Micron/nanoscale BiOCl film material and preparation method thereof

A thin-film material, nano-scale technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of difficult to homogenize product size and morphology, unfavorable for mass production, and poor product dispersion. , to achieve the effect of uniform morphology, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

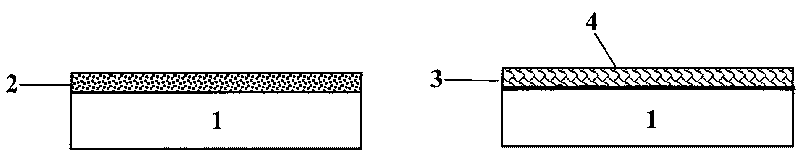

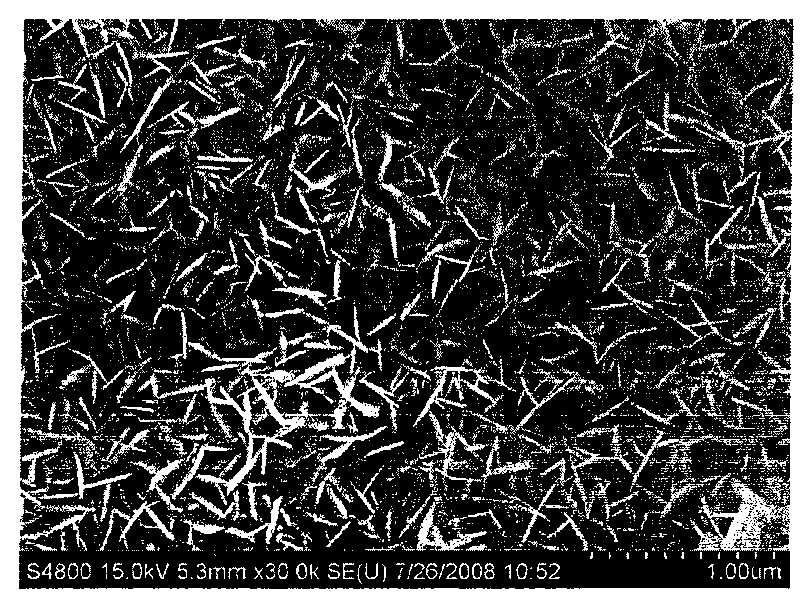

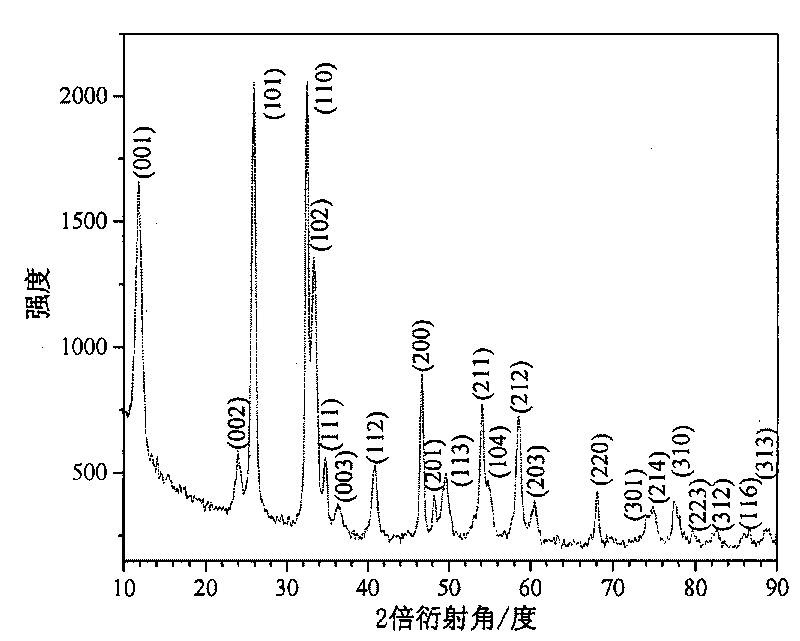

[0035] The micron / nano-scale BiOCl thin film material prepared in this embodiment uses a silicon wafer as the substrate 1, and a layer of metallic bismuth film 2 is deposited on the substrate 1. The metallic bismuth film 2 is used as a raw material to form a layer consisting of two-dimensional The BiOCl thin film 3 composed of BiOCl nanosheets 4; wherein the metal bismuth thin film 2 has a thickness of 200 nm, and the BiOCl thin film has a thickness of 200 nm.

[0036] First use the silicon wafer as the substrate 1, using acetone, alcohol, and deionized water as the cleaning agent, and ultrasonically clean each for 10 minutes. After cleaning, take it out and dry it with nitrogen, then dry it in a vacuum oven at 120°C for 1 hour, and take it out after cooling. . A layer of metallic bismuth thin film 2 is deposited on the silicon wafer treated as above by magnetron sputtering, and the deposition condition: background pressure 1×10 -5 Pa, a sputtering power of 50W, an Ar flow rate o...

Embodiment 2

[0038] The micron / nano-scale BiOCl film material prepared in this embodiment uses a cover glass as the substrate 1, and a layer of metallic bismuth film 2 is deposited on the substrate 1, and the metallic bismuth film 2 is used as a raw material to form a layer consisting of two The BiOCl thin film 3 composed of BiOCl nanosheets 4; wherein the metal bismuth thin film 2 has a thickness of 200 nm, and the BiOCl thin film has a thickness of 200 nm.

[0039] First, the cover glass was used as the substrate 1, and acetone, alcohol, and deionized water were used as the cleaning agent, each ultrasonically cleaned for 10 minutes, and then taken out and dried with nitrogen, then dried in a vacuum oven at 120°C for 1 hour, and then taken out after cooling. Magnetron sputtering is used to deposit metal bismuth film 2 on the cover glass treated as above, and the deposition condition: background pressure 1×10 -5 Pa, sputtering power 50W, Ar flow rate 25sccm, deposition pressure 0.1Pa, substrat...

Embodiment 3

[0041] The micron / nano-scale BiOCl film material prepared in this embodiment uses a conductive transparent glass ITO as the substrate 1, and a metal bismuth film 2 is deposited on the substrate 1. The metal bismuth film 2 is used as a raw material to form a layer of The BiOCl film 3 composed of two-dimensional BiOCl nanosheets 4 has a thickness of 200 nm.

[0042] First, use conductive transparent glass ITO as substrate 1, use acetone, alcohol, and deionized water as cleaning agent, each ultrasonically clean for 10 minutes, then take it out and dry it with nitrogen, then dry it in a vacuum oven at 120°C for 1 hour, and take it out after cooling. . Magnetron sputtering is used to deposit metallic bismuth film 2 on the conductive transparent glass ITO treated as above. The deposition condition: background pressure 1×10 -5 Pa, sputtering power 50W, Ar flow rate 25sccm, deposition pressure 0.1Pa, substrate temperature 250°C, deposition time 600s. Then put the deposited metal bismuth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com