Metal surface anti-corrosion layer structure and coating method thereof

A technology of metal surface and anti-corrosion layer, which is applied in the field of anti-corrosion layer structure and coating on the surface of electrical equipment with aluminum alloy substrates on the sea. Excellent protection performance, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

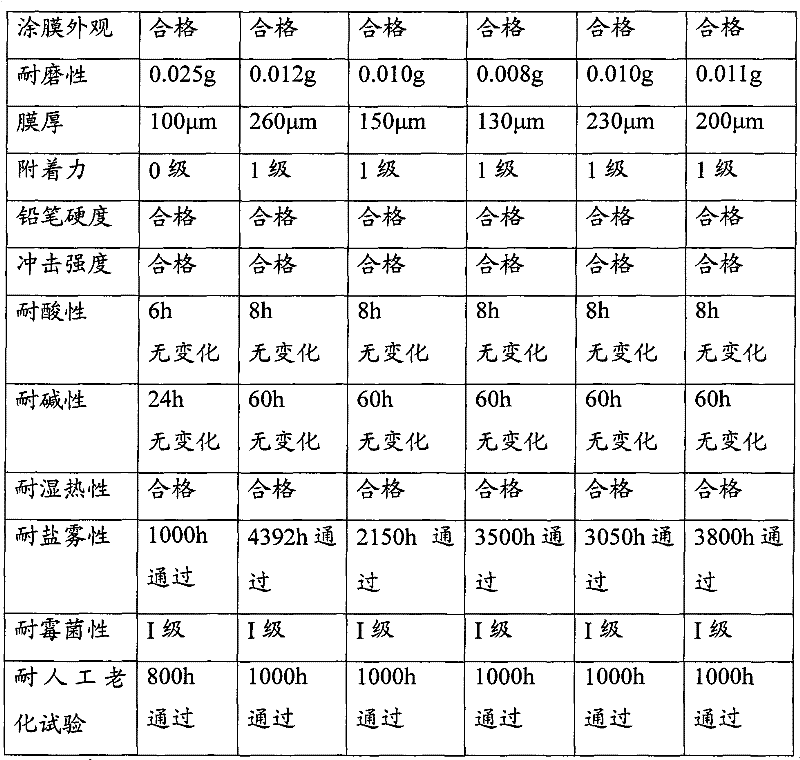

Embodiment 1

[0035] Choose an explosion-proof lamp for offshore oil platforms (the shell of the lamp is aluminum alloy) to coat its outer surface. The process steps are:

[0036] 1. Prepare the primer coating: the primer is composed of a curing agent prepared from epoxy resin and polyamide with a weight ratio of 3:1, pour it into the spray barrel, and keep stirring during use.

[0037] 2. Clean with acid, clean water, and deionized water in sequence to thoroughly remove grease and other impurities on the surface of the substrate; then, sand the surface of the metal substrate to derust to Sa 2.5-3.0. After sandblasting, at least reach Sa2.5, showing a sharp and rough surface.

[0038]3. Spray the primer for the entire structure or parts, and at the same time, focus on all dead corners of the entire lamp structure or its parts. When painting by hand, the spray hole diameter is required to be 0.5mm, and the fan angle is 40 degrees. Spraying surface requirements: the paint nozzle adopts a sp...

Embodiment 2

[0047] It is basically the same as in Example 1, except that it is used for the surface of die-casting zinc alloy substrate electrical connectors, the primer layer coating, the intermediate paint layer coating and the top coat coating are all composed of curing agent and thinner, wherein the primer layer coating The medium curing agent is formulated from epoxy resin and polyamide with a weight ratio of 3:1. The curing agent in the paint coating is prepared from acrylic acid and polyurethane in a weight ratio of 7:1, and the diluent is all butyl alcohol. The content of the diluent in each layer of the prepared coating is 5% by weight, and the thickness of the primer layer is 50 μm. The layer thickness was 50 μm, the topcoat layer thickness was 50 μm. Of course, the diluent can also use other commonly used diluents in the art, and the ratio of the diluent is not greater than 20% of the total weight of the paint prepared for each layer.

Embodiment 3

[0049] It is basically the same as Example 2, except that it is used on the surface of the stuffing box of navy brass marine substrate, the curing agent in the primer layer coating is prepared from epoxy resin and polyamide with a weight ratio of 3:1, and the intermediate paint layer The curing agent in the paint is prepared from high-build epoxy resin and polyamide with a weight ratio of 3:1. The curing agent in the topcoat paint is prepared from acrylic acid and polyurethane with a weight ratio of 6:1. The diluent is all made of acrylic acid. The mixture of alcohol and toluene, the diluent content is 8% by weight in the coating of each layer preparation, and the thickness of primer layer is 40 μm, and the thickness of middle paint layer is 50 μm, and the thickness of topcoat layer is 40 μm. Of course, the diluent can also use other commonly used diluents in the art, and the ratio of the diluent is not greater than 20% of the total weight of the paint prepared for each layer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com