Copper and iron-loaded modified activated carbon absorbent and method for preparing same

An activated carbon adsorption and activated carbon technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve problems such as complex processes, secondary pollution, and high energy consumption, achieve mild reaction conditions, improve purification efficiency, and reduce purification cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

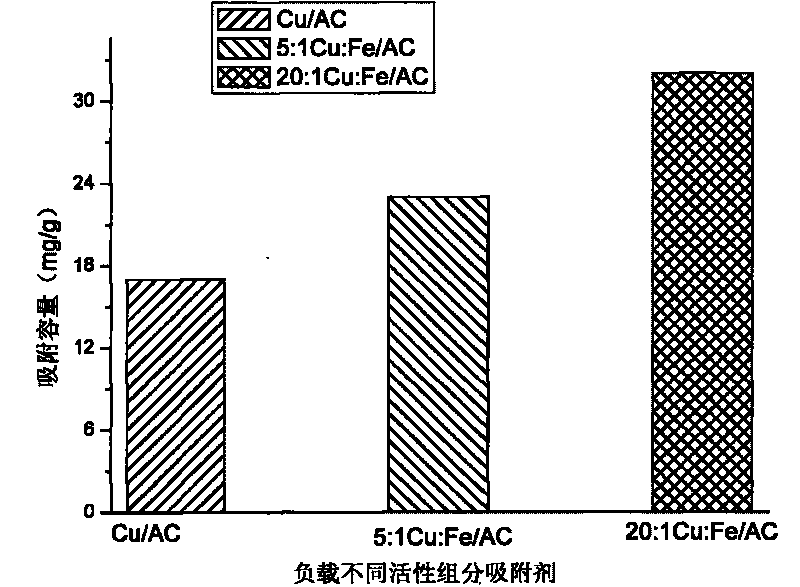

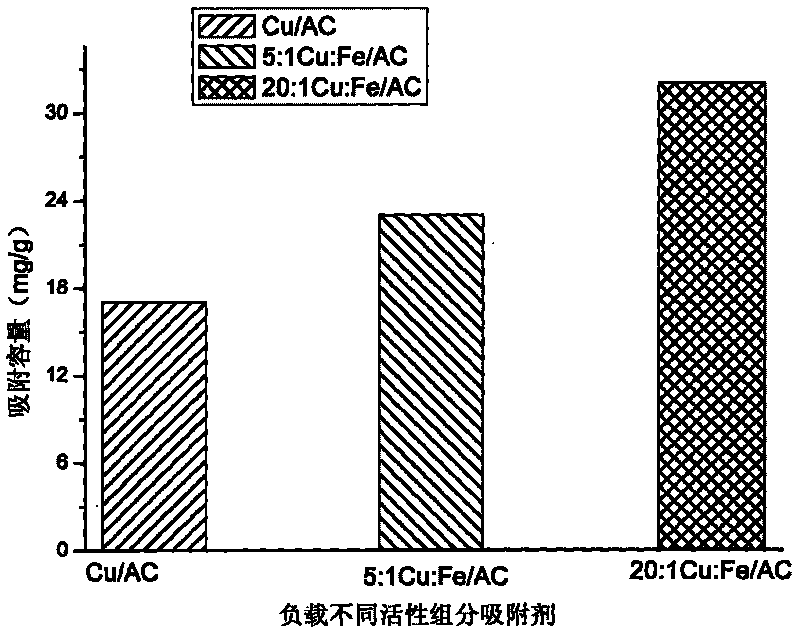

Embodiment 1

[0023] Wash conventional commercially available coal-based activated carbon with distilled water, then conventionally ultrasonically clean it for 40 minutes, place it in an oven to dry, and dry it at 100°C for 18 hours to take it out for use; weigh 1.2202g Cu(NO 3 ) 2 ·3H 2 O and 0.4102g Fe(NO 3 ) 3 9H 2 Mix O to make Cu / Fe=5:1 (molar ratio), dissolve it with 24ml distilled water to obtain the impregnation solution; weigh 25g of the above-mentioned dried activated carbon and immerse it in the impregnation solution, fully stir, and use conventional Ultrasonic impregnation for 60 minutes, then placed in an oven, dried at 100°C for 12 hours; finally placed in a muffle furnace, baked at 350°C for 6 hours, taken out, placed in a drying dish and cooled to room temperature, you can get The activated carbon adsorbent that adsorbs low-concentration phosphine gas, the purification effect is shown in Table 1.

[0024] Table 1 purification effect:

[0025] time / minute

Embodiment 2

[0027] The coal-based activated carbon was washed with distilled water, cleaned by conventional ultrasonic cleaning, placed in an oven to dry, dried at 80°C for 24 hours, and taken out for use; weighed 1.2202g Cu(NO 3 ) 2 ·3H 2 O and 0.2051gFe(NO 3 ) 3 9H 2 O mixed to make Cu / Fe=10:1 (molar ratio), dissolved in 24ml of distilled water to obtain the impregnating solution; weigh 25g of the above-mentioned dried activated carbon and immerse in the impregnating solution, fully stir, and use conventional Ultrasonic impregnation for 50 minutes, dried in an oven at 80°C for 24 hours; finally placed in a muffle furnace and baked at 200°C for 8 hours, taken out and placed in a drying dish to cool to room temperature to obtain low-concentration phosphating The activated carbon adsorbent for hydrogen gas, the purification effect is shown in Table 2.

[0028] Table 2 purification effect:

[0029] time / min

Embodiment 3

[0031] The coal-based activated carbon was washed with distilled water, then cleaned by conventional ultrasonic waves, then dried in an oven, dried at 120°C for 12 hours, and taken out for use; weighed 1.2202g Cu(NO 3 ) 2 ·3H 2 O and 0.1025gFe(NO 3 ) 3 9H 2O mixed to make Cu / Fe=20:1 (molar ratio), dissolved in 24ml of distilled water to obtain the impregnating solution; weigh 25g of the above-mentioned dried activated carbon and immerse in the impregnating solution, fully stir, and use conventional Ultrasonic impregnation for 40 minutes, dried in an oven at 90°C for 18 hours; finally placed in a muffle furnace and roasted at 600°C for 2 hours, taken out and placed in a drying dish to cool to room temperature to obtain low-concentration phosphating The activated carbon adsorbent for hydrogen gas, the purification effect is shown in Table 3.

[0032] Table 3 purification effect:

[0033] time / min

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com