Fibers for decontamination of chemical and biological agents

A fiber and reagent technology, applied in the field of fibers, can solve the problems of exponential decline, metal oxide particles cannot be confined to the filter tank, and cannot function as an antidote, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1-preparation of the airgel method of magnesium oxide nanoparticles

[0070] Magnesium methoxide was prepared by stirring magnesium and methanol (Merck & Co. Inc., New Jersey) at room temperature in the presence of nitrogen to form an inert atmosphere. After stirring overnight, the gel was autoclaved to 250°C at a heating rate of 1°C / min and held at this temperature for 15 minutes. The resulting white powder was further heated using a modified method. The powder was placed in a porcelain crucible and heated from room temperature to 220°C at a rate of 1°C / min and maintained at 220°C for 5 hours. The autoclave temperature was again increased from 220°C to 400°C at a rate of 1°C / min and maintained at this temperature for 4 hours. The surface area of the as-synthesized MgO material was determined to be 155m by the BET method 2 / g, which is lower than the reported surface area (Utamapanya et al., Chem. Mater., 3, 175-181) (400m 2 / g).

Embodiment 2

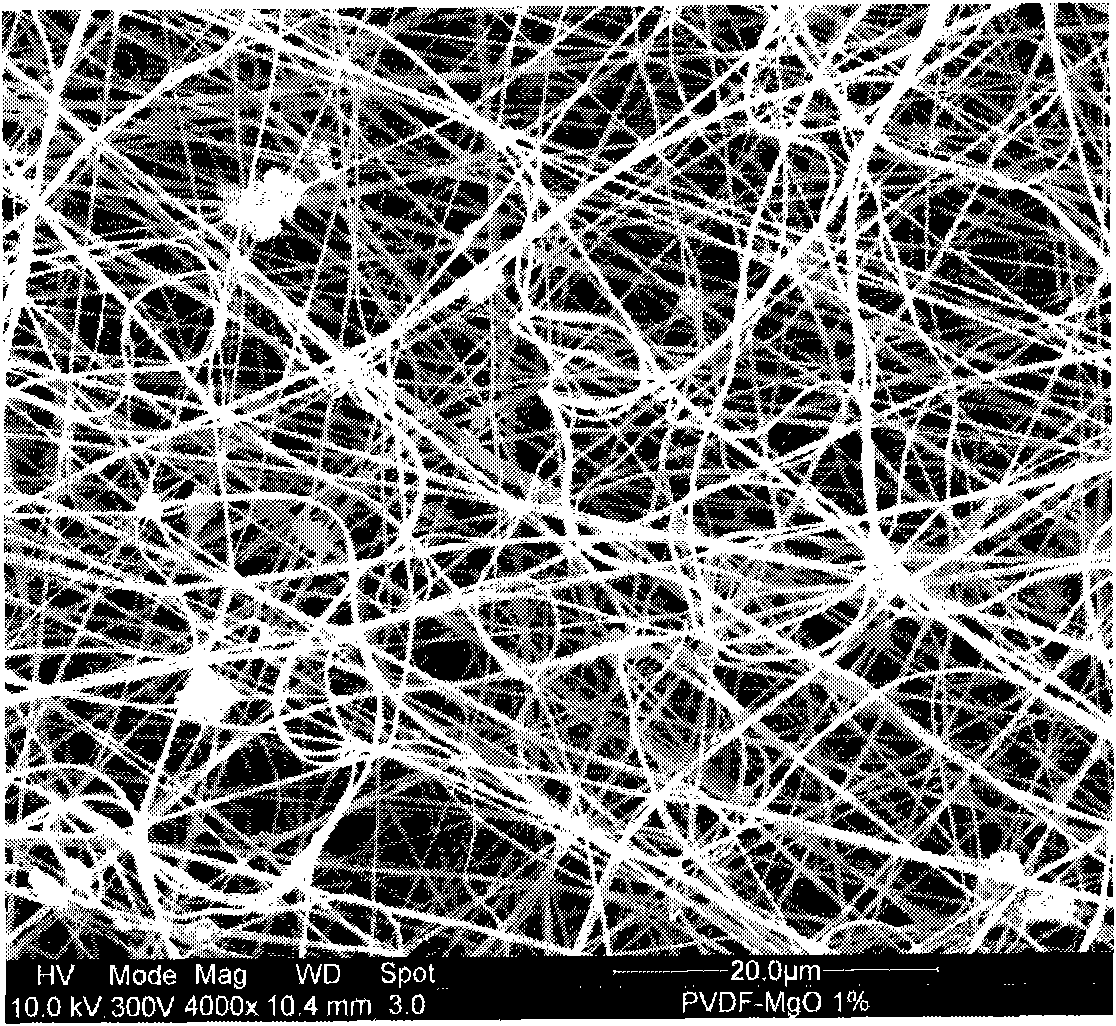

[0071] Example 2 - Method for preparing nanoscale polymer fibers with embedded metal oxide nanoparticles

[0072] with different MgO nanoparticles (or Al 2 o 3 Nanoparticles) weight-loaded polymer solutions of polysulfone polymer (PSU), poly[(difluoroethylene)-co-(hexafluoropropylene)] (PVDF copolymer), poly(vinyl chloride) (PVC) through Different amounts of MgO nanoparticles (or Al 2 o 3 nanoparticles) mixed with a polymer solution. Commercially available nano-Al 2 o 3 was purchased from Aldrich, and after sieving the material, the surface area determined by the BET method was 280 m 2 / g.

[0073] The PSU, PVDF copolymer and PVC polymer used in the experiments had number average molecular weights (M n ).

[0074] A representative method used to prepare PSU electrospun membranes is provided here. 2 g of polymer and 8 g of dimethylformamide (DMF) were magnetically stirred at room temperature for about 12 hours to dissolve the polymer. After the polymer was completely...

Embodiment 3

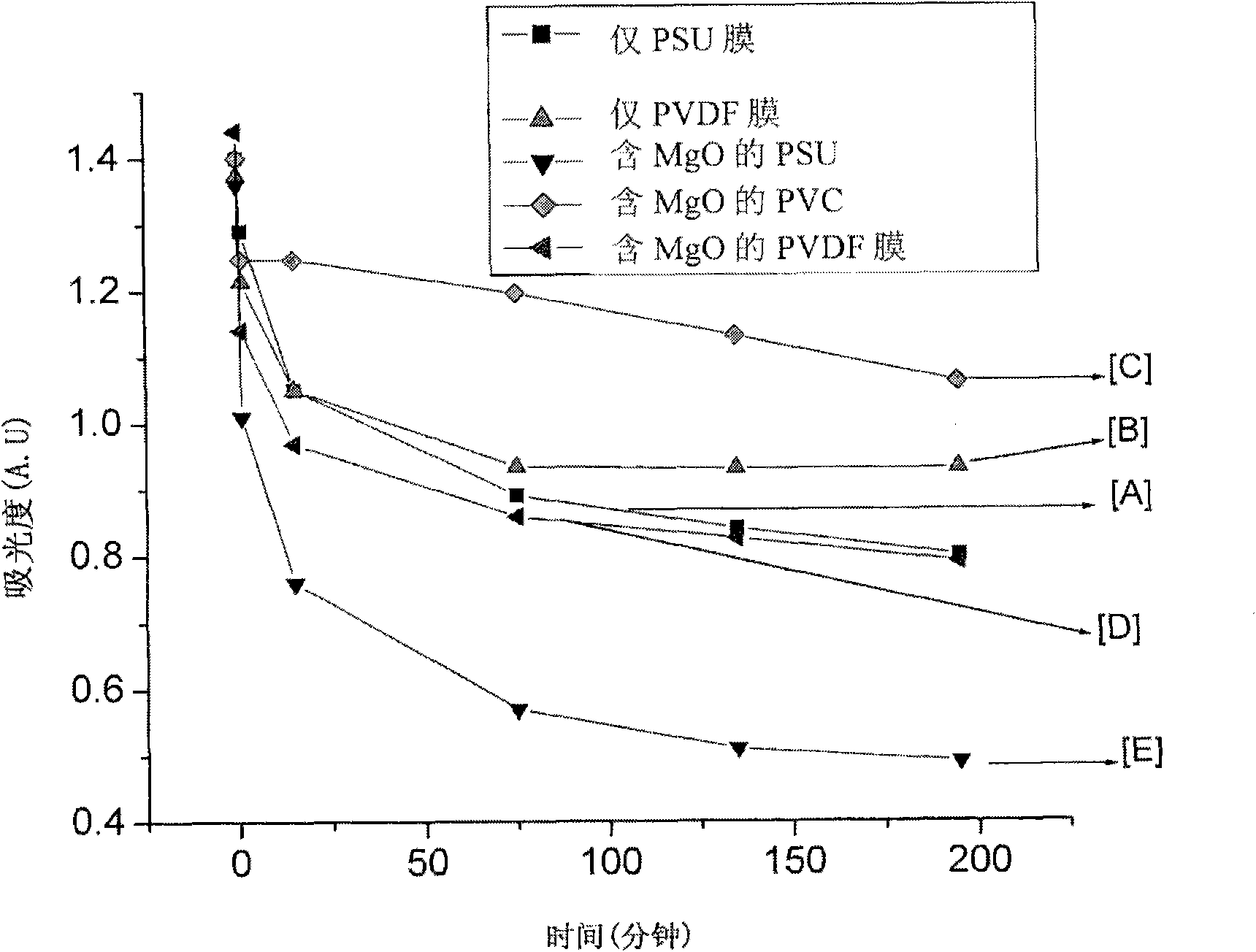

[0076] Example 3 - Detoxification of paraoxon using nanocomposite fibers

[0077] Following the successful fabrication of nanocomposite membranes as described above, a detoxification test against the neurostimulant paraoxon was carried out for proof of concept and for selection of suitable membranes. UV studies were performed on individual polymer films and films containing MgO nanoparticles (see figure 2 ): (a) paraoxon on polysulfone only; (b) paraoxon on PVDF copolymer only; (c) paraoxon on polysulfone containing MgO (d) paraoxon on PVC containing MgO and (e) paraoxon on MgO-containing PVDF copolymer.

[0078] Polysulfone was found to have better adsorption properties compared to PVDF (e) and PVC (d). These results suggest that the selection of an appropriate polymer support is also important in order to preserve MgO activity.

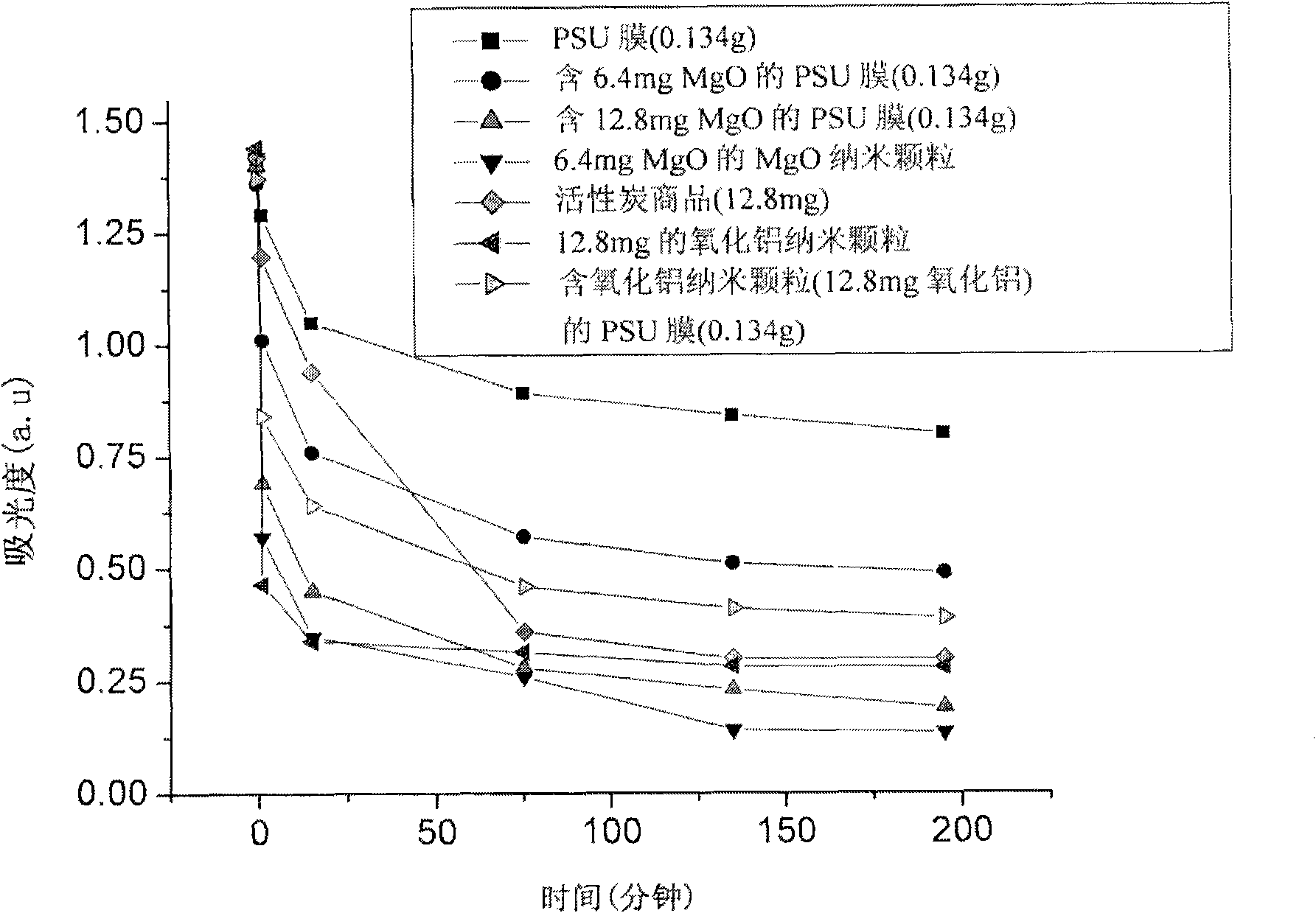

[0079] Also carried out in only polysulfone polymers, nanocomposite membranes and MgO nanoparticles, Al 2 o 3 UV adsorption study of paraoxon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com