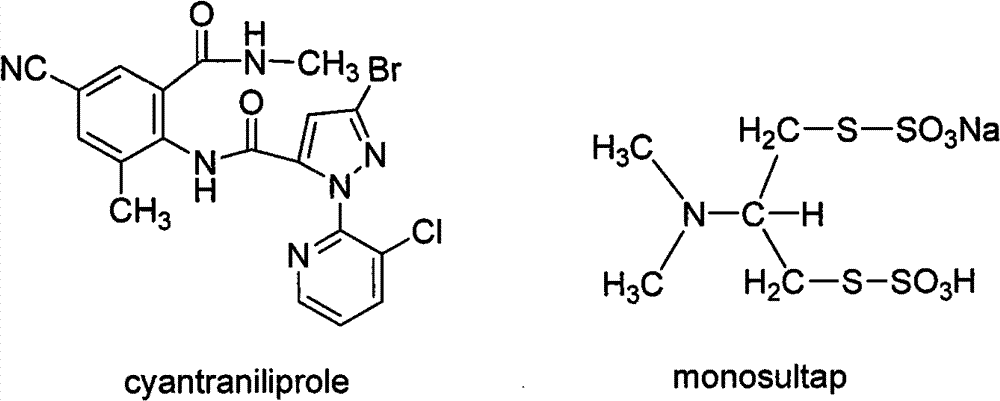

Insecticidal composition containing cyanogen insect amide and molosultap and application thereof

A technology of insecticidal composition and cyantraniliprole, which is applied in the direction of insecticide, application, biocide, etc., can solve the problems of the insecticidal composition of cyantraniliprole and monosultap that have not yet been seen, and achieve excellent effect and reduce Production and use costs, and the effect of extending the safe service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

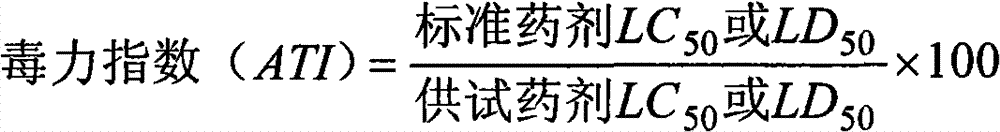

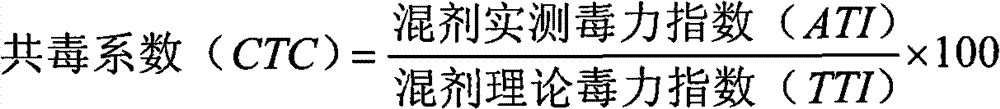

Method used

Image

Examples

Embodiment 1

[0015] Example 1: First weigh 10 g of cyantraniliprole, 1 g of insecticide, 10 g of lignosulfonate, 9 g of polyoxyethylene polyoxypropylene block copolymer, 2 g of alkylphenol polyoxyethylene ether, and polyoxyethylene sorbitan 2 g of alcohol anhydride ester, 2 g of propylene glycol, 2 g of polyvinyl alcohol, 3 g of methanol, 2 g of dimethylformamide, 1 g of epoxidized soybean oil, 5 g of xylene, and 51 g of deionized water. Then, the oil phase is added to the water phase under normal temperature and high-speed shear stirring, and the mixture is uniformly stirred to make the average liquid diameter less than 2 μm, to obtain an 11% water emulsion product.

Embodiment 2

[0016] Example 2: First weigh 2 g of cyantraniliprole, 0.2 g of insecticide, 10 g of phenylphenol polyoxyethylene ether phosphate, 10 g of polyoxyethylene fatty acid ester, 5 g of polyoxyethylene polyoxypropylene block copolymer, and alkane 5 g of benzene sulfonate, 3 g of silicone oil, 5 g of gum arabic, 2 g of sorbitol, 2 g of acetone, 3 g of dimethyl sulfoxide, 1 g of pyrrolidone, and 51.8 g of deionized water. Then, the oil phase is added to the water phase under normal temperature and high-speed shear stirring, and the mixture is stirred and mixed uniformly to make the average liquid diameter less than 2 μm to obtain a 2.2% water emulsion product.

Embodiment 3

[0017] Example 3: First weigh 1 g of cyantraniliprole, 10 g of insecticide, 10 g of phenethyl phenol polyoxyethylene ether phosphate, 10 g of polyoxyethylene polyoxypropylene block copolymer, and phenethyl phenol polyoxyethylene polyoxyethylene 5 g of propylene ether, 2 g of polyvinyl alcohol, 1 g of ethylene glycol, 3 g of ethyl acetate, 2 g of methanol, 1 g of epoxidized soybean oil, and 55 g of deionized water. Then, the oil phase is added to the water phase under normal temperature and high-speed shear stirring, and the mixture is uniformly stirred to make the average liquid diameter less than 2 μm, to obtain an 11% water emulsion product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com