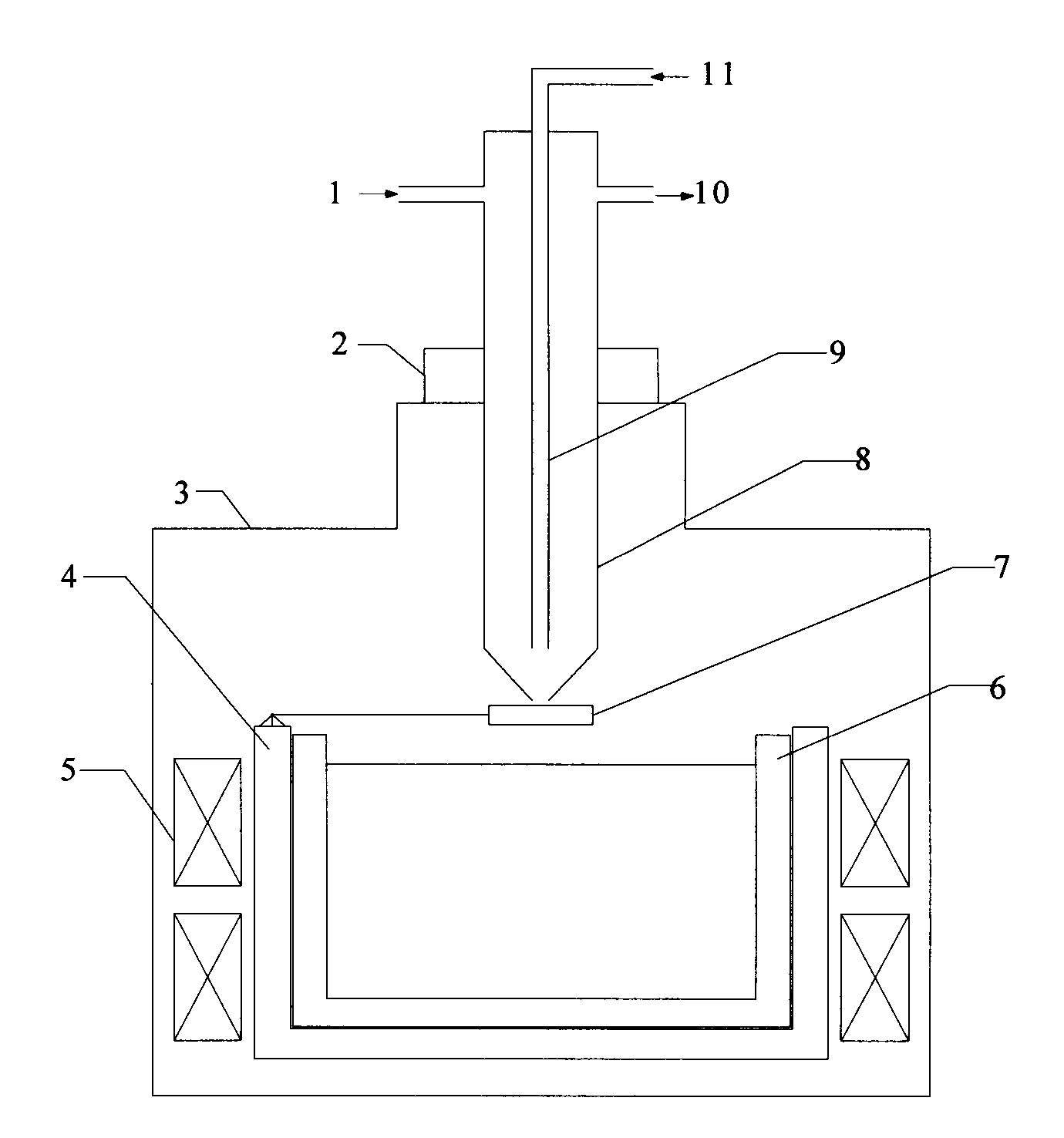

Production technology and device for boron-removing and purification of polysilicon by adopting electromagnetic induction melting assisted with high-temperature plasma

A technology of high-temperature plasma and production technology, which is applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems that the B removal effect is difficult to reach solar-grade polysilicon, complex equipment, and expensive costs, etc., so as to facilitate industrialization and reduce Energy consumption, the effect of solving the problem of arc ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1) Weigh 50 kg of raw metal silicon with a B concentration of 8 ppmw.

[0054] 2) Put the raw metal silicon into the high-strength graphite crucible, start the mechanical rotary vane pump to vacuum, when the vacuum reaches 500Pa, switch on the intermediate frequency induction coil power supply, the power is 50kw, until the silicon is completely melted.

[0055] 3) Increase the power of the intermediate frequency power supply to 60kw, make the temperature of the silicon liquid reach 1600°C, start the plasma melting system, and pass in 99.5% Ar + 0.5% H 2 O, the ventilation flow is 25L / min.

[0056] 4) Turn the arc ignition device parallel to the high-strength graphite crucible, and lower the plasma gun to a position 40mm above the arc ignition device, adjust the given voltage to 180V, and start the arc ignition. After the arc ignition is completed, rotate the arc ignition device 90-180 degrees in parallel to make it leave the surface of the silicon liquid.

[0057] 5) Adjust the...

Embodiment 2

[0060] The process is the same as in Example 1. After the silicon is completely melted, increase the power of the intermediate frequency power supply to 70kw, make the temperature of the silicon liquid reach 1700℃, and pass in 98.75% Ar+1.25% H 2 O, adjust the given current to 360A, the plasma power to 64kw, adjust the plasma arc length to 170mm, and perform plasma melting on the surface of the silicon liquid for 30 minutes. The silicon liquid was poured into a graphite mold for casting, left to stand, and the silicon ingot was taken out after cooling. The B content in the polycrystalline silicon ingot was measured by a secondary ion mass spectrometer (SIMS) to be 0.07 ppmw.

Embodiment 3

[0062] The process is the same as in Example 1. After the silicon is completely melted, increase the power of the intermediate frequency power supply to 80kw, make the temperature of the silicon liquid reach 1800℃, and pass in 99% Ar+1% H 2 O, adjust the given current to 525A, the plasma power to 92kw, adjust the plasma arc length to 320mm, and perform plasma smelting on the surface of the silicon liquid for 20 minutes. The silicon liquid was poured into a graphite mold for casting, left to stand, and the silicon ingot was taken out after cooling. The B content in the polycrystalline silicon ingot was measured by a secondary ion mass spectrometer (SIMS) to be 0.99 ppmw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com