Method for improving fermentation speed of starchy raw material alcohol and liquor yield by using xylanase

A technology of starchy raw materials and xylanase, which is applied in the field of wine making, can solve the problems of low yield of raw materials, high viscosity of fermented mash, and slow fermentation speed, and achieve the effects of increasing fermentation speed, increasing alcohol concentration, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

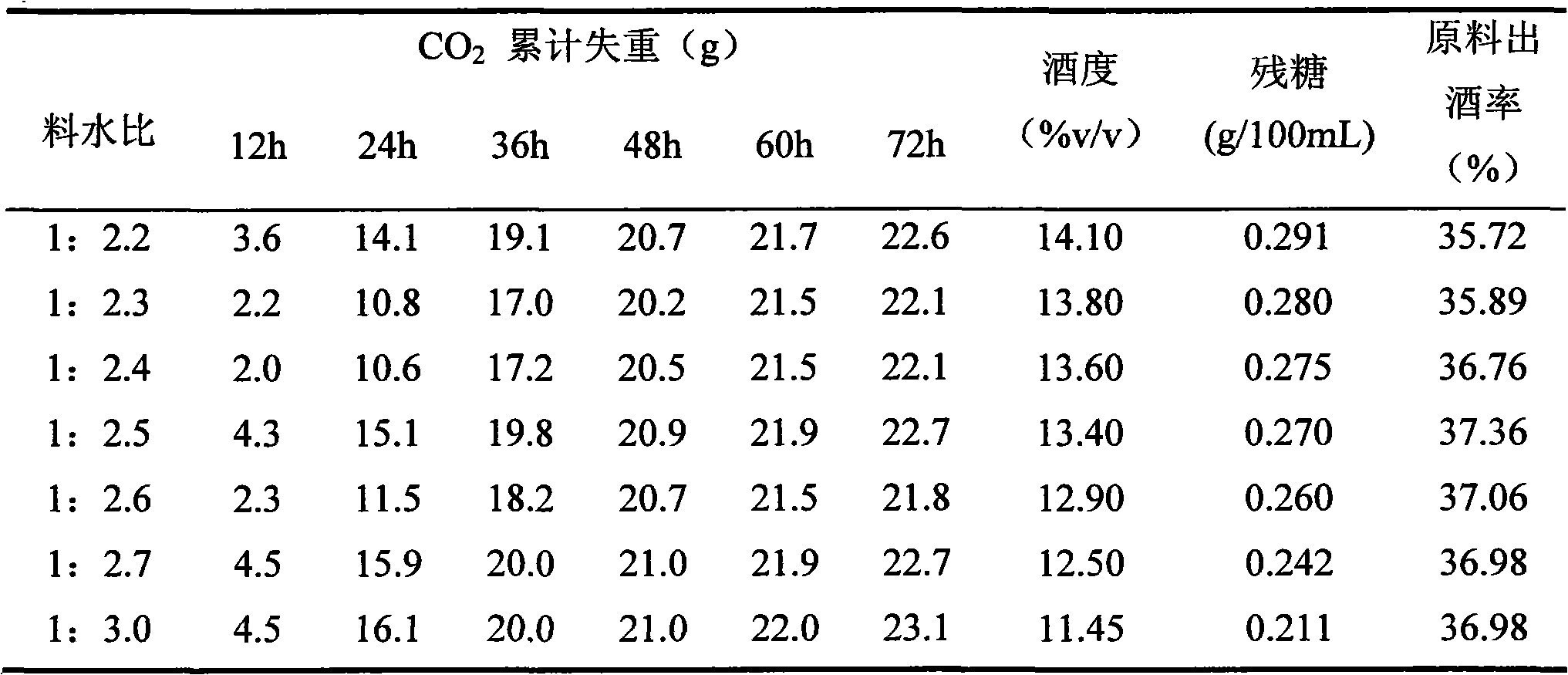

[0021] Embodiment 1: the influence of culture medium water ratio

[0022] For corn raw materials, the amount of xylanase added is 150U / g, the pH value is the natural pH, and xylanase in the addition group is added before inoculation. Adjust the water mass ratio of each group of culture medium to 1:2.2, 1:2.3, 1:2.4, 1:2.5, 1:2.6, 1:2.7, 1:3.0 for the test (other unlisted conditions and processes can refer to In the above embodiment). Each bottle was inoculated with 10% of AY-15 yeast culture seeds, and cultured in a 30°C incubator for 72 hours, and three parallel experiments were carried out for each group of material-water ratio. CO was measured every 12 hours of fermentation 2 weightlessness. After the fermentation, the alcohol concentration and residual sugar were measured respectively, and the yield of ethanol to raw materials was calculated. The experimental results are shown in Table 1. From the results, the wine yield of raw materials is the highest when the ratio o...

Embodiment 2

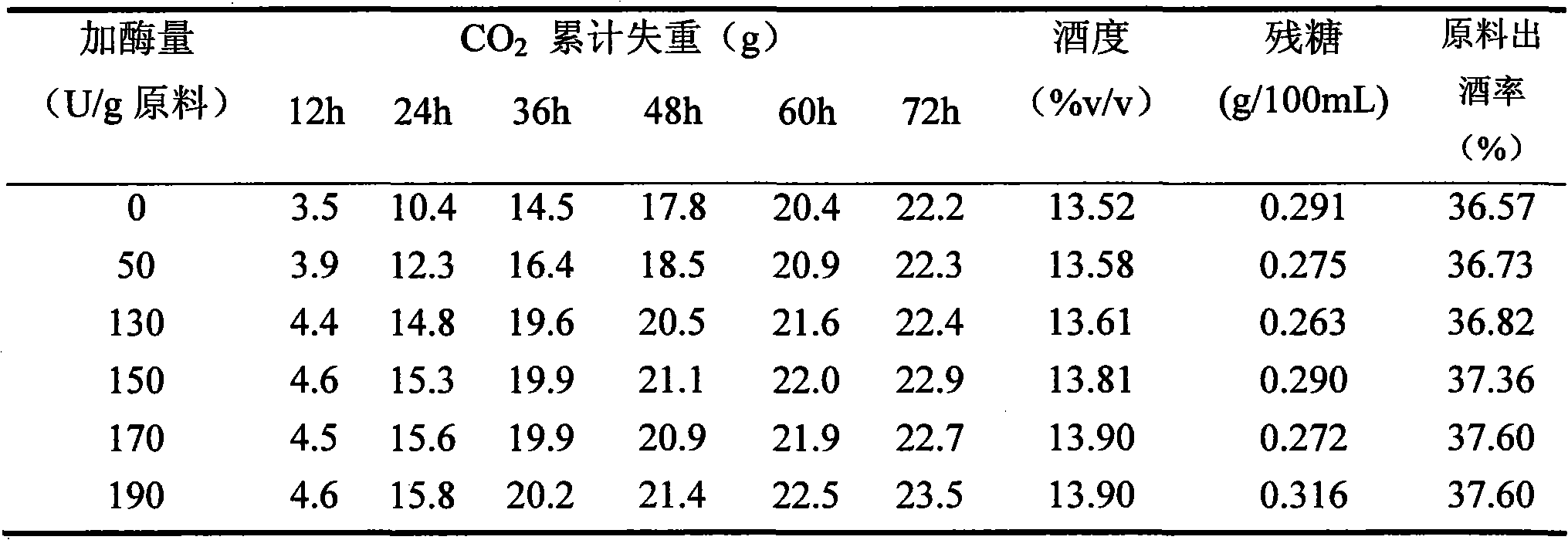

[0026] Embodiment 2: the influence of xylanase addition amount

[0027] Corn raw materials, the ratio of medium to water is 1.:2.5, the pH value is the natural pH, xylanase is added during the saccharification process, and the amount of xylanase added to each group of medium is 50U / g, 130U / g, respectively. 150U / g, 170U / g, 190U / g raw materials and no xylanase were used as controls. Each bottle was inoculated with 10% of AY-15 yeast cultured seeds, placed in a 30°C incubator for static culture for 72 hours, and three parallel experiments were performed on the amount added in each group. CO was measured every 12 hours of fermentation 2 weightlessness. After the fermentation, the alcohol concentration and residual sugar were measured respectively, and the yield of ethanol to the raw materials was calculated. The experimental results are shown in Table 2. Compared with the control group, after adding different amounts of xylanase, the alcohol content of fermented mash increased ...

Embodiment 3

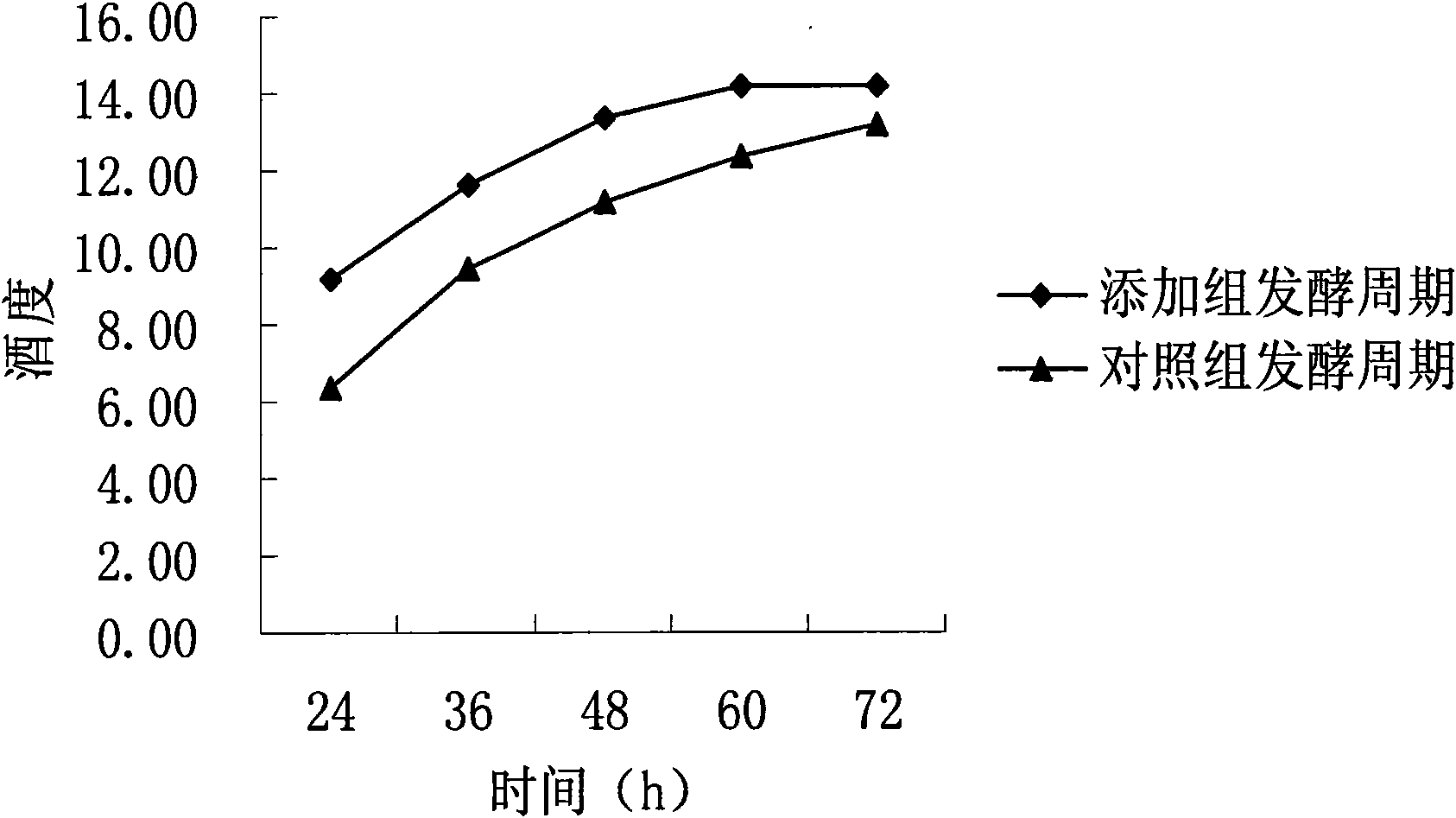

[0030] Embodiment 3: Add the impact of xylanase on fermentation cycle

[0031] For corn raw materials, the amount of xylanase added is 170U / g, the pH value is the natural pH, the ratio of material to water is 1:2.5, and the xylanase in the added group is added 6 hours after fermentation. Each bottle was inoculated with 10% of AY-15 yeast cultured seeds, cultured in a 30°C incubator, and five time periods of 24h, 36h, 48h, 60h, and 72h were selected to measure the alcohol content of the fermented mash of the control group and the added group. Three parallel experiments were done in each group, and the experimental results are shown in figure 1 . It can be known by comparison that in the whole fermentation process, the fermentation efficiency of the addition group is obviously faster than that of the control group. When the fermentation time was 60h, the alcohol content reached the maximum value, and then tended to be parallel. Compared with the control group, the fermentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com