Static-driven tunable optical filter based on optical waveguide and F-P cavity and manufacturing method thereof

An electrostatic drive and optical filter technology, which is applied to optical waveguides, optics, instruments, etc., can solve the problems of complex manufacturing process, unfavorable optical device integration, increased coupling and packaging difficulty, etc., and achieves wide tuning range, compact and novel structure. , the effect of reducing light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

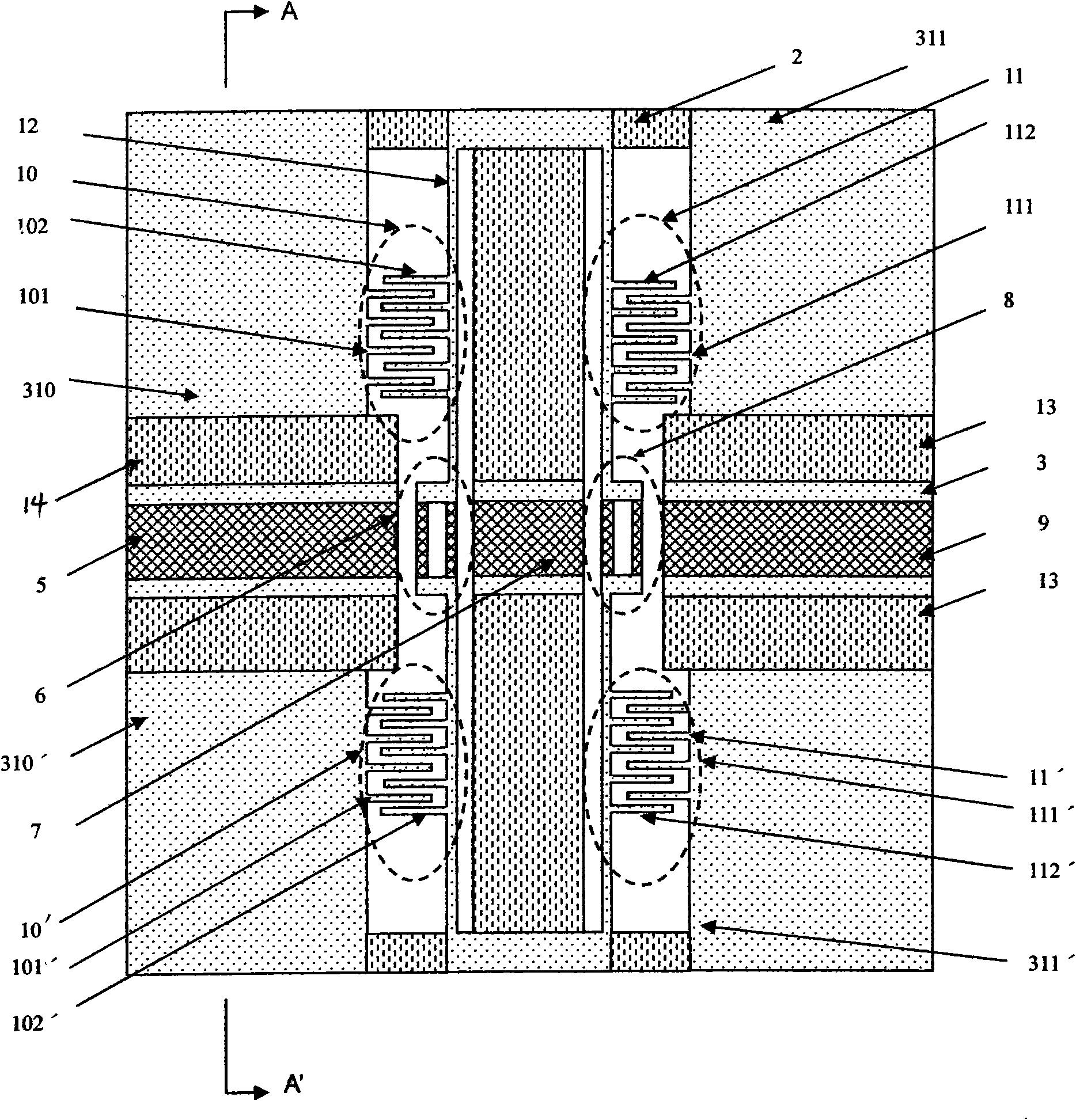

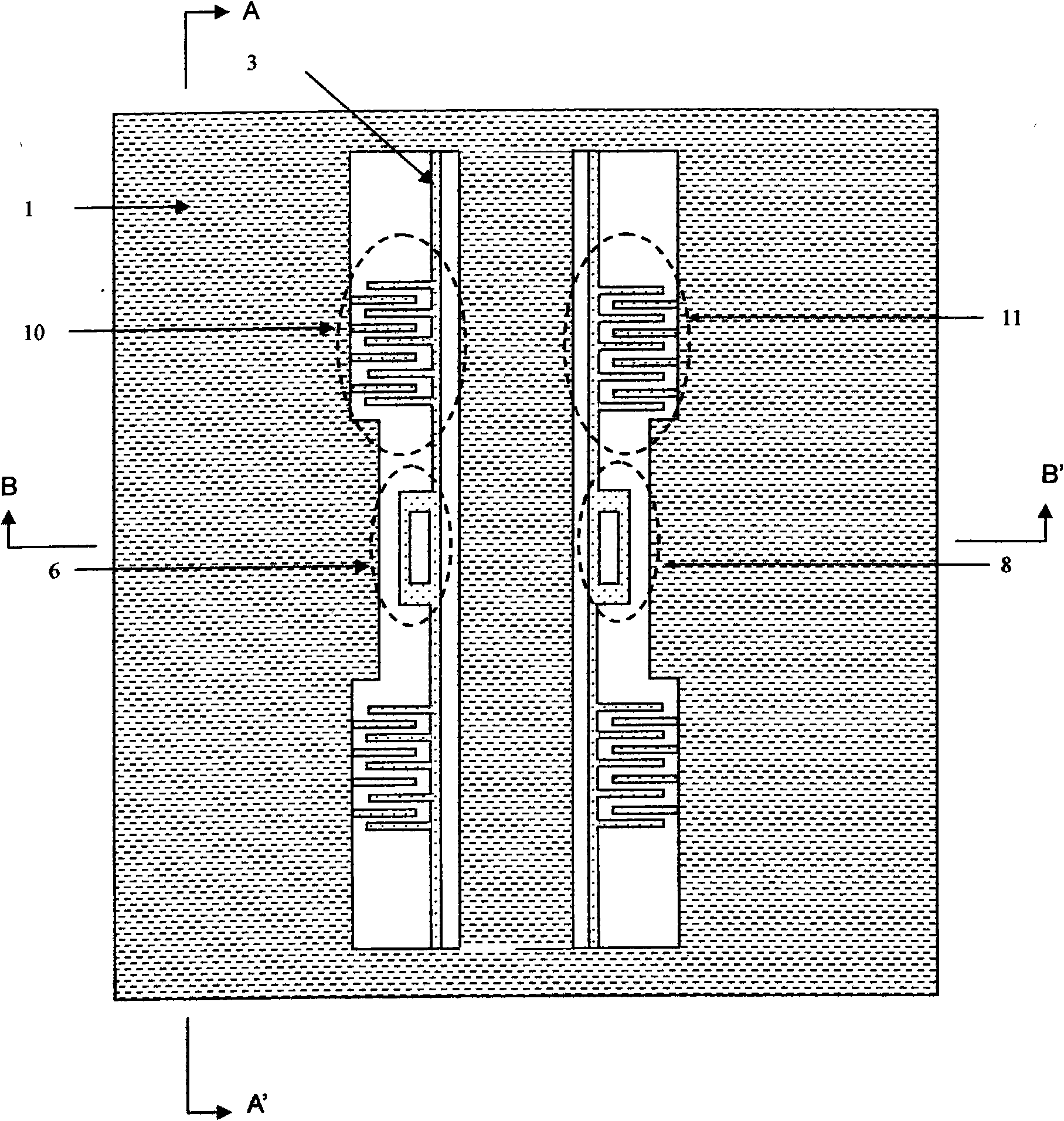

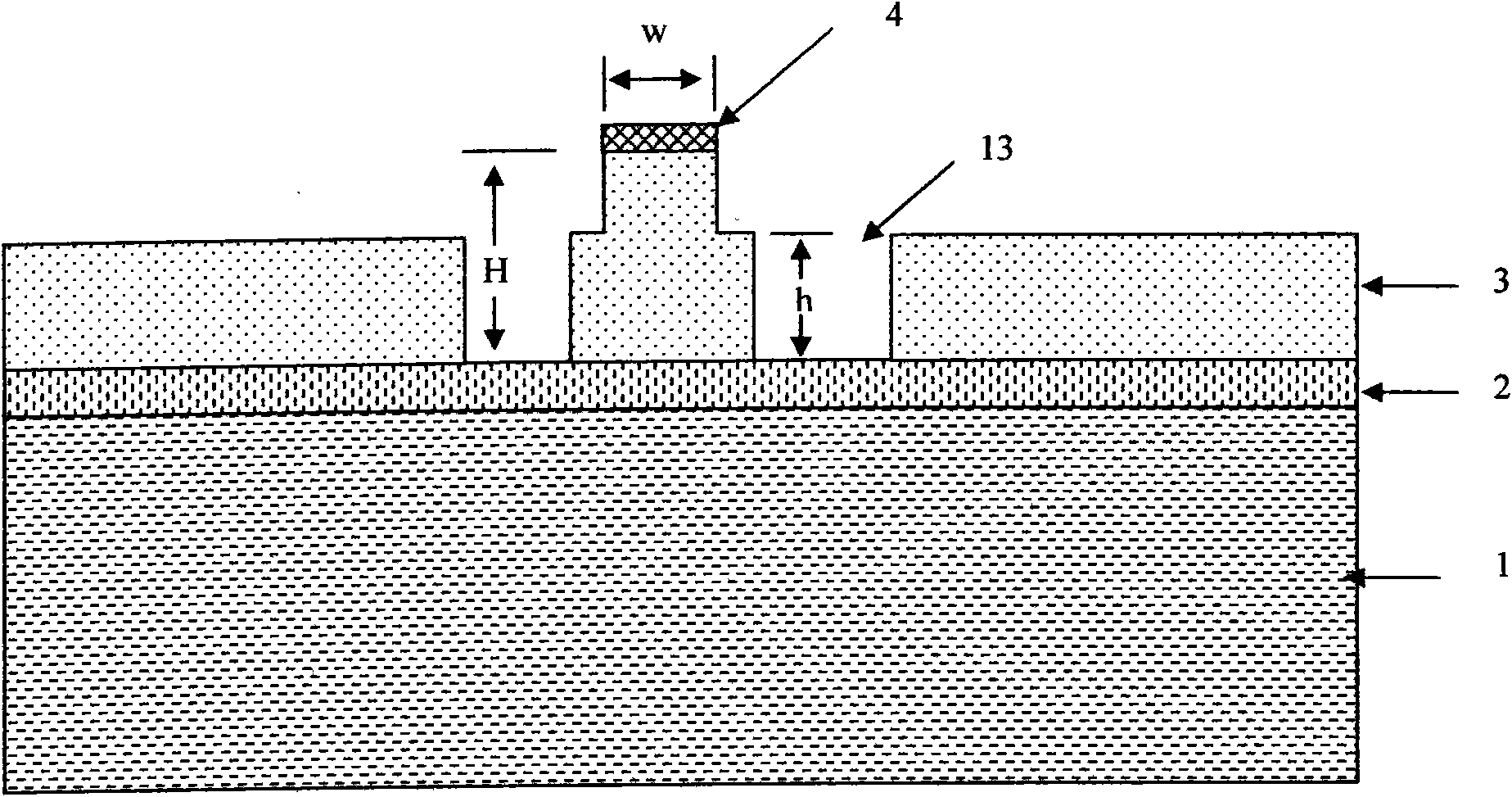

[0050] To achieve continuous tunability within the wavelength range of 1530nm to 1560nm (consistent with the spectral width of the erbium-doped fiber amplifier), the dimensions of the DBR and F-P cavities are as follows: the silicon / air gap is 2 and a half, that is, air / silicon / air / silicon / air structure, the width of the air gap is 1.9 microns, the width of the silicon is 0.5 microns; the width of the silicon waveguide F-P cavity is 5 microns. The height of the DBR is thin-layer SiO 2 and the height of both the top layer silicon and the height of the F-P cavity is thin layer SiO 2 and the height of the SOI substrate and .

[0051] The parameters of the comb electrode: the number of pairs of comb teeth is 20 pairs, the length of the comb teeth is 15 microns, the width is 5 microns, the height is 10 microns, the gap between the movable teeth and the fixed teeth is 2 microns, the overlapping length is 13 microns, The spacing is 3 microns. An elastic straight beam is used, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com