Anti-drag and abrasion-resistant paint for natural gas line

A technology of natural gas pipelines and wear-resistant coatings, which is applied in the direction of epoxy resin coatings and coatings, which can solve the problems of wear resistance, poor solvent immersion resistance, and insufficient low friction coefficient of the coating surface, etc., and achieve good drag reduction effect, easy construction in winter, and high cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Raw material ratio:

[0048] Raw material composition is by mass percentage:

[0049] Ingredient A:

[0050] Phenalkamine curing agent: 27%;

[0051] Leveling agent: 0.15%;

[0052] Defoamer: 0.17%;

[0053] Dispersant: 0.55%;

[0054] Thickener: 4.0%;

[0055] White ceramic powder: 5.5%;

[0056] Iron oxide red powder: 15%;

[0057] Mica iron oxide: 12%;

[0058] Iron oxide yellow powder: 3.5%;

[0059] Light calcium carbonate: 4.0%;

[0060] Environmentally friendly mixed solvent: 28.13%.

[0061] Ingredient B:

[0062] Epoxy resin: 57%;

[0063] Leveling agent: 1.6%;

[0064] Environmentally friendly mixed solvent: 41.4%.

[0065] When the paint is used, component A and component B are used in combination according to the mass ratio A:B=1.35:1.

[0066] Described epoxy resin is provided by Baling Petrochemical Epoxy Resin Factory or Shenzhen Jiadida Chemical Co., Ltd.;

[0067] Described phenalkamine curing agent is provided by Shanghai Hongke Che...

Embodiment 2

[0087] (1) Raw material ratio:

[0088] Raw material composition is by mass percentage:

[0089] Ingredient A:

[0090] Phenalkamine curing agent: 31%;

[0091] Leveling agent: 0.22%;

[0092] Defoamer: 0.20%;

[0093] Dispersant: 0.7%;

[0094] Thickener: 3.3%;

[0095] White ceramic powder: 4.0%;

[0096] Iron oxide red powder: 15%;

[0097] Mica iron oxide: 8%;

[0098] Iron oxide yellow powder: 4.5%;

[0099] Light calcium carbonate: 6.0%;

[0100] Environmentally friendly mixed solvent: 27.08%.

[0101] Ingredient B:

[0102] Epoxy resin: 60%;

[0103] Leveling agent: 1.8%;

[0104] Environmentally friendly mixed solvent: 38.2%.

[0105] When the paint is used, component A and component B are used in combination according to the mass ratio A:B=1.35:1.

[0106] (2) Preparation method

[0107] The preparation method is the same as in Example 1.

Embodiment 3

[0109] (1) Raw material ratio:

[0110] Raw material composition is by mass percentage:

[0111] Ingredient A:

[0112] Phenalkamine curing agent: 34%;

[0113] Leveling agent: 0.25%;

[0114] Defoamer: 0.22%;

[0115] Dispersant: 0.9%;

[0116] Thickener: 3.0%;

[0117] White ceramic powder: 5.0%;

[0118] Iron oxide red powder: 16%;

[0119] Mica iron oxide: 6%;

[0120] Iron oxide yellow powder: 4%;

[0121] Light calcium carbonate: 5.0%;

[0122] Environmentally friendly mixed solvent: 25.63%.

[0123] Ingredient B:

[0124] Epoxy resin: 63%;

[0125] Leveling agent: 2.0%;

[0126] Environmentally friendly mixed solvent: 35%.

[0127] When the paint is used, component A and component B are used in combination according to the mass ratio A:B=1.35:1.

[0128] (2) Preparation method

[0129] The preparation method is the same as in Example 1.

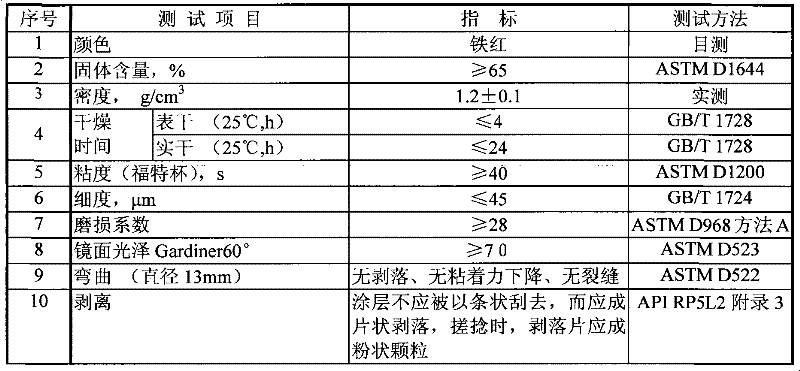

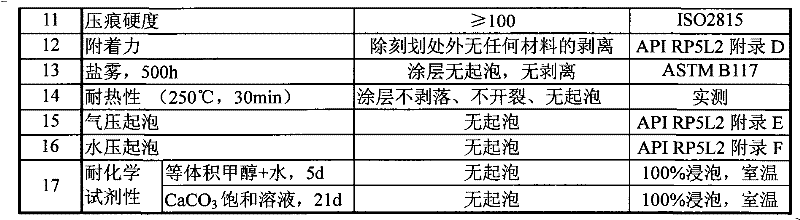

[0130] The characteristics of a drag-reducing and wear-resistant coating for natural gas pipelines of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com