Tio2 nanostructures, membranes and films, and methods of making same

A nanostructure, nanofiber technology, used in nanostructure fabrication, chemical instruments and methods, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

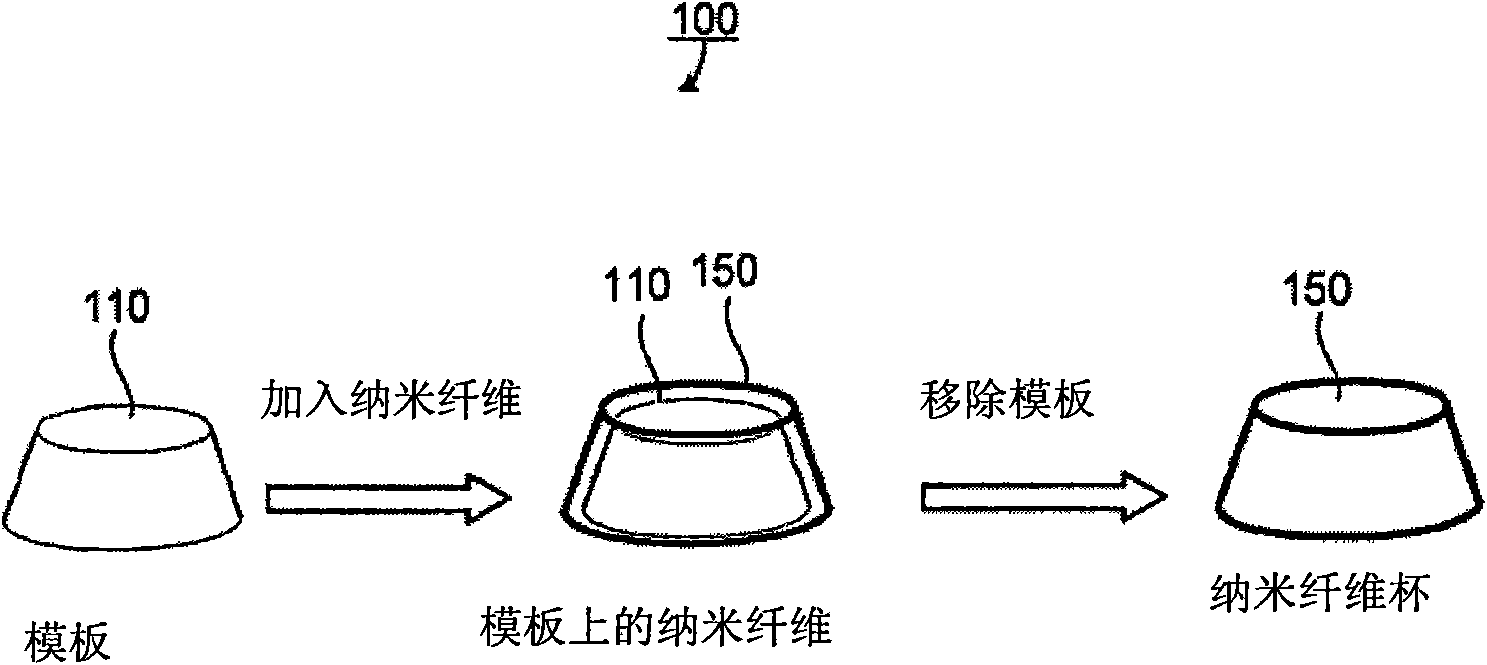

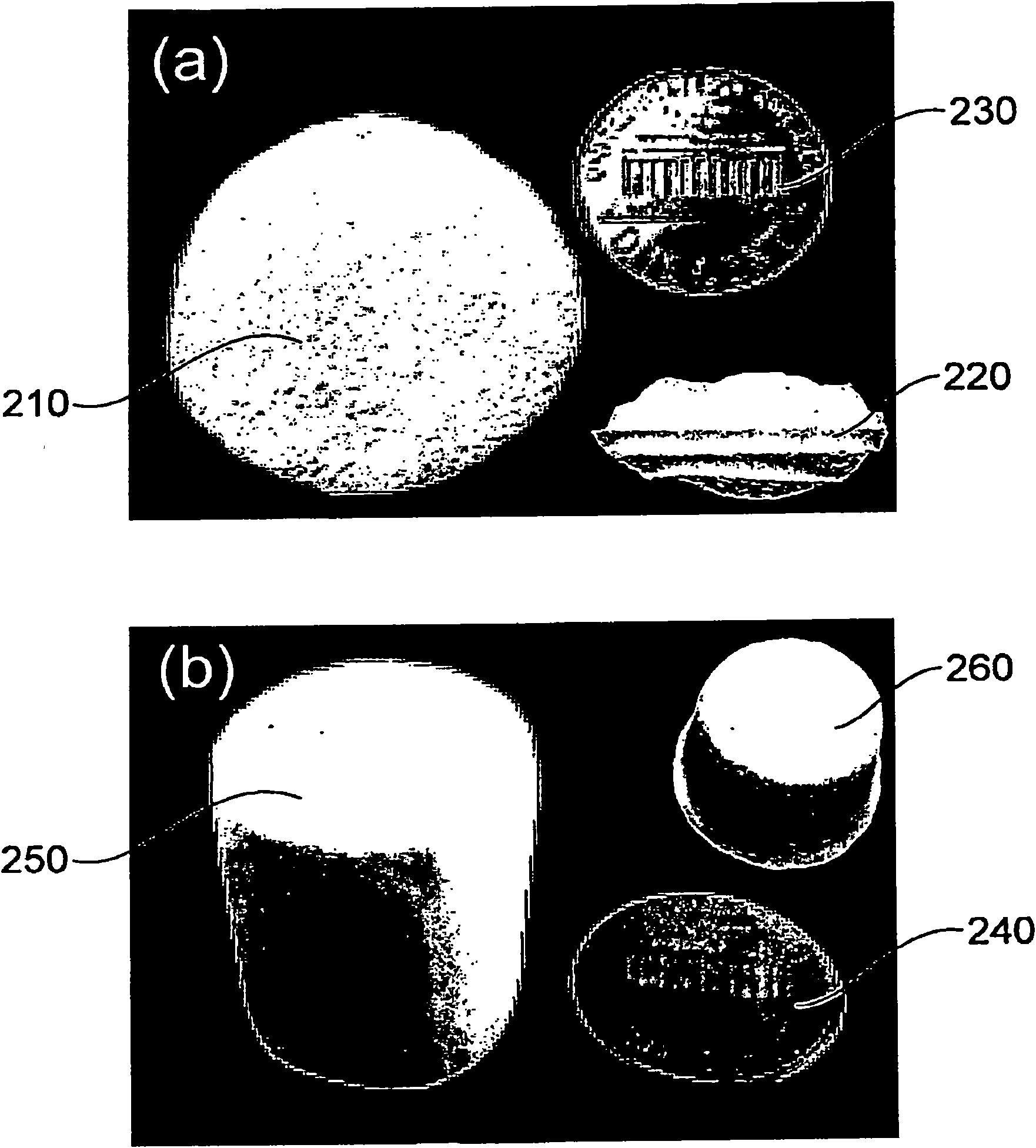

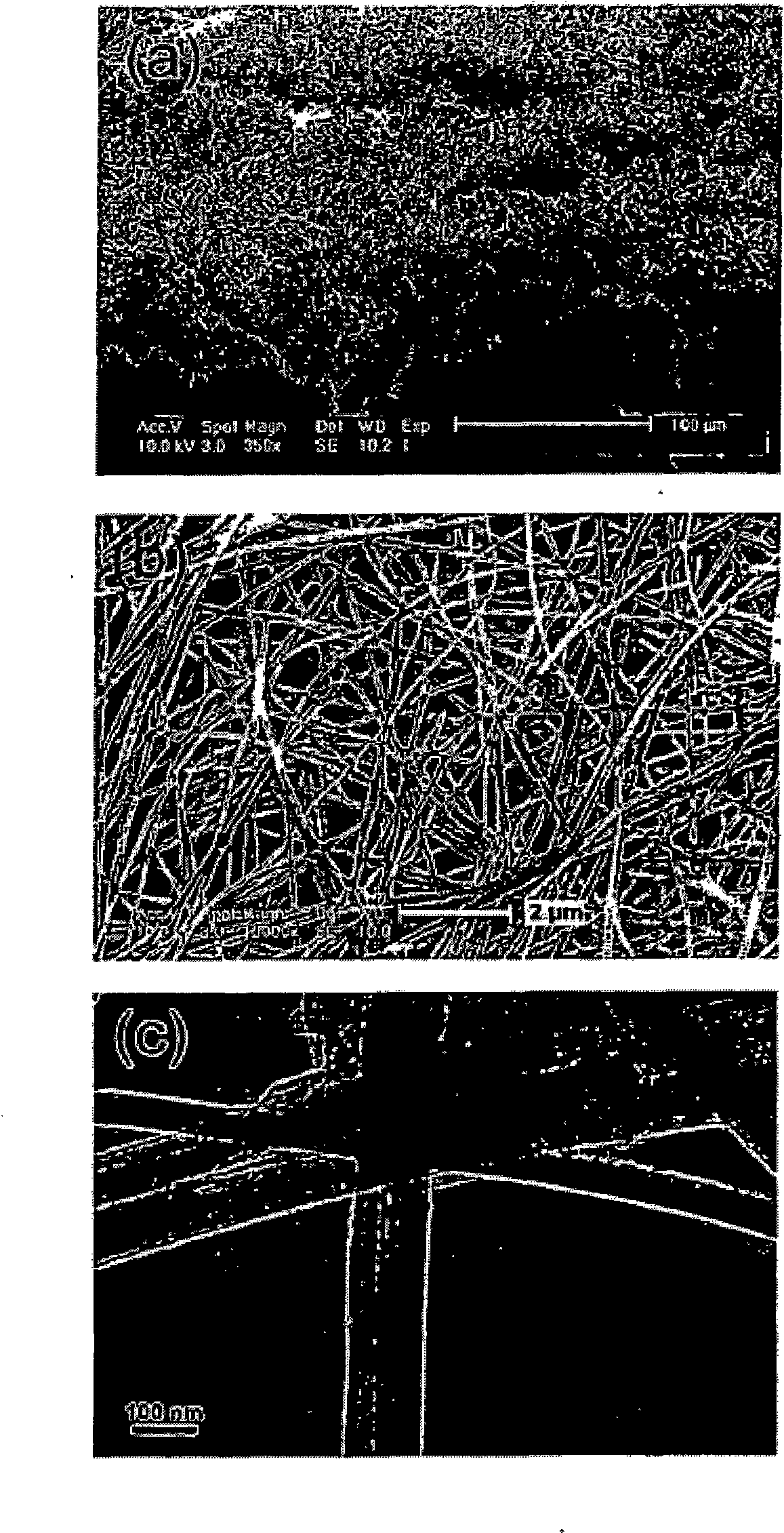

[0105] Synthetic TiO 2 Large-scale nanofibers / nanowires and fabrication of FSM and 3D devices: According to the present invention, a TiO-containing 2 Synthesis of large-scale nanofibers / nanowires.

[0106] In this typical example, about 0.3 g TiO 2 The powder (Degussa P25) was added to 40ml of 10M alkali metal or alkaline solution, and these mixtures were placed in a Teflon-lined autoclave container with a capacity of 150ml. The container was sealed and placed in an oven to heat for 7 days. Collect the white slurry containing TiO 2 The large-size nanofiber products were washed with distilled water or dilute acid. The washed white slurry containing TiO 2 The product of large-size nanofibers was cast on a macroscopic template (made of ashless filter paper (Watman) or polyethylene film), followed by drying at RT. The cast-in-drying process was repeated several times at RT, followed by heating in an oven (heating temperature 0-180° C.) for about 0.5-30 hours. Thus, using th...

Embodiment 2

[0121] Contains TiO 2 The immediate application of large-scale nanofibers is to provide write-erase-rewrite functionality for information storage with the help of UV irradiation. TiO 2 Often used as an inexpensive and non-toxic photocatalyst. After being excited by UV rays, TiO 2 Can catalyze dye degradation [25].

[0122] In this example, 4 characters "UARK" of hydrated ink (1.0 x 1 mol / L crystal violet) was written to the TiO-containing 2 The large size nanofibers were fabricated on FSM paper 610. The FSM paper 610 having the written information of "UARK" was exposed to UV rays in the air. After 15 minutes of exposure to UV rays, the 4 characters "UARK" disappear, as Image 6 as shown in b. In this example, the write-erase cycle can be repeated 4 times on the FSM paper 610 (21.4 mg). After exposure to UV rays, all 4 characters "UARK" are erased every time, as in Image 6 as shown in b. However, for regular printing paper 620 (49.0 mg), each UV irradiation resulted ...

Embodiment 3

[0125] Contains TiO 2 Another application of large-size nanofibers is photocatalysis. It has been confirmed that TiO 2 The photocatalytic activity of -B phase is superior to other TiO 2 Phase [27]. These robust nanowire-based membrane catalysts are unique in the photocatalytic decomposition of organic pollutants due to their large pore size properties [15]. Such as Nerve Agent Analogs (NAS) [15], for example, (C2H5O)2P(O)(H2CSC6H5) (Aldrich).

[0126] In a typical embodiment, the TiO-containing 2 10mg FSM made of large size nanofibers was soaked in about 10mL 1mol / L Mg(NO 3 ) 2 12 hours. The impregnated FSM was dried at RT, followed by heating above 100°C in air for about 3 hours. The heated FSM is then placed into a solution containing various organic contaminants. In this example, the organic contaminants include NAS. A UV lamp (Entella, type B100AP / R) was set at 5 mm above the solution to irradiate the FSM with UV. Adopt UV visible spectrometer (such as HP (Hewle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com