterial agents, applied in the direction of microorganism-based methods, methods using microorganisms, biochemical equipment and methods, etc., to achieve the effects of reducing production costs, alleviating energy crises, and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

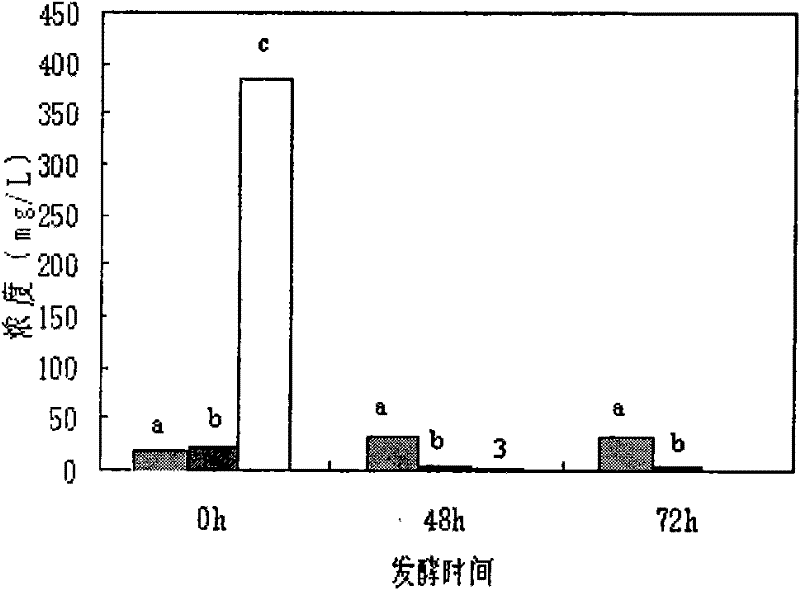

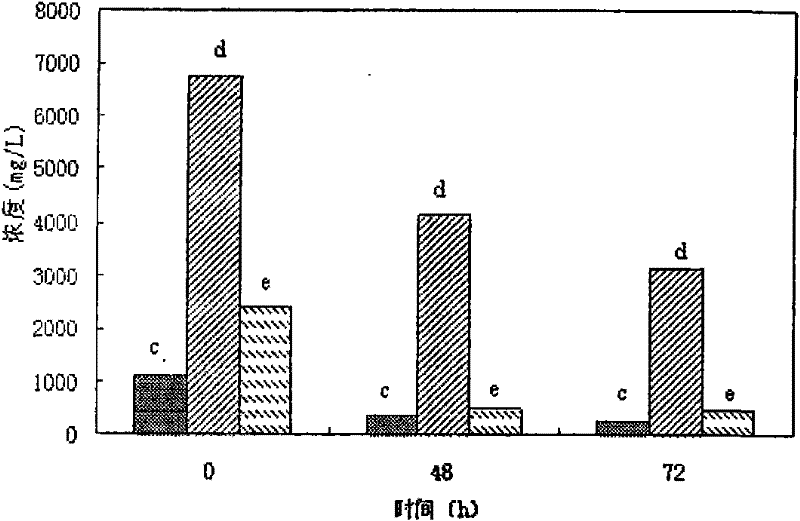

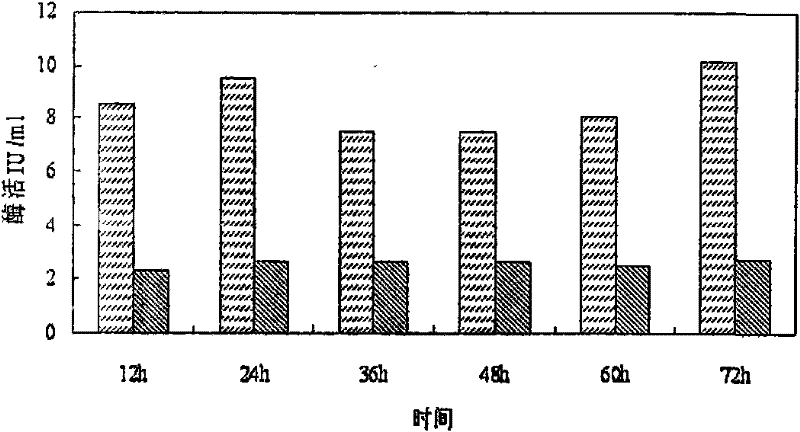

[0015] The microbial composite bacterial agent of the present embodiment reacts with formic acid, acetic acid, malic acid, hydroxymethylfurfural (HMF) and phenolic substances respectively, and the result after the reaction shows that the composite bacterial agent of the present invention formic acid, acetic acid, malic acid, hydroxyl The degradation rates of methylfurfural (HMF) and phenols were 72.37% to 81.69%, 50.61% to 60.89%, 78.18% to 89.12%, 98% to 100% and 70.08% to 86.23%. From these data, it can be seen that It can be seen that the composite bacterial agent of the present invention is used in the production process of cellulose ethanol, and has a good removal effect on formic acid, acetic acid, malic acid and phenolic compounds produced in the pretreatment process of corn stalks. The detoxification effect is good.

[0016] The steps of utilizing the microbial composite bacterial agent of the present embodiment to carry out the cellulosic ethanol production process ar...

specific Embodiment approach 2

[0023] Specific embodiment five: what this embodiment is different from specific embodiment four is that the preparation method of Trichoderma korningii spore suspension in step 1 is: Trichoderma korningii is inoculated on the slant of potato dextrose agar medium, at 28~32 ℃ of conditions Cultivate for 48-72 hours to obtain Trichoderma korningina spores, then wash the Trichoderma korningina spores obtained by culturing on the slant of potato dextrose agar medium with sterile water, and mix the sterile water and Trichoderma korningina spores evenly to obtain Trichoderma korningina spores Mold spore suspension. Other steps and parameters are the same as those in Embodiment 4.

[0024] Specific embodiment six: what this embodiment is different from specific embodiment four or five is that the preparation method of aspergillus oryzae spore suspension in step one is: aspergillus oryzae is inoculated on the slant of potato dextrose agar medium, at 28~32 ℃ of conditions Cultivate fo...

specific Embodiment approach 3

[0025] Specific embodiment seven: the difference between this embodiment and specific embodiment six is that the preparation method of Chaetomium spore suspension in step 1 is: inoculate Chaetomium on the slant of potato dextrose agar medium, in 28~32 Cultivate at ℃ for 48-72 hours to obtain Chaetomium spores, then wash the Chaetomium spores obtained by culturing on the potato dextrose agar medium slope with sterile water, and mix the sterile water and Aspergillus oryzae spores evenly. A suspension of Chaetomium spores was obtained. Other steps and parameters are the same as those in Embodiment 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com