Supercritical polymerization preparation method and application of water-soluble solid styrene-acrylic resin

A styrene-acrylic resin and water-soluble technology, which is applied in the field of supercritical polymerization and supercritical polymerization preparation of water-soluble solid styrene-acrylic resin, can solve the problems of insignificant inhibition of esterification reaction, blockage of polymer pipes, increased pressure and the like , to achieve the effect of less volatile matter, good transparency and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 24Kg of styrene, 36Kg of α-methylstyrene, 32Kg of acrylic acid, 6Kg of isooctyl acrylate, 1Kg of α-methylstyrene dimer and 1Kg of peroxide to a 200L stirred reactor. tert-butyl 2-ethylhexanoate, close the autoclave. Open the air inlet, first blow carbon dioxide into the reactor to discharge the air in the reactor, close the valve, then start stirring, and heat the reactor; when the temperature rises to 60°C, a certain amount of Liquid carbon dioxide fully dissolves the monomer; when the temperature rises to 110°C, open the carbon dioxide cylinder, add carbon dioxide to the reaction kettle to the design reaction pressure, and set the reaction kettle pressure to 8MPa, 12MPa, 18MPa, and 20MPa respectively for synthesis experiments , After a reaction time of 1.5h, open the exhaust valve and slowly drop to normal pressure to obtain a white loose powdery solid styrene-acrylic resin, whose product numbers are A-1, A-2, A-3, and A-4.

[0028] Under different reaction press...

Embodiment 2

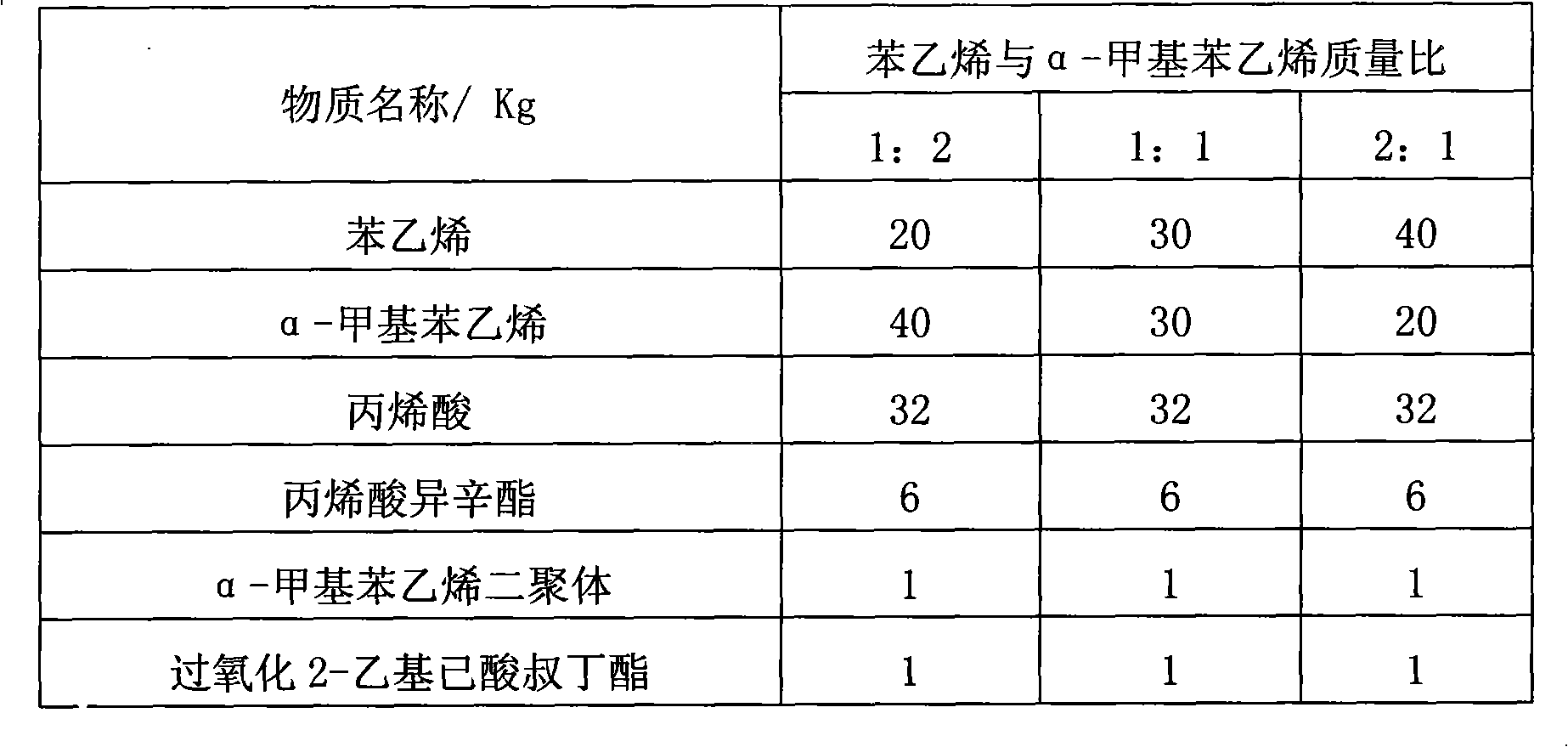

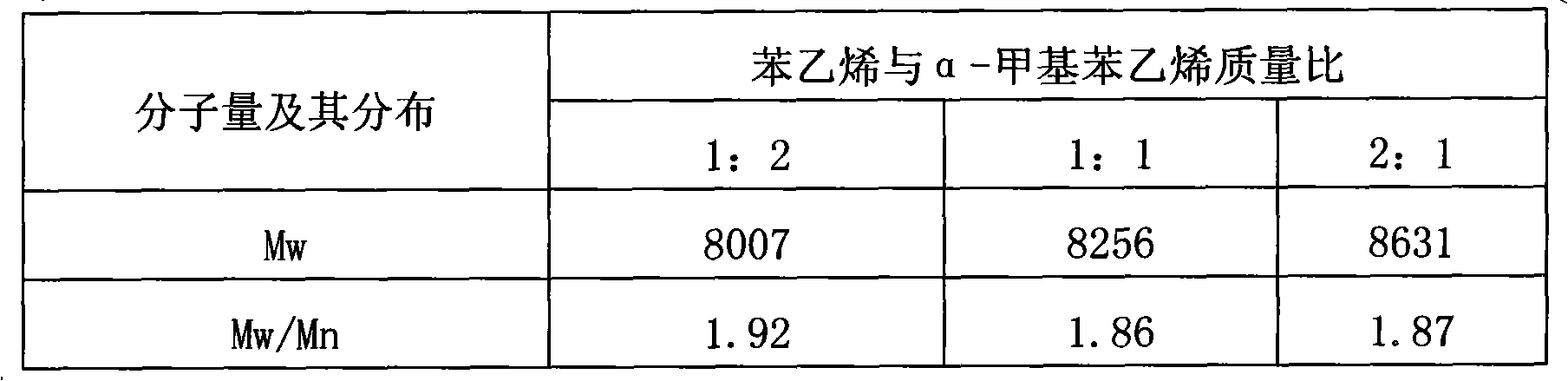

[0030] In this embodiment 1, the mass ratio of styrene and α-methylstyrene is changed by 1:2, 1:1, 2:1 respectively, and the amount of acrylic acid, isooctyl acrylate, chain transfer agent and initiator Remaining unchanged, the reaction pressure of the control system is 18MPa, the reaction temperature is 110°C, and the reaction time is 1.5h. The specific operation method is the same as in Example 1, and the numbers of the obtained solid styrene-acrylic resins are respectively B-1, B-2, and B -3. The synthetic formula is listed in Table 2, and the molecular weight and distribution of the synthetic products are listed in Table 3.

[0031] In embodiments 1 and 2, the styrene monomer can be one or more of styrene, α-methylstyrene, p-methylstyrene, o-chlorostyrene; The amount of styrene monomer accounts for 10-70% of the total mass of raw materials used for preparing the resin. The acrylic monomer can be acrylic acid and its esters; the acrylic acid is one or more of acrylic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com