Gadolinium-containing silicon dioxide nanosphere magnetic resonance contrast agent and preparation method thereof

A magnetic resonance contrast agent, silicon dioxide technology, applied in the direction of nuclear magnetic resonance/magnetic resonance imaging contrast agent, emulsion delivery, drug delivery, etc., can solve poor particle size distribution control, limit the application of contrast agents, and irregular morphology problems such as high particle size uniformity, regular shape, and reduced gadolinium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

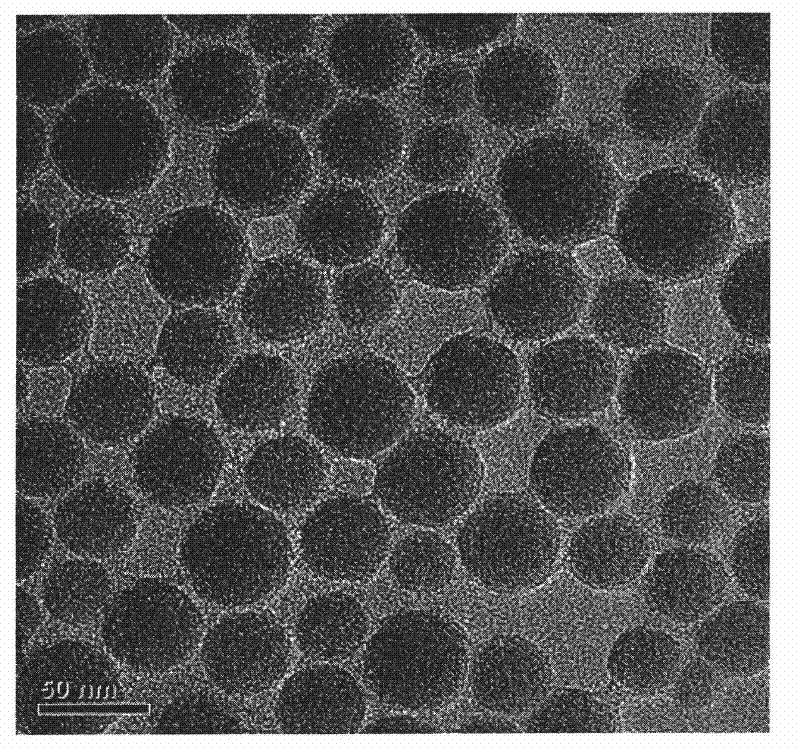

Embodiment 1

[0033] Example 1: Mix 7.5ml of oil phase cyclohexane and 1.8ml of surfactant polyethylene glycol octyl phenyl ether (Triton X-100), and stir vigorously until uniform, and then add 150μl of gadopentetate dimethylglucoside After the amine solution (469.01mg / ml) and 240μl of ammonia (25wt%) are mixed uniformly, they are slowly dropped into the oil phase under ultrasonic and stirring conditions of 400rpm, and the ultrasonic stirring is continued for 30 minutes until the microemulsion is formed. Under stirring at a speed of 400 rpm, slowly add 100 μl of ethyl orthosilicate (TEOS), and continue stirring for 3 hours. The microemulsion system was placed in the backlight and aged at room temperature for 24 hours. After the reaction is complete, add acetone to demulsify, centrifuge at high speed and discard the supernatant, then wash with absolute ethanol for at least 5 times, ultrasonically disperse in deionized water, freeze-dried to obtain the water-soluble doped gadolinium preparatio...

Embodiment 2

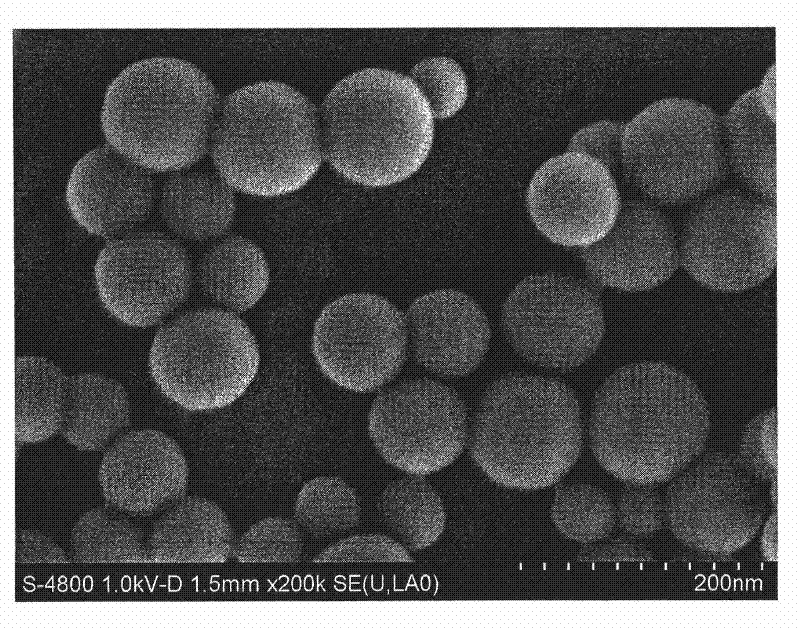

[0034] Example 2: Mix 10ml of oil phase liquid paraffin, 100μl of surfactant sorbitol stearate (Span80), and stir vigorously until uniform, then add 10μl of gadoterate meglumine solution (50mg / ml) and 50μl of hydrogen After the sodium oxide solution (5wt%) is uniformly mixed, it is slowly dropped into the oil phase under ultrasonic and stirring conditions of 100 rpm, and ultrasonic stirring is continued for 30 minutes until the microemulsion is formed. Under stirring at a speed of 100 rpm, 50 μl of ethyl orthosilicate (TEOS) was slowly added, and stirring was continued for 3 hours. The microemulsion system was placed in the backlight and aged at room temperature for 24 hours. After the reaction is complete, add acetone to demulsify, centrifuge at high speed and discard the supernatant, then wash with absolute ethanol for at least 5 times, and then ultrasonically disperse in deionized water to obtain water-soluble silica doped with gadolinium preparation Nano microsphere suspen...

Embodiment 3

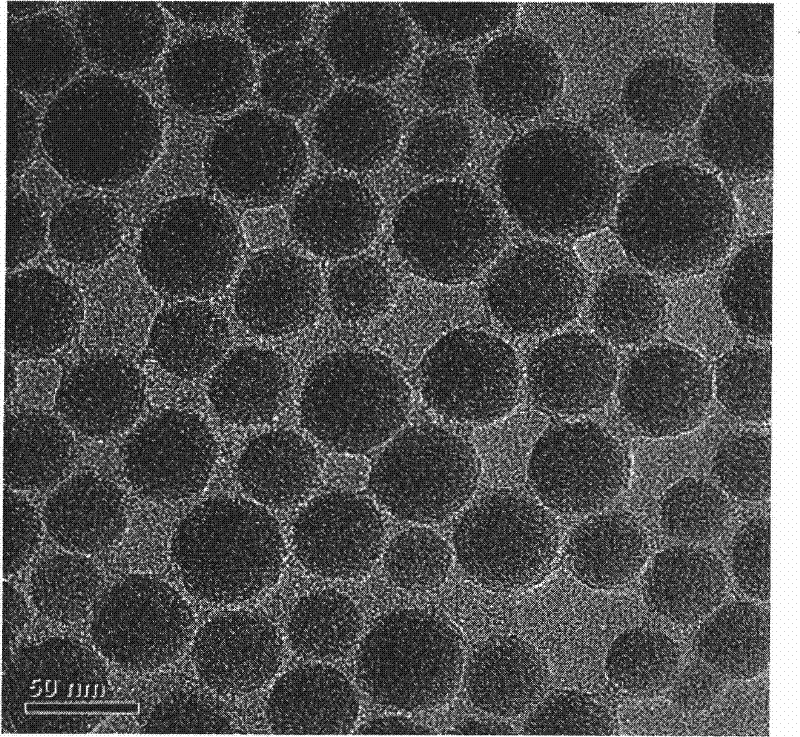

[0035] Example 3: Mix 10ml of oil phase petroleum ether, 4ml of surfactant sorbitol stearate (Span80), and stir vigorously until uniform, then mix 800μl of Gd-DTPA chelate solution (1000mg / ml) and 1ml of hydrogen After the sodium oxide solution (30 wt%) is uniformly mixed, it is slowly dropped into the oil phase under ultrasonic and stirring conditions of 500 rpm, and ultrasonic stirring is continued for 30 minutes until the microemulsion is formed. Under stirring at a speed of 500 rpm, slowly add 1 ml of ethyl orthosilicate (TEOS) and continue stirring for 3 hours. The microemulsion system was placed in a dark place and aged at room temperature for 48 hours. After the reaction is complete, add acetone to demulsify, centrifuge at high speed and discard the supernatant, then wash with absolute ethanol for at least 5 times, ultrasonically disperse in deionized water, freeze-dried to obtain the water-soluble doped gadolinium preparation Silica nano-sphere powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com