Method and device for removing sulfur dioxide and nitric oxide by combining dual-shaft clash smoke gas

A technology for sulfur dioxide and nitrogen oxides, applied in chemical instruments and methods, separation methods, air quality improvement, etc., to achieve high comprehensive efficiency, improved uniformity, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for combined removal of sulfur dioxide and nitrogen oxides from flue gas with biaxial collision flow,

[0036] After dedusting the polluted flue gas containing sulfur dioxide and nitrogen oxides, it enters the heat exchanger and cools down to 100 ° C ~ 110 ° C.

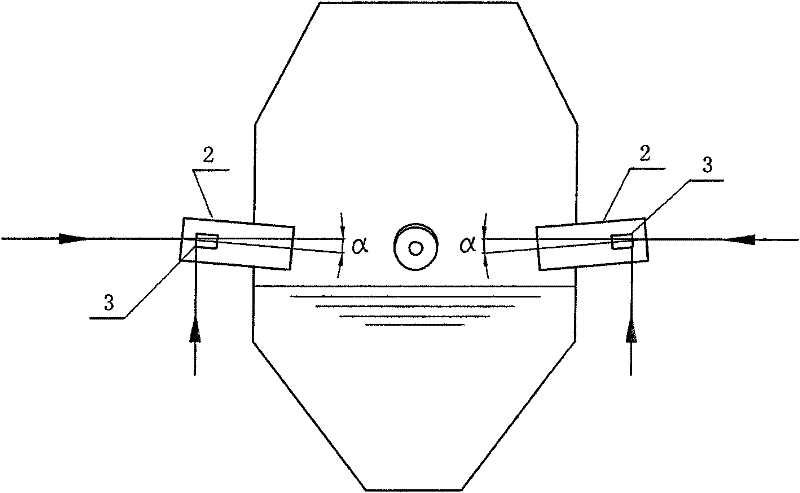

[0037] Then the flue gas after dust removal and cooling enters the biaxial colliding flow premixing tube. In the biaxial colliding flow premixing tube, the flue gas is first mixed with the atomized urea / ammonia water mixed with catalytic additives. The mixed solution is pre-mixed with gas and liquid, and the temperature of the absorption liquid is controlled at 30°C-80°C, and the liquid-gas ratio is 1.5-6L / m 3 , the mass concentration of the ammonia solution is 2% to 10%, the mass concentration of the urea solution is 2% to 6%, the pH value of the absorption solution is maintained at 4.8 to 9, and the additive with catalytic effect is potassium bromide, ammonium bromide, Potassium chloride, ammonium c...

Embodiment 2

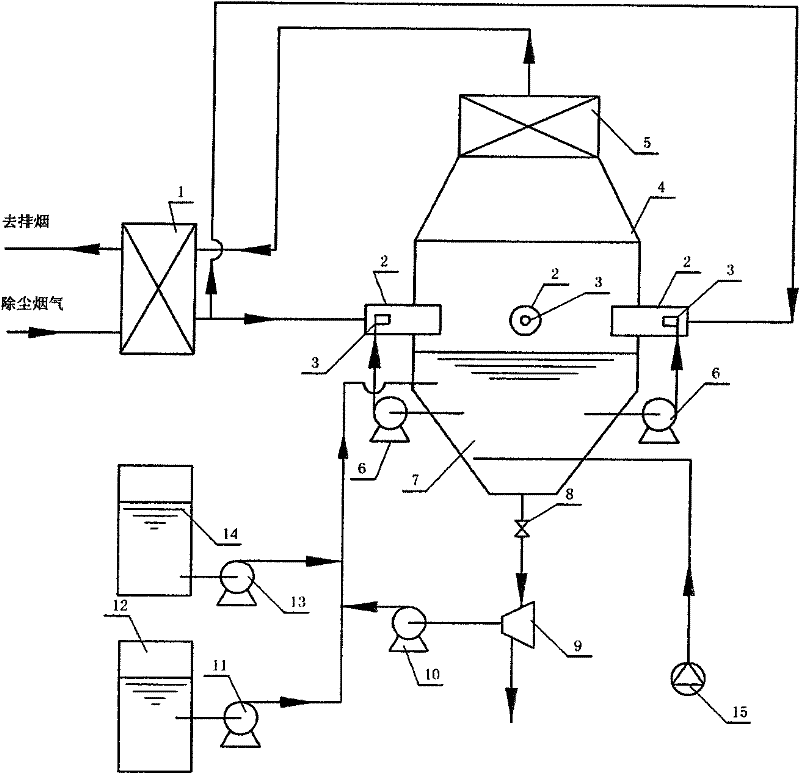

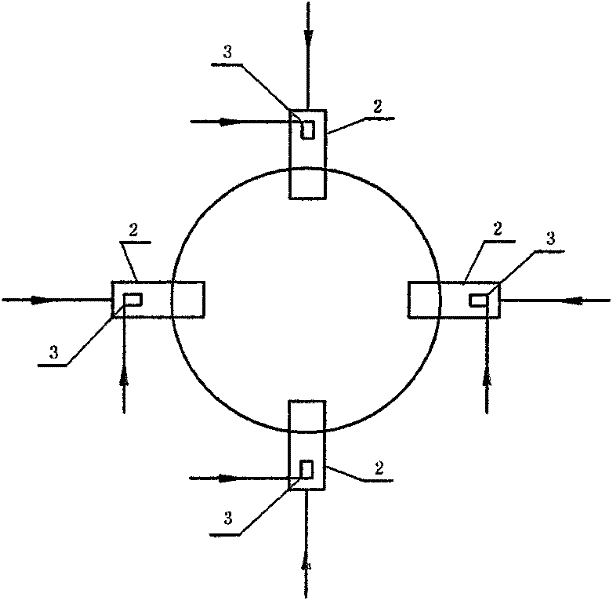

[0041] A device for implementing the method for the combined removal of sulfur dioxide and nitrogen oxides from flue gas with twin-shaft colliding flow described in Example 1, consisting of a heat exchanger 1, a biaxial colliding flow premixing tube 2, and a colliding flow reactor Main body 4, high-efficiency demister 5, absorption liquid circulation pump 6, liquid collection tank 7, valve 8, centrifuge 9, separation liquid pump 10, ammonia water pump 11, ammonia water distribution tank 12, urea solution pump 13, urea solution distribution Composed of a liquid tank 14 and an air compressor 15, the polluted flue gas outlets of the heat exchanger 1 are respectively connected to the flue gas inlets of the biaxial collision flow premixing pipe 2, and the absorption solution is stored in the liquid collection tank 7 and collected The liquid tank 7 is connected to the lower end of the main body 4 of the colliding flow reactor. The biaxial colliding flow premixing pipe 2 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com