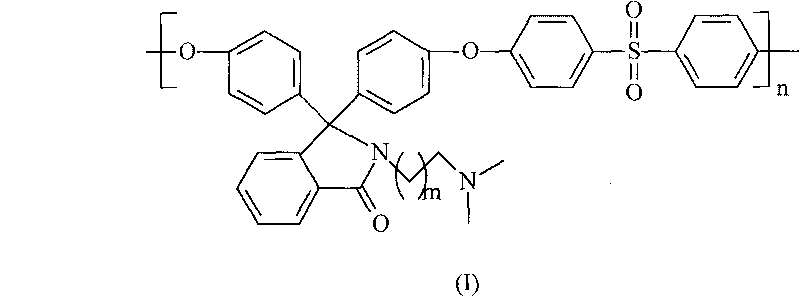

Phenolphthalein polyether sulfone containing tertiary amine side group and preparation method thereof

A technology of tertiary amines and side groups, which is applied in the field of phenolphthalein polyethersulfone and its preparation, can solve the problems of application limitations, low water permeability, protein adhesion, etc., and achieve the effect of low requirements on reaction conditions, low price and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The invention also discloses a preparation method of phenolphthalein polyethersulfone containing tertiary amine side groups, comprising:

[0051] a) adding halogenated organic monomers or nitrated organic monomers, catalysts and solvents to the pre-prepared phenolphthalein bisphenol monomers containing tertiary amine side groups to form a mixed solution;

[0052] b) The mixed solution is reacted under the condition of 80°C-220°C.

[0053] The present invention has no special restrictions on halogenated organic monomers, preferably 4,4'-difluorodiphenyl sulfone, 4,4'-dichlorodiphenyl sulfone, 4,4'-difluorobenzophenone, 4,4' - Chlorobenzophenones or perfluorobiphenyls.

[0054] The present invention has no special limitation on the catalyst, preferably alkaline earth metal salt or alkali metal salt, more preferably sodium carbonate, potassium carbonate or cesium carbonate.

[0055] The present invention has no special limitation on the solvent, preferably N,N-dimethylfo...

Embodiment 1

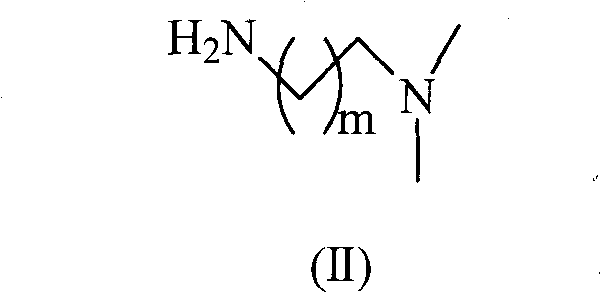

[0104] Add 0.1mol phenolphthalein and 0.1mol N,N-dimethylaminopropylamine to a three-necked flask equipped with a mechanical stirrer, a condenser and a water separator; feed nitrogen into the three-necked flask, and slowly raise the temperature to 120°C, Make the materials in the three-necked bottle react to generate PPH-TA;

[0105] Add 0.1mol PPH-TA, 0.1mol 4,4'-dichlorodiphenyl sulfone, 0.2mol anhydrous potassium carbonate, 138mL dimethyl sulfoxide, 70mL toluene into a three-necked flask equipped with mechanical stirring, condenser and water separator ;

[0106] Introduce nitrogen into the three-necked bottle, and gradually raise the temperature of the three-necked bottle to 150°C to reflux the toluene. After reflux for 4 hours, gradually distill the toluene out, slowly raise the temperature to 180°C, and polymerize the materials in the three-necked bottle .

[0107] After reacting for 10 hours, lower the temperature to cool the system to room temperature, add N,N-dimethy...

Embodiment 2

[0110] Add 0.1mol phenolphthalein and 0.1mol N,N-dimethylaminopropylamine to a three-necked flask equipped with a mechanical stirrer, a condenser and a water separator; feed nitrogen into the three-necked flask, and slowly raise the temperature to 120°C, Make the materials in the three-necked bottle react to generate PPH-TA;

[0111] Add 0.1mol PPH-TA, 0.1mol 4,4'-difluorodiphenyl sulfone, 0.2mol anhydrous potassium carbonate, 138mL dimethyl sulfoxide, 70mL toluene into a three-necked flask equipped with mechanical stirring, condenser and water separator ;

[0112] Introduce nitrogen into the three-necked bottle, and gradually raise the temperature of the three-necked bottle to 150°C to reflux the toluene. After reflux for 4 hours, gradually distill the toluene out, slowly raise the temperature to 180°C, and polymerize the materials in the three-necked bottle .

[0113] After reacting for 10 hours, lower the temperature to cool the system to room temperature, add N,N-dimethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com