Phosphorus-containing phenolic aldehyde and preparation method thereof

A technology of phenolic and organic phosphorus, which is applied in the field of polymer compounds, can solve the problems of copper clad laminate damage, high phosphorus content, and many free phenols, and achieve good flame retardancy and heat resistance, simple preparation method, low phosphorus content, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

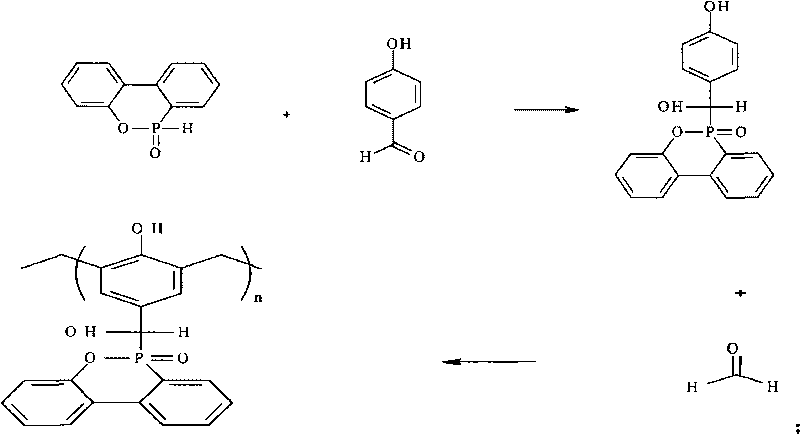

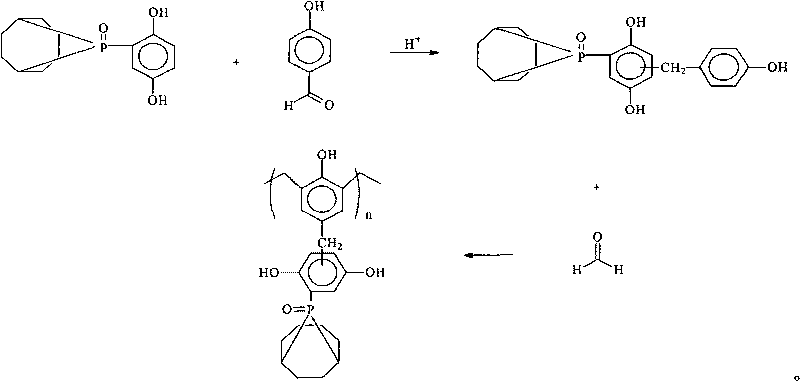

Method used

Image

Examples

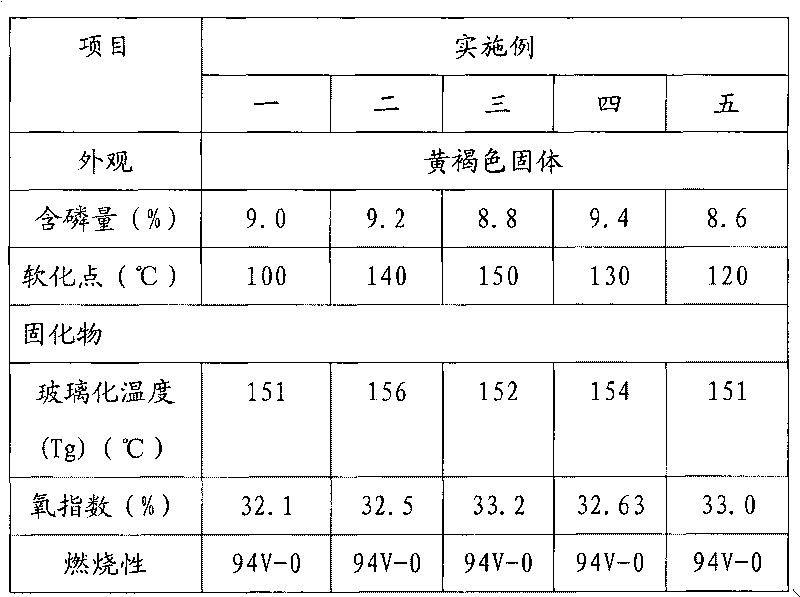

Embodiment 1

[0020] The steps of the present embodiment are as follows: the raw material is pressed by the following weight

[0021] 9,10-dihydro-9-oxa-10phosphaphenanthrene-10 oxide 200g,

[0022] p-Hydroxybenzaldehyde 120g,

[0023] Benzenesulfonic acid 4g,

[0024] Add it into a four-necked flask equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen inlet to stir and feed nitrogen; at the same time, the temperature is raised to 80°C, and refluxed for 8 hours to obtain a phosphorus content of 9.0% and a softening point of 100°C. Phosphorous phenolic.

[0025] The raw materials used in this example are all commercially available, and will not be repeated here.

Embodiment 2

[0027] The steps of the present embodiment are as follows: the raw material is pressed by the following weight

[0028] 2-(6H-dibenzo-5-oxa-6-phosphono-6-phenyl-1,4-hydroquinone 350g,

[0029] o-Hydroxybenzaldehyde 200g,

[0030] Benzoic acid 7g,

[0031] Add it into a four-necked flask equipped with a stirrer, a thermometer, a reflux condenser and a nitrogen inlet to stir and feed nitrogen; at the same time, it is heated to 120°C and refluxed for 6 hours to obtain a phosphorus content of 9.2% and a softening point of 140°C. Phosphorous phenolic.

[0032] The raw materials used in this example are all commercially available, and will not be repeated here.

Embodiment 3

[0034] The steps of the present embodiment are as follows: the raw material is pressed by the following weight

[0035] 4-Cyclooctene containing phosphorus hydroquinone 400g,

[0036] m-Hydroxybenzaldehyde 200g,

[0037] Salicylic acid 10g,

[0038] Add it into a four-necked flask equipped with a stirrer, a thermometer, a reflux condenser and a nitrogen inlet to stir and feed nitrogen; at the same time, it is heated to 150°C and refluxed for 4 hours to obtain 8.8% phosphorus content and a softening point of 150°C. Phosphorous phenolic.

[0039] The benzaldehyde and catalyzer used in the present embodiment are all available on the market, and the phosphorus-containing hydroquinone used in the present embodiment is all obtained by self-made by conventional techniques (the preparation method of epoxy resin is referring to the publication of Mechanical Industry Publishing House. Titled "Epoxy Resin Application Principles and Technologies", Section 2.4 of the second chapter, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com