Polymer containing pyridine ring and composition magnetic membrane material and preparation method thereof

A technology of magnetic film and pyridine ring, applied in the application of magnetic film to substrate, magnetic layer, organic chemistry, etc., to achieve the effect of low hysteresis loss, easy processing and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

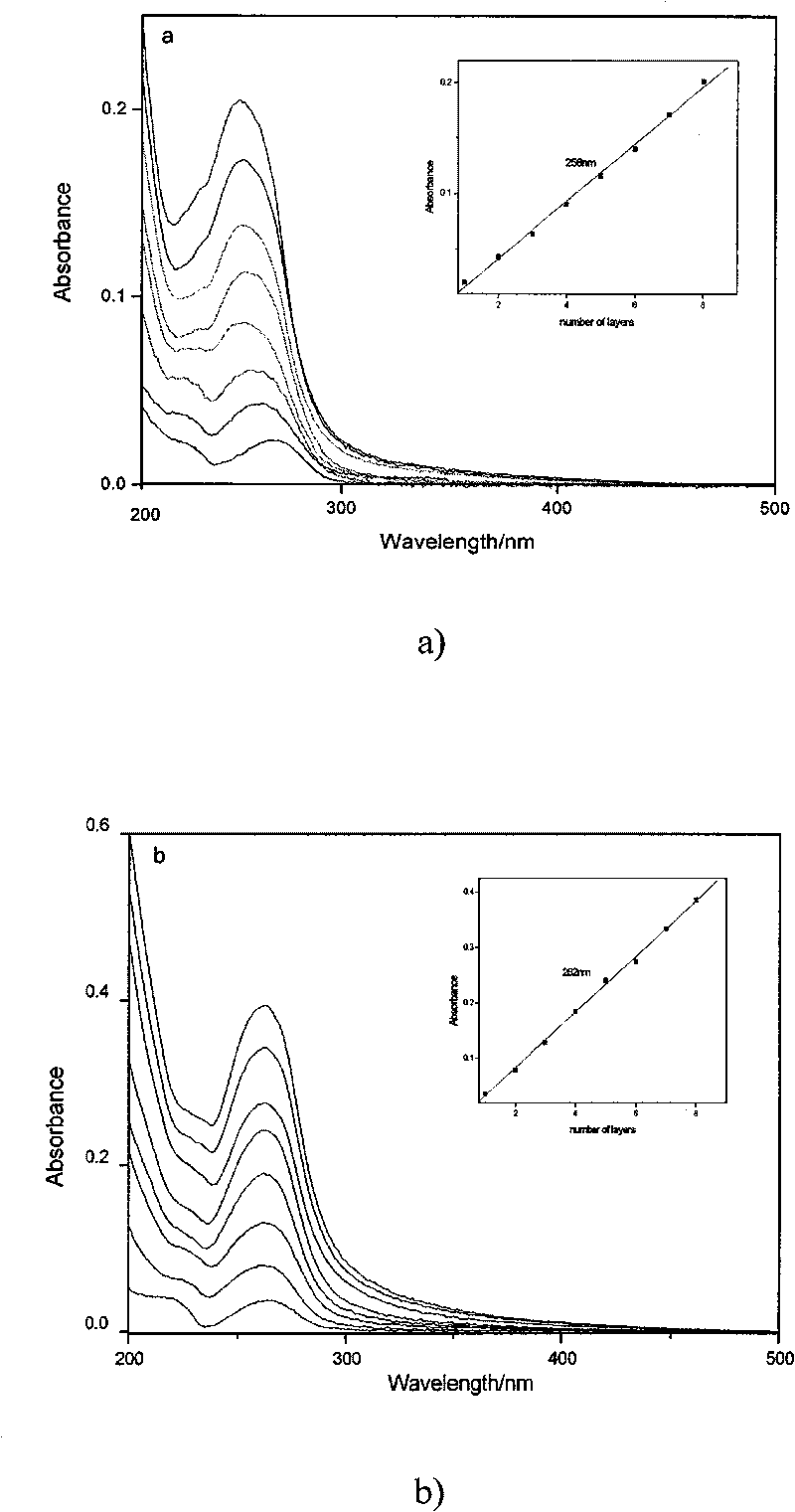

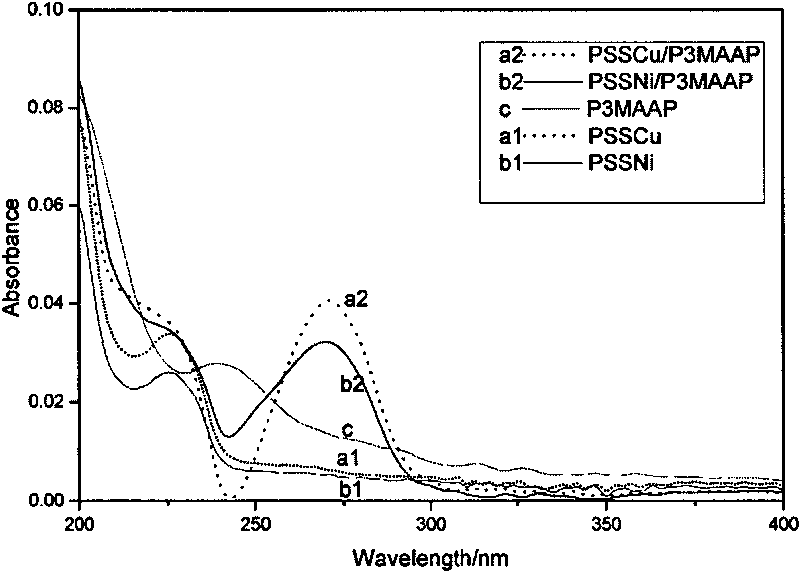

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation method of 4-methacrylamidopyridine monomer (4-MAAP)

[0033] At 0°C, dissolve 2.12g (0.0212mol) of methacryloyl chloride (MAC) in 10ml of anhydrous tetrahydrofuran (THF), and slowly add the above solution dropwise to the solution containing 4-aminopyridine (2g, 0.0212mol) and triethylamine (3ml, 0.0212mol) in 60ml of anhydrous THF solution. After the dropwise addition, put it in an ice bath to react for 24 hours, filter it with suction, and wash it thoroughly with THF. At room temperature, the resulting filtrate and washings were concentrated in vacuo to obtain a light yellow solid, which was then washed with 5% Na 2 CO 3 Wash with aqueous solution and deionized water, and dry in a vacuum oven at room temperature for 24 hours. The dried solid was dissolved in 8 ml of THF, poured into 400 ml of n-hexane, and left to stand overnight to obtain white needle-like crystals which were 4-methacrylamidopyridine monomer (4-MAAP). Yield: 80%, mp 1...

Embodiment 2

[0034] Embodiment 2: the preparation method of 3-methacrylamidopyridine monomer (3-MAAP)

[0035]Place a single-necked flask containing 3-aminopyridine (2g, 0.0212mol), triethylamine (6ml, 0.0424mol), hydroquinone (0.1g) and 40ml of anhydrous THF in an ice-salt bath below 0°C, While stirring, 10 ml of anhydrous THF dissolved with methacryloyl chloride (2.12 g, 0.0212 mol) was slowly added to the flask. After the dropwise addition, continue to react in the ice-salt bath for 8h. The reaction solution was taken out and filtered with suction, and washed thoroughly with THF. The resulting lower layer was concentrated in vacuo at room temperature to give an oil. Use acetone as the eluent to pass through the column, and then recrystallize through ether to obtain milky white needle crystals which are 3-methacrylamidopyridine monomer (3-MAAP). Yield: 85%, mp 85-86°C. FT-IR (KBr, cm -1 ):v 3438(w), 3226-2851(m), 1668(s), 1629(s), 1600(s), 1548(s), 1485(s), 1414(s), 1373(s), 1336(s...

Embodiment 3

[0036] Embodiment 3: the preparation that contains the polymkeric substance (P4MAAP) of p-pyridine ring

[0037] Add 0.5g of 4-methacrylamidopyridine monomer (4-MAAP), 0.005g of azobisisobutyronitrile (AIBN) and 3ml of anhydrous THF into a dry polymerization bottle, freeze, melt and degas three times. React in an oil bath at 65°C for 24h. The reaction solution was precipitated in ether, filtered, and the resulting white solid P4MAAP was washed repeatedly with ether and THF, and dried in vacuum at 60°C for 48h. Yield: 75%, intrinsic viscosity: [η] = 14.0ml / g (DMF, 30°C). FT-IR (KBr, cm -1 ): v 3390-2980(m), 1686(m), 1590(s), 1509(s), 1415(m), 1328(m), 1285(m), 1211(m), 1150(m), 1001(m), 825(m). 1 H NMR (DMSO-d 6 ): δ (ppm) 0.90-1.07 (m, 3H, CH 3 ), 1.73-2.06 (m, 2H, CH 2 ), 7.52 (s, 2H, 2, 6-PyH), 8.31 (s, 2H, 3, 5-PyH), 9.42 (s, 1H, NH).

[0038] The structural formula is

[0039]

[0040] In the formula, Py is para-pyridine, and n is a chain link of a polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Magnetic saturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com