Method and device for controlling thickness of steel wire hot-plating layer

A technology for control equipment and control methods, applied in hot dip plating process, coating, metal material coating process, etc., can solve the problems of difficult hot coating thickness, poor working conditions, air pollution, etc., to achieve easy automation, low consumption Low cost, guaranteed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

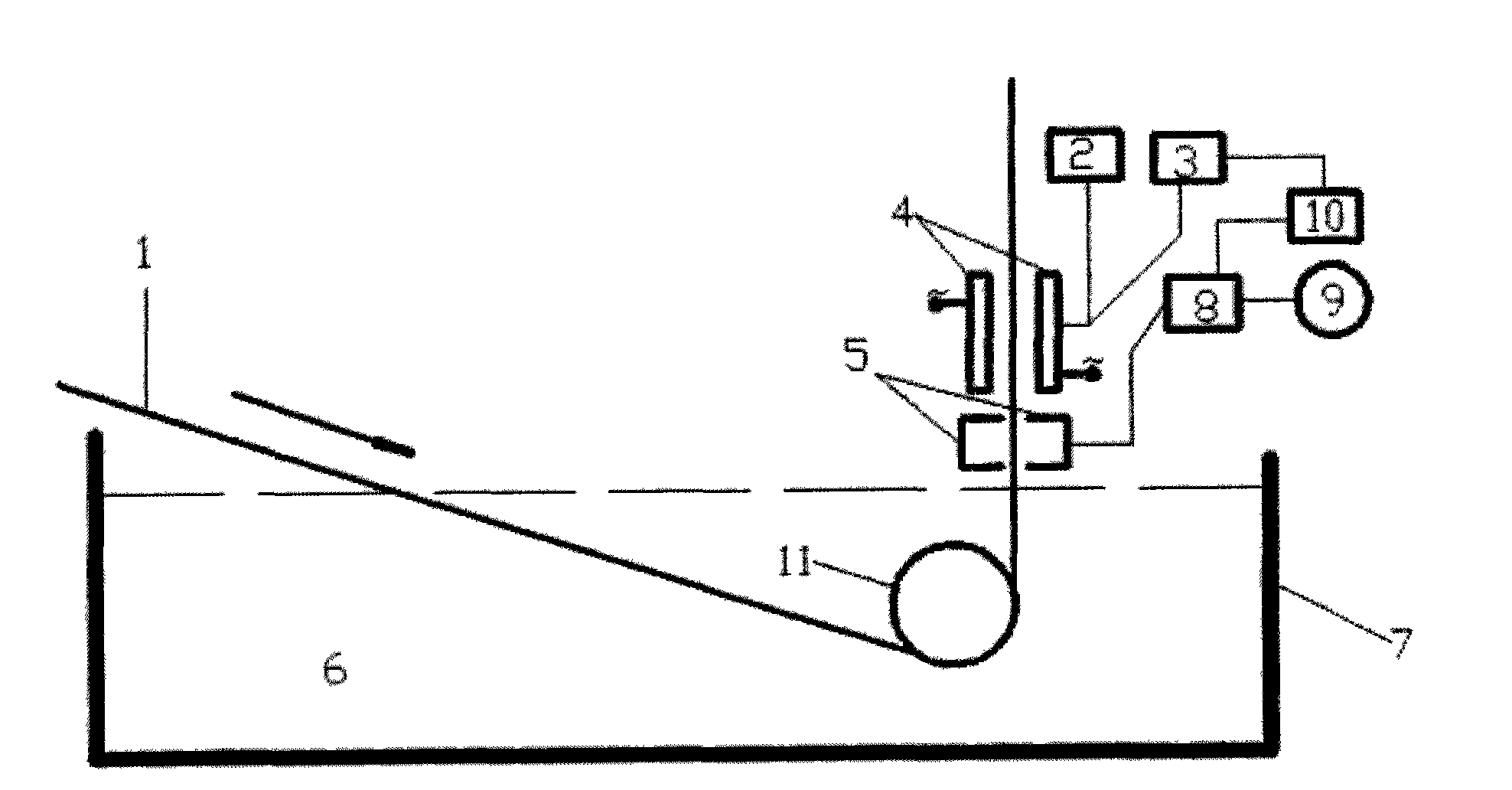

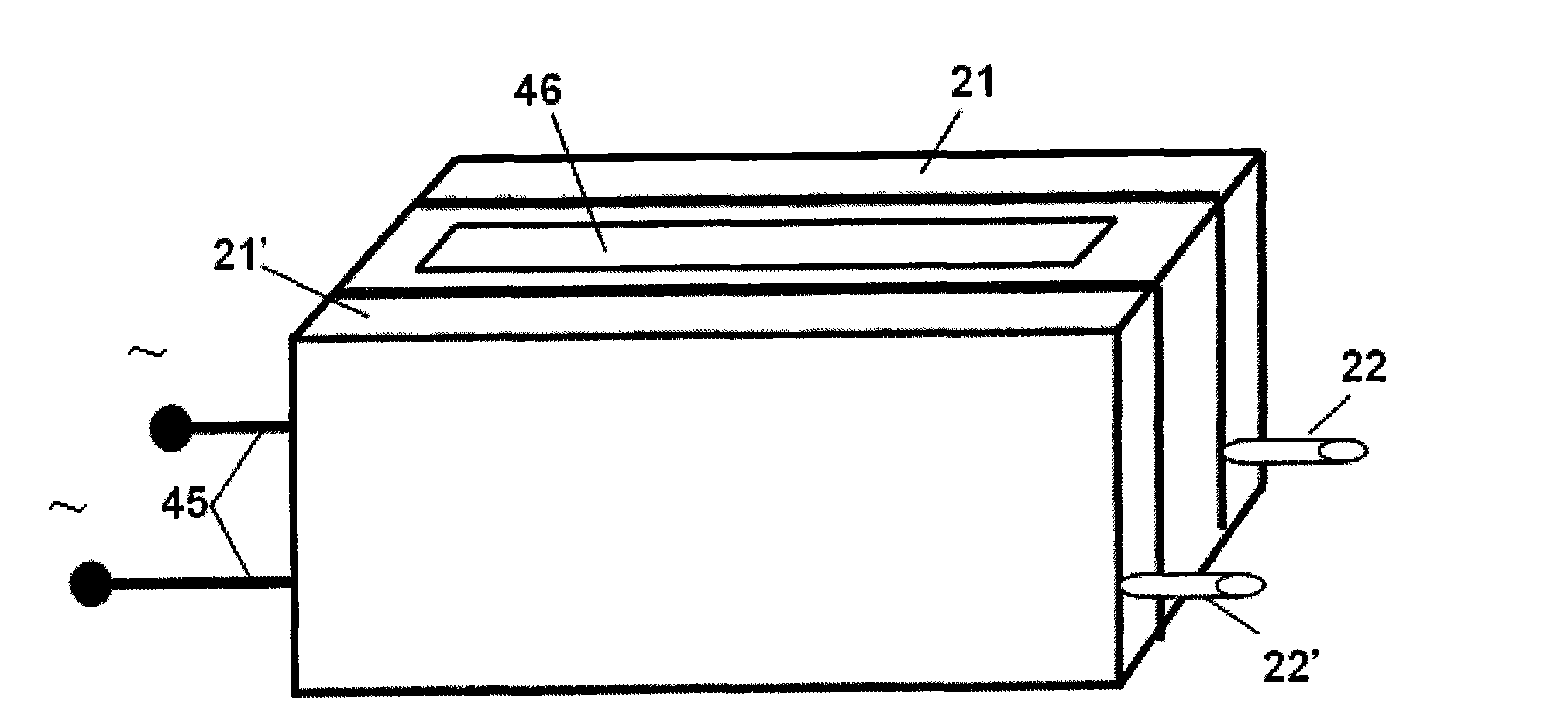

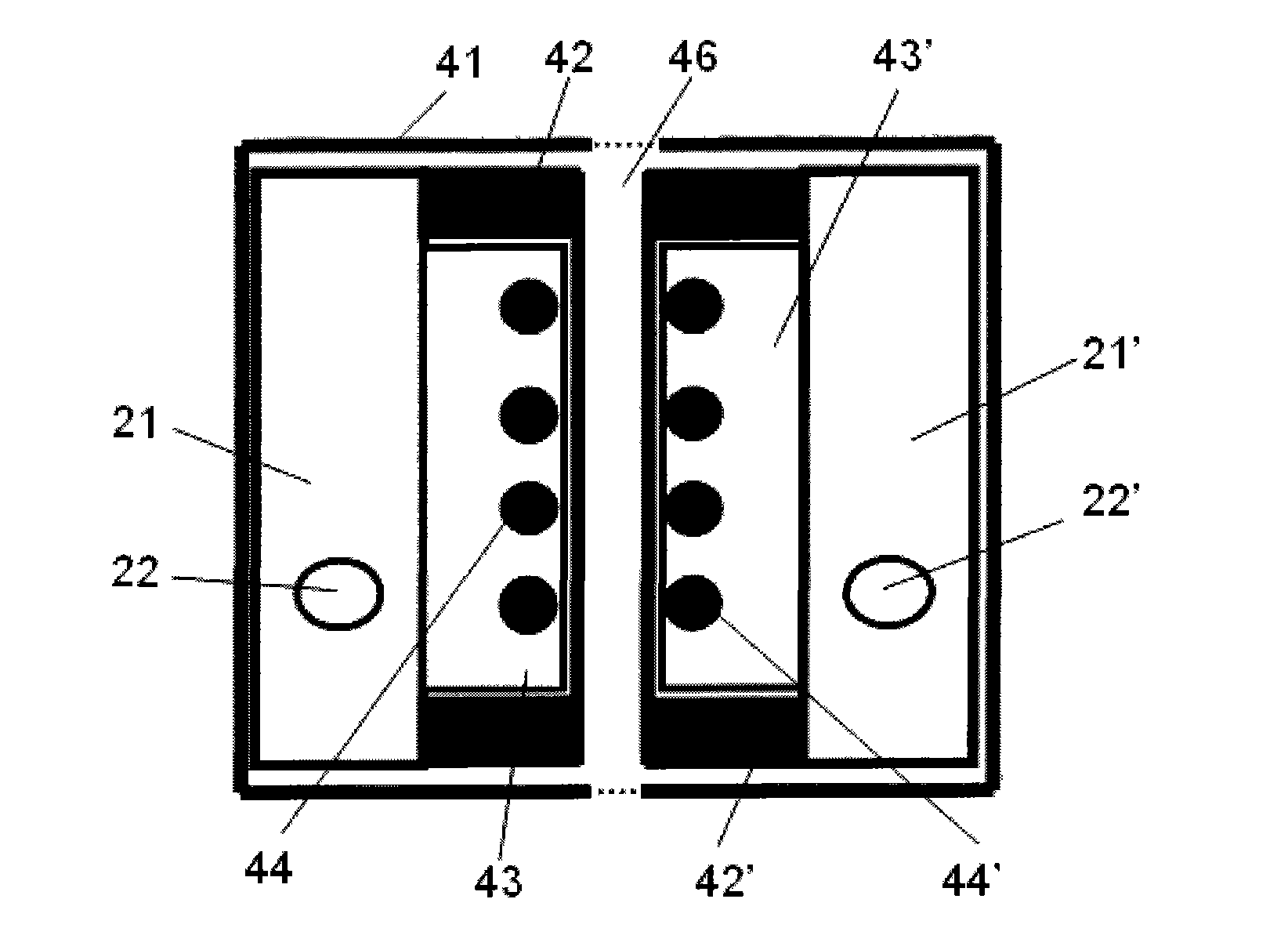

Embodiment 1

[0038] Using the method and equipment of the present invention to implement hot-dip galvanizing of steel wire with a product diameter of 1.6mm, the zinc amount is required to be 150g / m 2 . The process design is: line speed 60m / min, DV=96, wiping gas pressure ≥0.5Mpa, wiping gas flow rate 30L / min, wiping gas heating temperature 280℃; wiping electromagnetic force is 35A. The diameter of the internal electromagnetic coil of the electromagnetic wiper 4 The long oval coil made of copper tube, the electromagnetic wiper 4 cuboid structure size is 500mm×70mm×150mm, the power of the magnetic field generator 3 is 5KW, the frequency is 3KHz, the magnetic wiper 4’s magnetic field force is 35A, cycle The cooling water temperature is 20℃; the power of the gas heating box 8 is 2KW, the wiping gas pressure is ≥0.5Mpa, the wiping gas flow rate is 30L / min, and the wiping gas heating temperature is 280℃. After testing, the zinc content of the steel wire product obtained is 155g / m 2 , The thickne...

Embodiment 2

[0040] Using the method and equipment of the present invention to implement hot-dip galvanizing of steel wire with a product diameter of 6.0mm, the zinc amount is required to be 300g / m 2 . The process design is: line speed 80m / min, DV=480, wiping gas pressure 1.0Mpa, wiping gas flow rate 50L / min, wiping gas heating temperature 330℃; wiping electromagnetic force is 50A. The diameter of the internal electromagnetic coil of the electromagnetic wiper 4 of the equipment The oblong coil made of copper tube, the electromagnetic wiper 4 cuboid structure size is 500mm×70mm×150mm, the power of the magnetic field generator 3 is 5KW, the frequency is 3KHz, the magnetic wiper 4’s magnetic field force is 50A, cyclic The cooling water temperature is 20℃; the power of the gas heating box 8 is 2KW, the wiping gas pressure is 1.0Mpa, the wiping gas flow rate is 30L / min, and the wiping gas heating temperature is 330℃. After testing, the zinc content of the obtained steel wire product is 310g / m 2...

Embodiment 3-6

[0042] The method and equipment of the present invention are used to implement hot-dip galvanizing of steel wires with diameters of 2.5mm, 3.5mm, 4.0mm and 5.0mm respectively, and the required zinc amount is 250g / m respectively 2 , 280g / m 2 , 300g / m 2 And 300g / m 2 . The other process conditions are designed as follows: the line speed is 60m / min, 70m / min, 77m / min, and 80m / min, the DV value is 150, 245, 308, and 400 respectively, and the wiping gas pressure is ≥1.0Mpa. The wiping gas flow rates are 35L / min, 35L / min, 40L / min and 40L / min. The wiping gas heating temperature is between 280℃, 280℃, 330℃ and 330℃; the wiping electromagnetic force is 28A, 35A, 40A and 47A. The diameter of the internal electromagnetic coil of the electromagnetic wiper 4 of the equipment The oblong coil made of copper tube, the electromagnetic wiper 4 cuboid structure size is 500mm×70mm×150mm, the power of the magnetic field generator 3 is 5KW, the frequency is 3KHz, the magnetic wiper 4’s magnetic force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com