Implantable material for medical or surgical application

A technology of xyloglucan and implant material, which is applied in the directions of packaging, packaged food, medicine packaging, etc., can solve problems such as complication, and achieve the effect of avoiding the loss of fiber structure and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

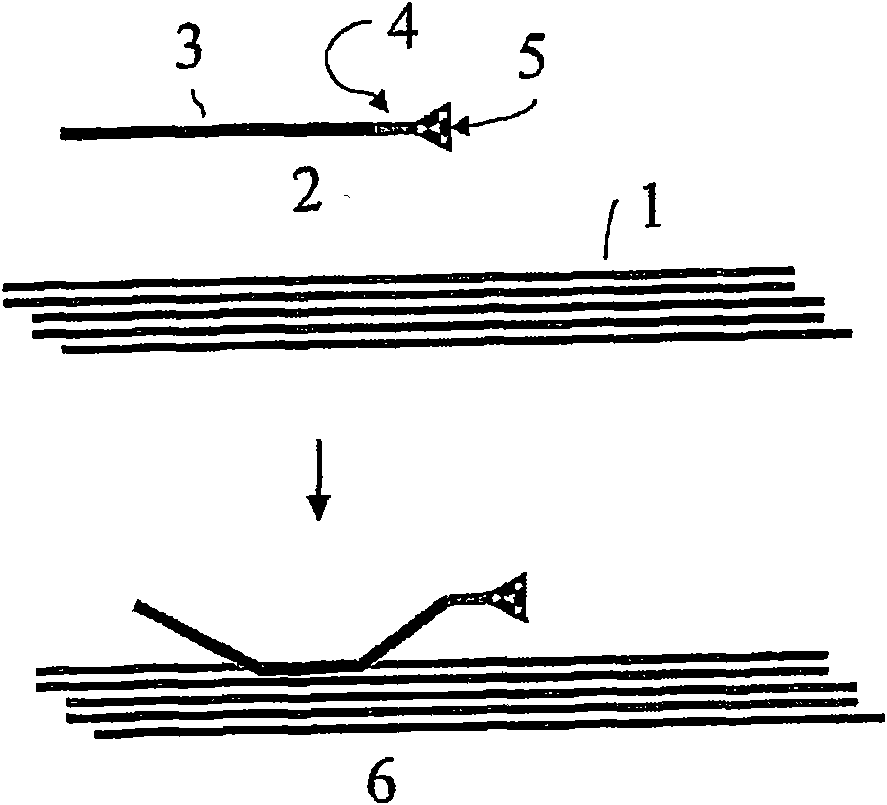

[0121] The present inventors modified the surface of bacterial cellulose with xyloglucan-GRGDS conjugates, and analyzed the effect of GRGDS-modified bacterial cellulose on endothelial cell adhesion.

[0122] Material

[0123] Bacterial cellulose (BC) hydrogel and Whatmann filter paper (grade 1, made of pure cotton linter for comparison) were investigated in Congo red and xyloglucan adsorption studies. Trimethylsilylcellulose (TMSC) was used in adsorption studies using QCM. The TMSC was synthesized as described in Kontturi et al., Langmuir 19 (2003) 5735-5741. Using Roux flasks (100 mL working volume), BC were statically grown in corn steep liquor for three days at 30°C to produce a 2 mm pellicle. The strain used for this biosynthesis was Acetobacter xylinum subsp. sucrofermentas BPR2001, article number: 1700178 TM . This strain was purchased from American Type Culture Collection. By boiling at 60°C in 0.1M NaOH for 4 hours, followed by millipore TM The water is repeate...

Embodiment l

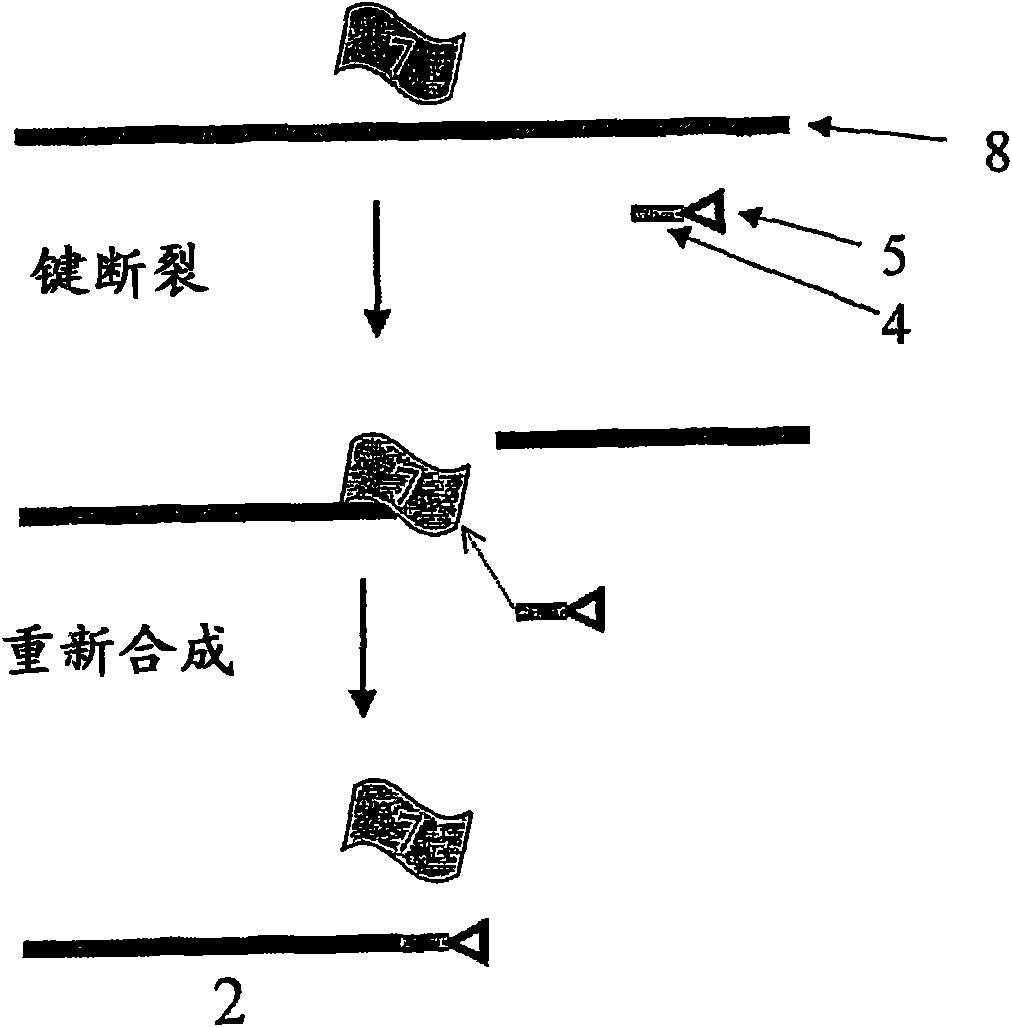

[0125] Preparation of xyloglucan and xyloglucan-GRGDS

[0126]Tamarind kernel flour (60% xyloglucan content , D.N.Palani, Mumbai, India), thus obtaining a mixture of XXXG, XLXG, XXLG and XLLG xyloglucan oligosaccharides (XGO) (15:7:32:46). The XGO was activated via conversion of 1-deoxy-1-amino-β-glycoside to the corresponding 1-deoxy-1-aminosuccinamic acid salt derivative (XGO-succ) as follows. XGO (1 g, 0.78 mmol) was dissolved in deionized water (10 mL), then ammonium bicarbonate (2.5 g) was added, and the mixture was then incubated at 42 °C while continuously adding ammonium bicarbonate to maintain saturation. Stir for 28 hours. The progress of the reaction was monitored by TLC (70 / 30 acetonitrile / water). Excess ammonium bicarbonate was removed by three freeze-drying cycles to yield a white powder consisting of a mixture of XGO and 1-deoxy-l-amino-β-glycoside; based on anomeric protons from starting materials and products 1 Integrating the H-NMR signal, the degree of...

Embodiment 2

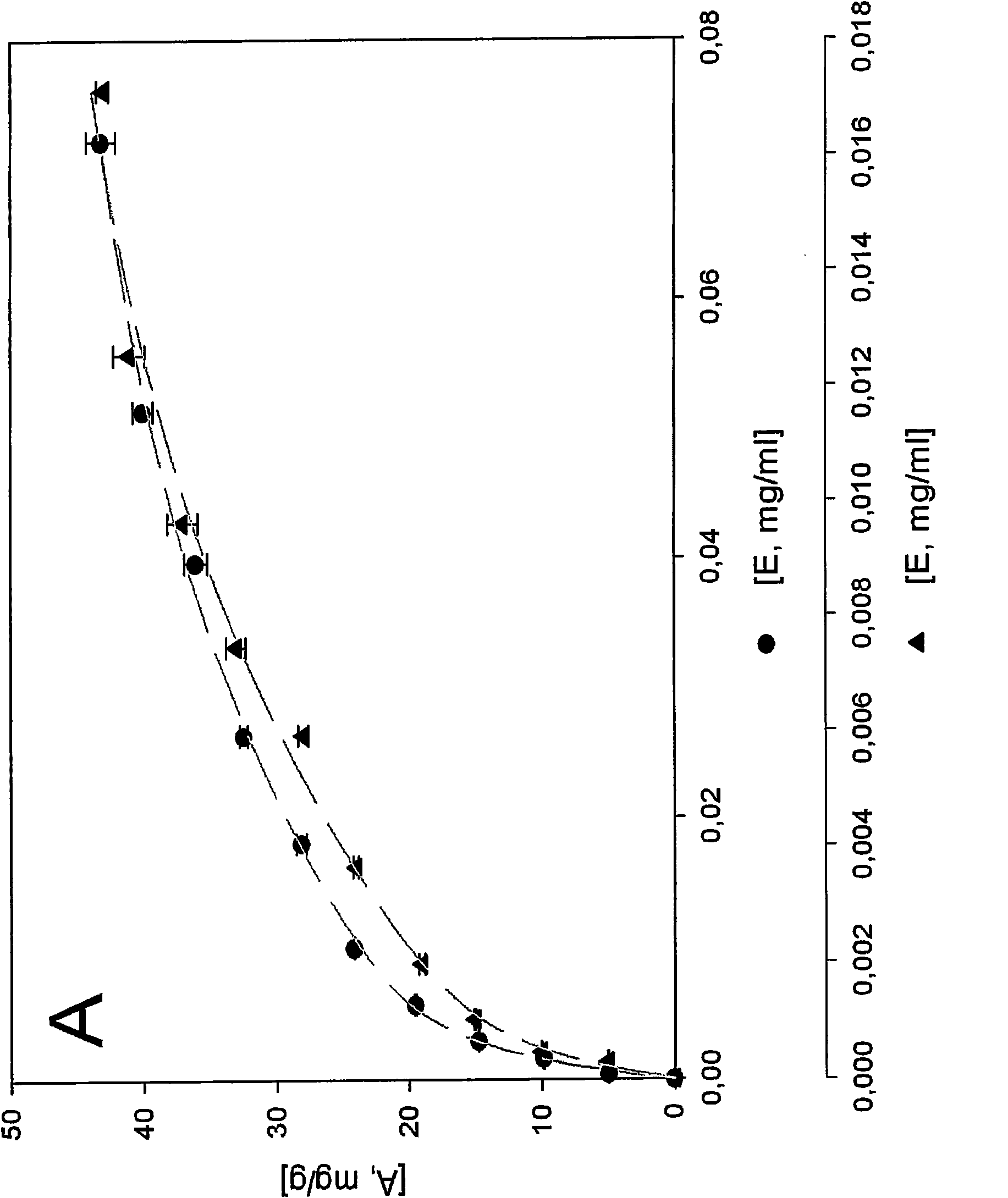

[0133] Adsorption of Congo Red

[0134] By measuring Congo red dye (Direct Red 28, purchased from Riedel-de Germany) maximum adsorption capacity to evaluate the specific surface area of bacterial cellulose and cotton as a reference. Six sheets of Whatman No. 1 paper and six bacterial cellulose gels were used at each adsorption concentration. The cellulosic material was exposed to Congo red in 4 ml of aqueous solution containing 0.5, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0 (w / w) Congo red, and at 60° C. at 100: 1 liquid ratio to stain for 24 hours. NaCl (20% w / w) was added as electrolyte. The residual concentration of Congo red [E, mg / ml] was calculated from the UV absorbance at 492 nm using the standard curve. The adsorption amount [A, mg / g] of Congo red on the fiber was calculated by dividing the adsorption difference of the solution at 492 nm before and after the binding reaction by the fiber mass per volume of the solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com