Method for preparing self-supporting conductive polymer film and composite film and application

A technology of conductive polymer and polymer film, applied in cable/conductor manufacturing, conductor, circuit and other directions, can solve the problems of complex preparation process, high substrate requirements, film thickness and morphology cannot be accurately controlled, etc. Controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] In order to overcome the defects in the preparation of traditional conductive polymer films, the present invention conceives and provides a method for preparing self-supporting conductive polymer films and composite films, and creates a novel and simple preparation method for the application of conductive polymer films . The detailed process can include the following steps:

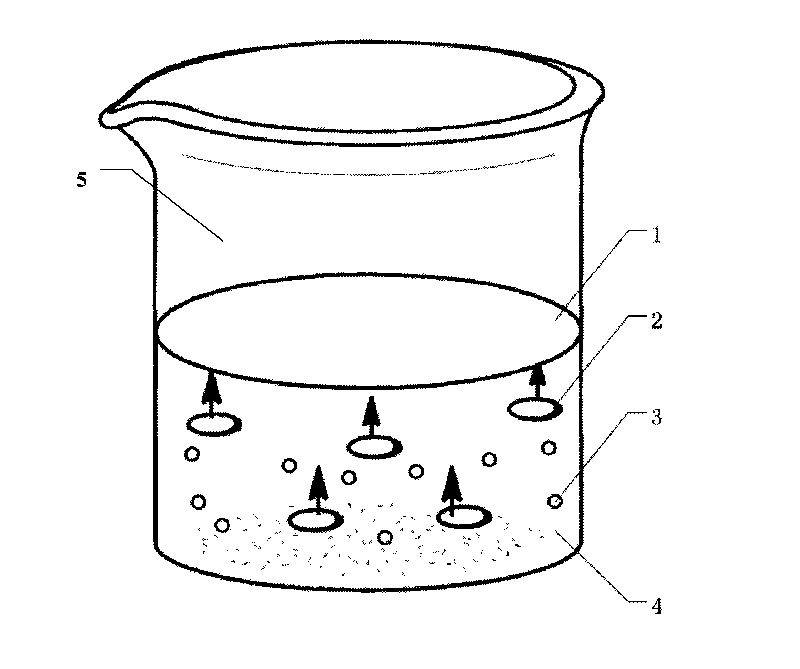

[0018] 1) if figure 1 The simulation schematic diagram of the self-supporting conductive polymer film preparation method shown shows that in the ionic liquid 4 containing the conductive polymer monomer 2, the gas-liquid two-phase interface or the liquid-liquid two-phase interface spontaneously grows to prepare a uniform self-supporting conductive film. The polymer film 1 can control the surface smoothness and thickness of the film by changing the reaction conditions. At the same time, a film with a porous structure can also be prepared, which is the basic feature of the method of the present inve...

Embodiment 1

[0026] Dissolve 43.8 mg of surfactant Brij35 in 1 mL of ionic liquid 1-Ethyl-3-methylimidazolium tetrafluoroborate, then add 0.5 mL of pyrrole 2 into it and stir for a while, then add a small amount of CuCl 2 After shaking, let it stand for 10 minutes, then add the insoluble CuCl 2 Filter off, and the filtrate is placed in a watch glass and allowed to stand for a period of time. Place the watch glass in distilled water, grow a polypyrrole film on the surface of the ionic liquid and float on the water surface, and take it out to obtain the polypyrrole film.

Embodiment 2

[0028] Dissolve 43.8 mg of surfactant Brij35 in 1 mL of ionic liquid 1-Ethyl-3-methylimidazolium tetrafluoroborate, then add ZnO nanoparticles, disperse the system uniformly, add 0.5 mL of pyrrole 2, stir for a while, add a small amount of CuCl 2 After shaking, let it stand for 10 minutes, then add the insoluble CuCl 2 Filter off, and the filtrate is placed in a watch glass and allowed to stand for a period of time. Place the watch glass in distilled water, grow a polypyrrole film on the surface of the ionic liquid and float on the water surface, and take it out to obtain a polypyrrole composite film doped with ZnO nanoparticles.

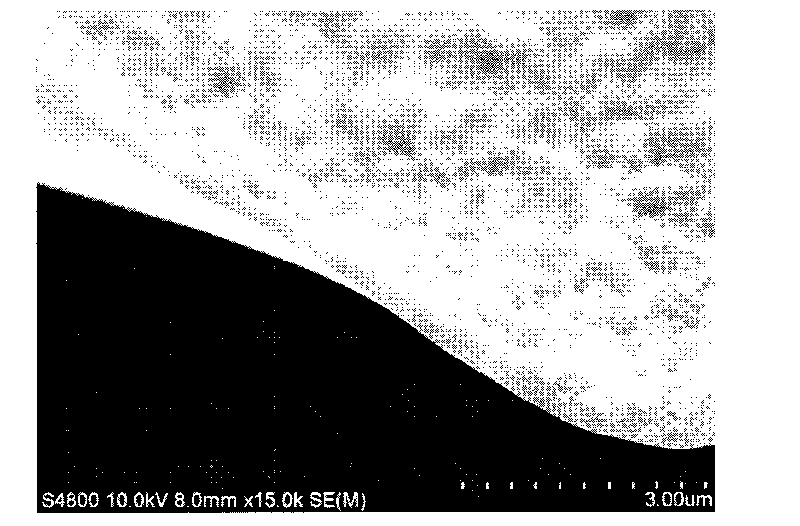

[0029] In summary, the two sides of the conductive polymer film prepared by the method of the present invention can be uniform, symmetrical, or asymmetrical, one side is smooth, the other side is rough and the thickness is controllable (from tens of nanometers to several microns), and the area is not large. limit (such as figure 2 and image 3 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com