Method for synthesizing betulic acid by carrying out biocatalysis on betulin

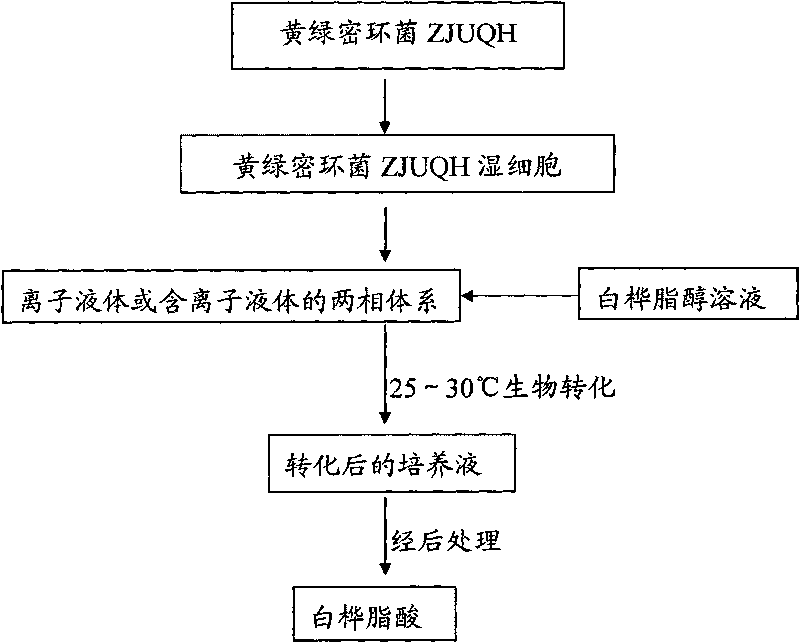

A technology of betulin alcohol and betulinic acid, which is applied in the fields of bioengineering and microbial fermentation, can solve the problems of affecting the catalytic effect of enzymes on substrates, microbial cell toxicity, long conversion reaction time, etc., so as to shorten the catalytic reaction time and conversion time. Short, easy to recycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0035] Examples 1-8 Synthesis of betulinic acid from betulin catalyzed by the fungus ZJUQH in different two-phase systems

[0036] (1) Insert Armillaria chrysanthemum ZJUQH into sterilized potato dextrose agar medium (its raw material mass percentage is composed of: potato 20%, glucose 2% and agar 3%), at 28 ℃, after 4 days of activation, prepare Become Armillaria chrysanthemum ZJUQH spore suspension, then insert potato glucose liquid culture medium (its raw material mass percentage is made up of: potato 20%, glucose 2%, surplus is water, pH is natural), at 28 ℃, rotating speed is 120r / min rotary shaker for 3 days to obtain seed culture solution. The concentration of spores in Armillaria chrysanthemum ZJUQH spore suspension was 1×10 6 individual / ml, the volume ratio of the potato dextrose liquid medium to the Armillaria chrysanthemum ZJUQH spore suspension was 30.

[0037] The seed culture solution was refrigerated and centrifuged at 3000 r / min for 30 minutes, washed with st...

Embodiment 9~14

[0046] Examples 9-14 Synthesis of betulinic acid catalyzed by Clostridium chrysogenum ZJUQH in a two-phase system with different ionic liquid concentrations

[0047] (1) The preparation of Armillaria chrysanthemum ZJUQH wet cells is the same as in Example 1.

[0048] (2) Add 5 mL of ionic liquid or a mixed solvent of ionic liquid and n-hexane into a stoppered test tube to form a two-phase system. The volume concentration of the ionic liquid in the two-phase system is 3% to 100%. ZJUQH wet cells, the amount of ZJUQH wet cells of Clostridium chrysogenum chrysogenum ZJUQH is 200 g per liter of the two-phase system, pre-cultured on a rotary shaker at 28° C. with a rotation speed of 200 r / min for 10 minutes to obtain a pre-culture system.

[0049] (3) Add 0.05 mL of dimethyl sulfoxide solution with a concentration of 7.5 mg / mL betulin to the above pre-culture system, and continue to ferment and culture on a rotary shaker at 28° C. with a rotation speed of 200 rpm for 18 hours to ob...

Embodiment 15~21

[0054] Examples 15-21 Synthesis of betulinic acid catalyzed by Cyclobacter chrysogenum ZJUQH in different co-substrates

[0055] (1) The preparation of Armillaria chrysanthemum ZJUQH wet cells is the same as in Example 1.

[0056] (2) Add 5mL of ionic liquid [EMIM]BF to a stoppered test tube 4 A mixed solvent with n-hexane forms a two-phase system, the volume concentration of the ionic liquid in the two-phase system is 50%, and a co-substrate is added to the two-phase system at the same time, and the amount of the co-substrate added per liter of the two-phase system is 0.1mol. Add the above-mentioned C. chrysogenum ZJUQH wet cells under aseptic conditions. The amount of C. chrysogenum ZJUQH wet cells is 200 g per liter of the two-phase system. Pre-cultivate on a rotary shaker at 28 ° C for 10 min at a speed of 200 r / min to obtain pre-cultured system.

[0057] (3) Add 0.05 mL of dimethyl sulfoxide solution with a concentration of 7.5 mg / mL betulin to the above pre-culture sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com