ThMn12 type soft magnetic material and preparation method thereof

A soft magnetic composite material and magnetic field technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of narrow frequency band, high-frequency soft magnetic performance reduction, high complex permeability, etc., and achieve the effect of eliminating electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

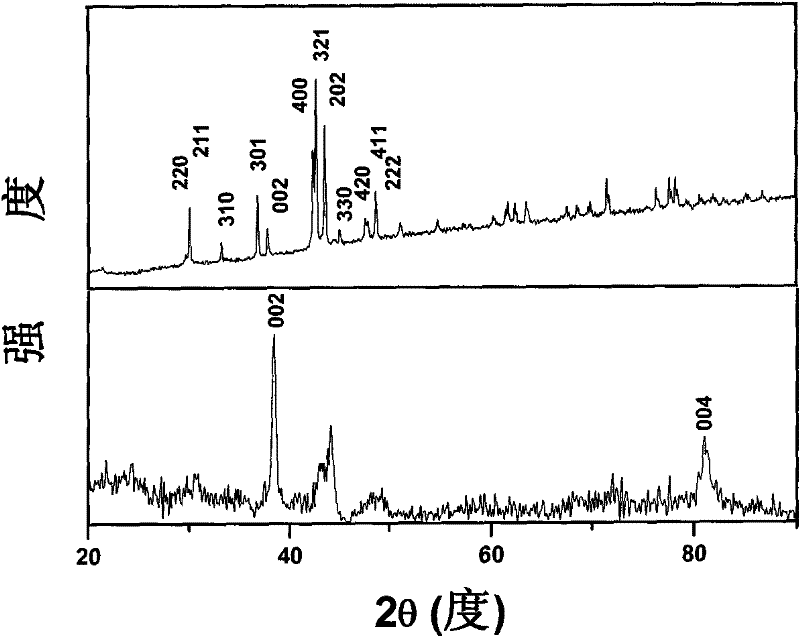

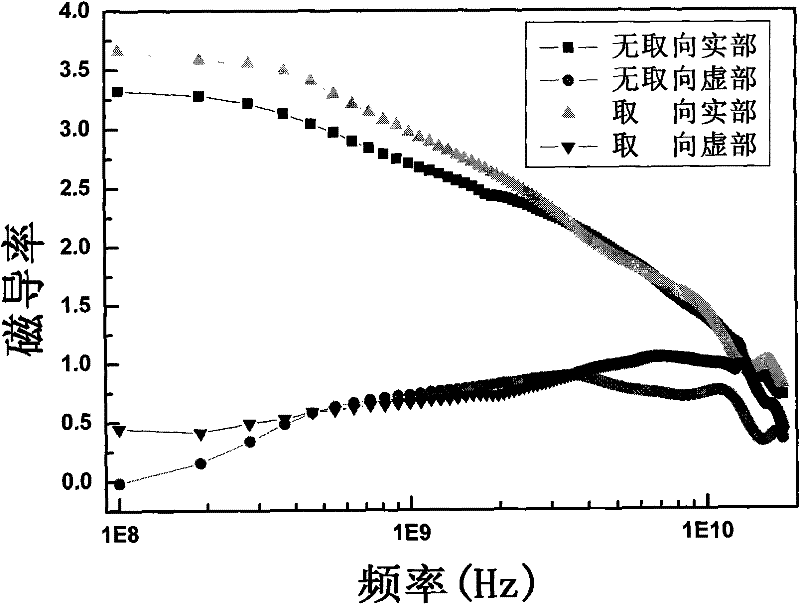

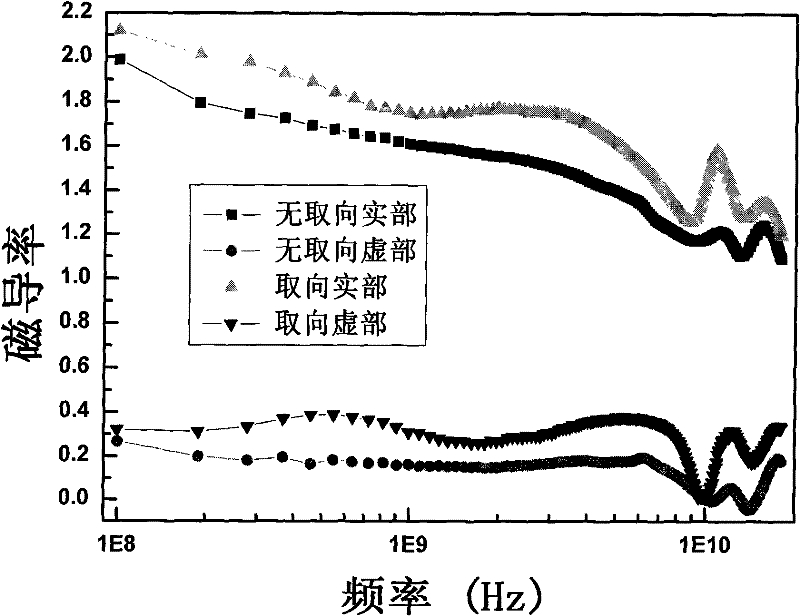

[0023] Weigh 1.50g of neodymium and 3.91g of iron, as well as 1.02g of vanadium and 1.77g of cobalt, melt them into ingots in an electric arc furnace under the protection of argon, and then put them into a vacuum quartz tube for homogenization at 950°C for one week. Grind the homogenized ingot into particles of about 50 microns with an agate mortar, then put the particles into an agate ball mill jar and add 100ml of n-hexane and 0.2ml of phthalate coupling agent to grind on a planetary ball mill to make 10 For powder particles below micron, in ball milling, the mass ratio of ball to material is 20:1, the speed of ball mill is 400r / min, and the ball milling time is set to 12h. Finally, the samples were taken out and dried, and the results were as follows: Figure 1 shown. Depend on figure 1 It can be seen that before orientation, the characteristic peaks of the sample are obvious, so it can be known that the sample has a ThMn12 structure, and there is no other impurity phase ...

Embodiment 2

[0026] Weigh 1.49g of praseodymium, 5.58g of iron, and 1.92g of molybdenum, melt them into ingots in an electric arc furnace under the protection of argon, and then put them into a vacuum quartz tube for homogenization at 950°C for one week. Grind the homogenized ingot into particles of about 50 microns with an agate mortar, then put the particles into an agate ball mill jar and add 100ml of n-hexane and 0.2ml of phthalate coupling agent to grind on a planetary ball mill to make 10 For powder particles below micron, in ball milling, the mass ratio of ball to material is 20:1, the speed of ball mill is 400r / min, and the ball milling time is set to 12h. Finally, the samples were taken out and dried.

[0027]Add titanate coupling agent diluted with isopropanol to the powder after ball milling, wherein the mass of titanate is 1% of the mass of the sample, stir and ultrasonically for 30 minutes, and dry. After ultrasonication, the sample and the paraffin wax dissolved in n-hexane ...

Embodiment 3

[0029] Weigh 0.98g of neodymium, 5.89g of cobalt (purity 0.9999) and 1.02g of vanadium, melt them into ingots in an electric arc furnace under the protection of argon, and then put them into a vacuum quartz tube for heat preservation and homogenization at 950°C for one week. Grind the homogenized ingot into particles of about 50 microns with an agate mortar, then put the particles into an agate ball mill jar and add 100ml of n-hexane and 0.2ml of phthalate coupling agent to grind on a planetary ball mill to make 10 For powder particles below micron, in ball milling, the mass ratio of ball to material is 20:1, the speed of ball mill is 400r / min, and the ball milling time is set to 12h. Finally, the samples were taken out and dried, and the results were as follows: Figure 1 shown.

[0030] Add titanate coupling agent diluted with isopropanol to the powder after ball milling, wherein the mass of titanate is 1% of the mass of the sample, stir and ultrasonically for 30 minutes, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com